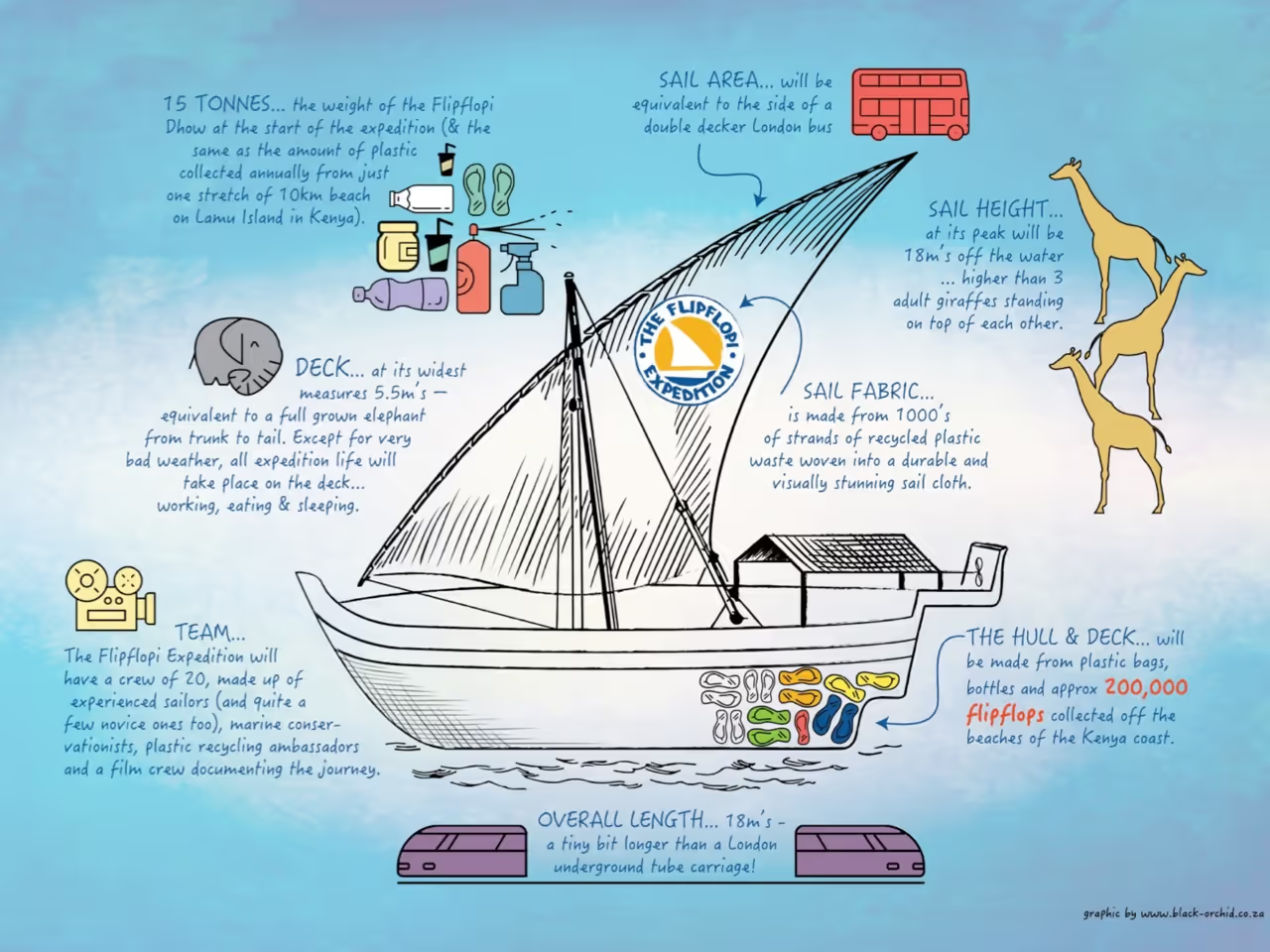

The Flipflopi is a sailing boat constructed from recycled plastic and flip-flops gathered in Kenya.

Here, we share its construction process and insights gained.

Table of Contents

- 1Intro

This boat is a prototype, the first of its kind. The methods used were experimental and imperfect. Use this as a learning tool and for inspiration.

-

How to Build a Boat with Alternative Materials

We began by collaborating with a local boat builder, Ali Skanda from Lamu, who was open to using unconventional materials. He and his team applied their expertise to this new challenge.

It is advisable to partner with experienced boat builders to focus on integrating new materials into existing processes without the added complexity of mastering boat construction.

-

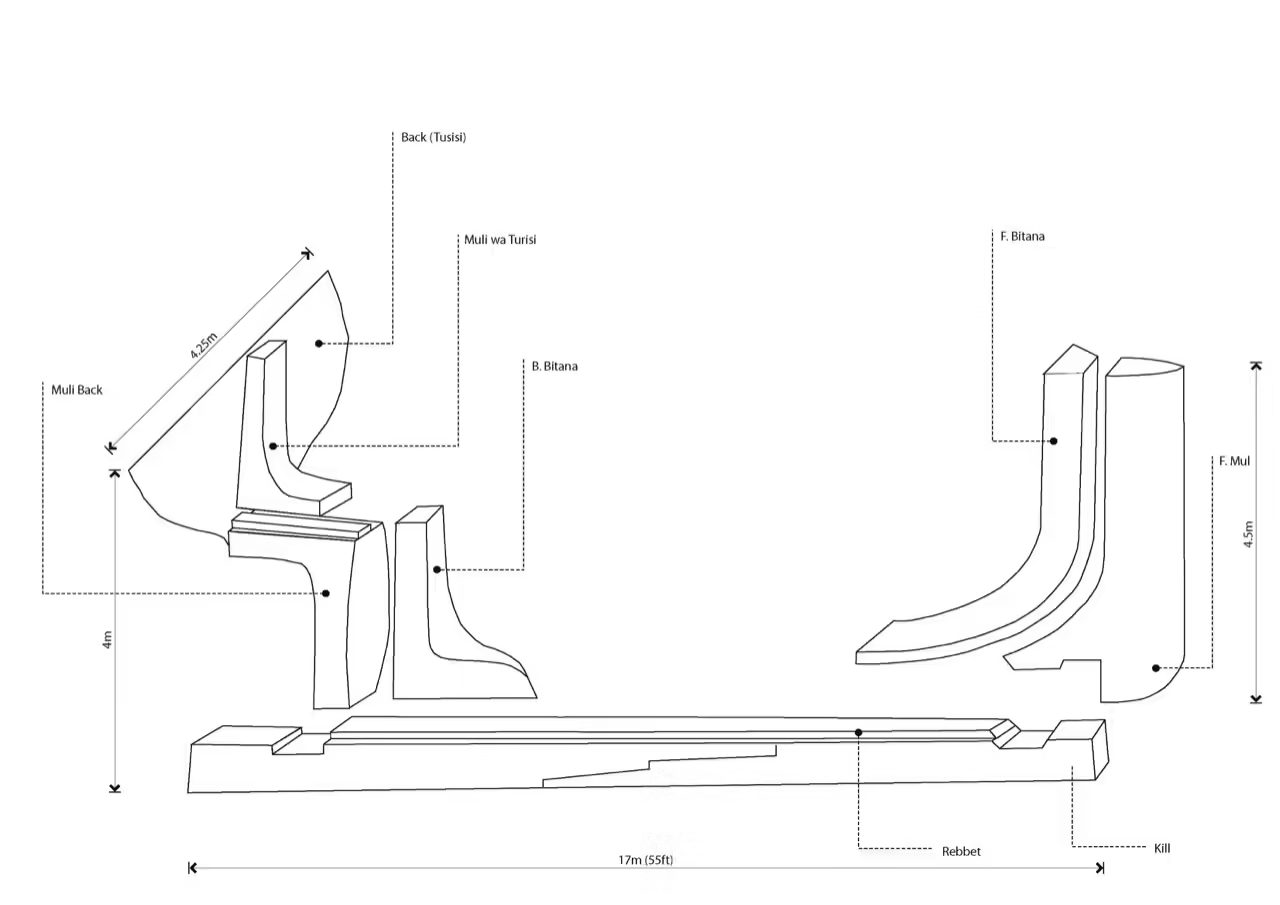

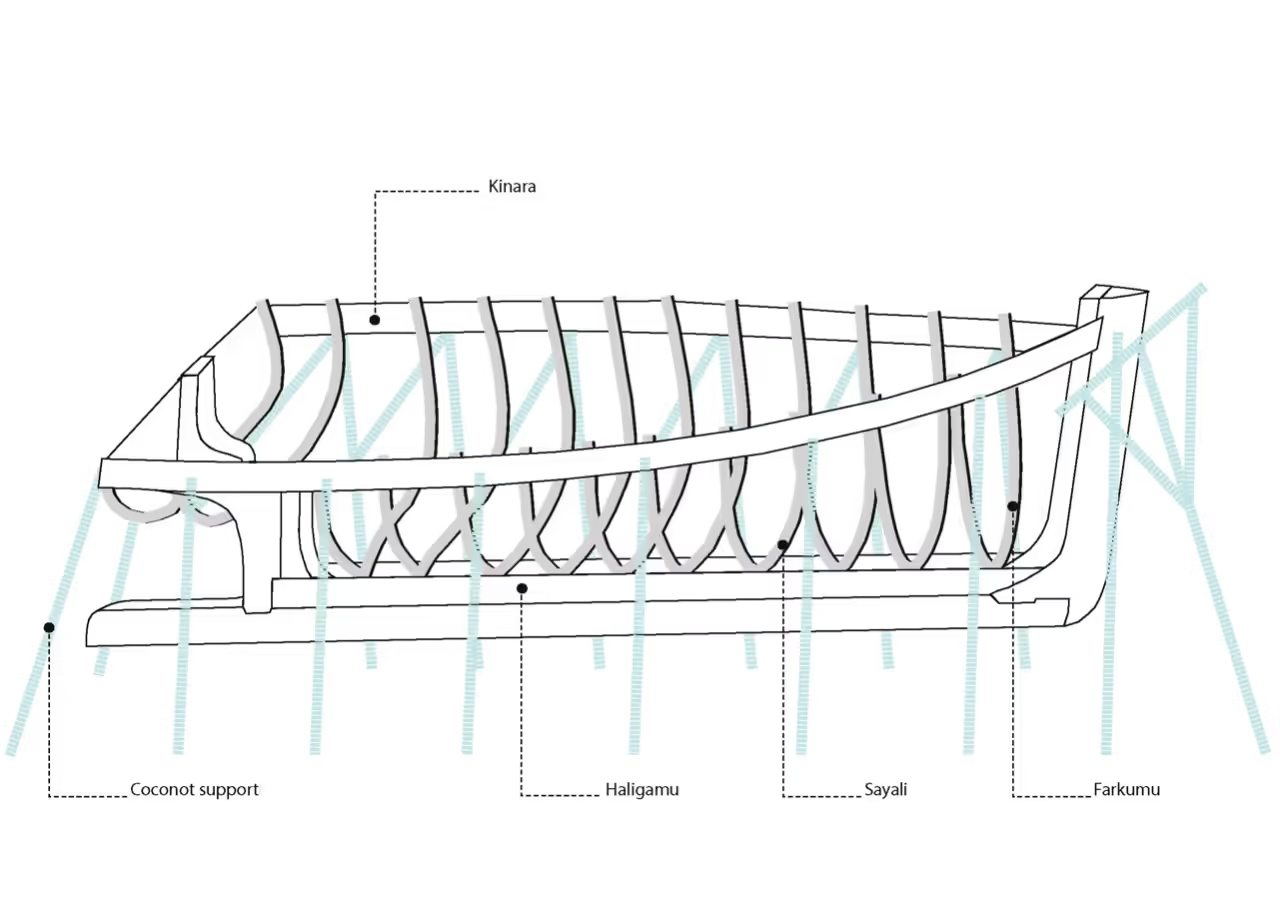

We collaborated with Ali Skanda to design a boat and outline the necessary components and joineries.

The aim is to construct a boat large enough to convey the message against single-use plastic and plastic pollution globally.

Below are sketches providing an overview of the parts.

-

In our effort to produce everything locally in Kenya, a significant challenge was establishing collaborations with manufacturers capable of delivering quality materials consistently.

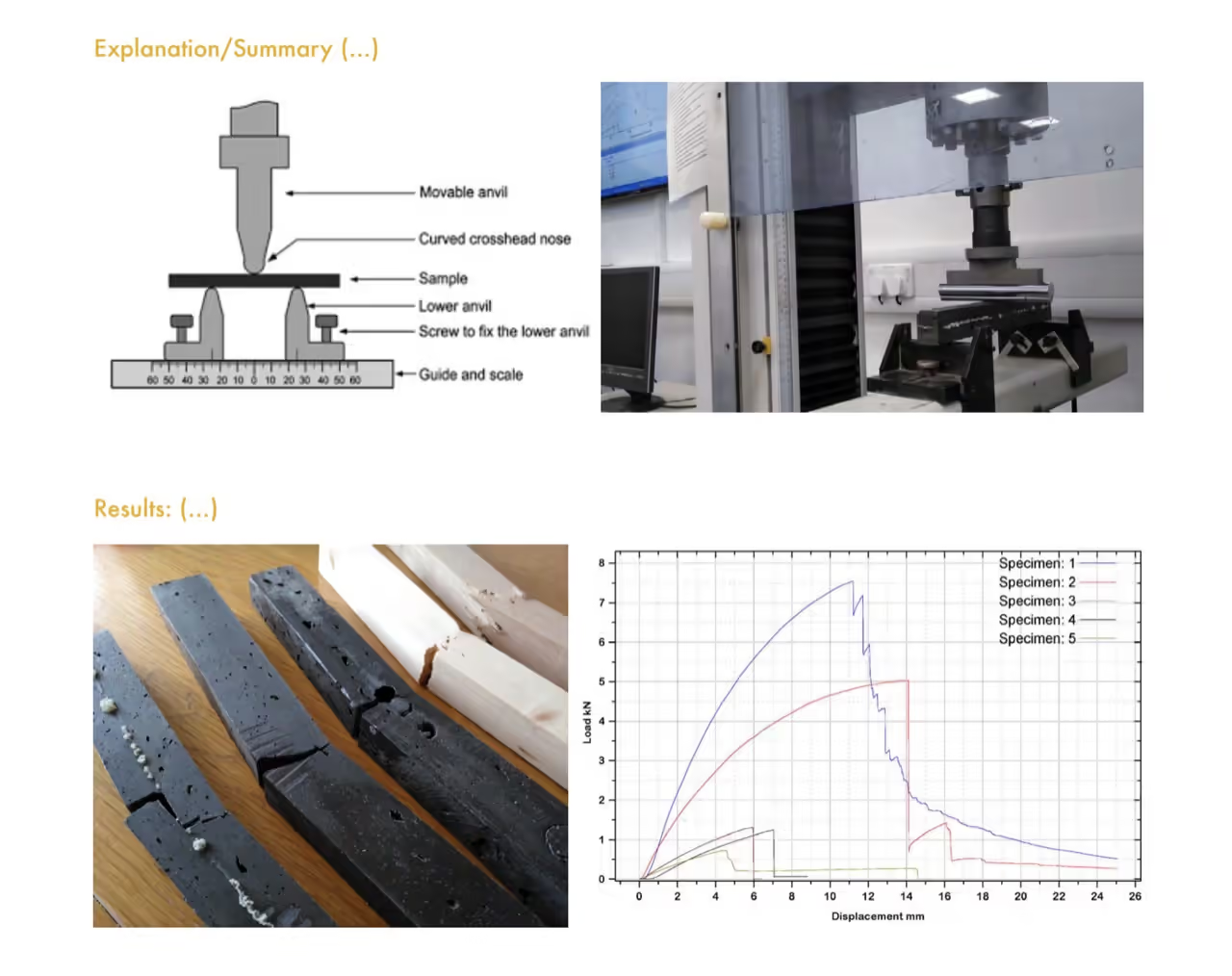

Initially, manufacturers mixed different plastics or added substances like sawdust or sand as stiffeners. We succeeded in having them work with a single type of plastic without additives. An essential step in this process involved obtaining material samples and testing the joinery for boat construction.

Starting with samples can help save time and reduce costs before ordering larger quantities of materials.

-

Having established the procedures, we began manufacturing components for a 79-foot (24-meter) boat. The parts were substantial.

Although the quality was quite basic, it demonstrated feasibility. Given the novelty and significant investment involved, we opted to build a smaller 33-foot (10-meter) prototype first.

Next, we will detail how we created the Flipflopi Dogo ("dogo" means "small" in Kiswahili).

-

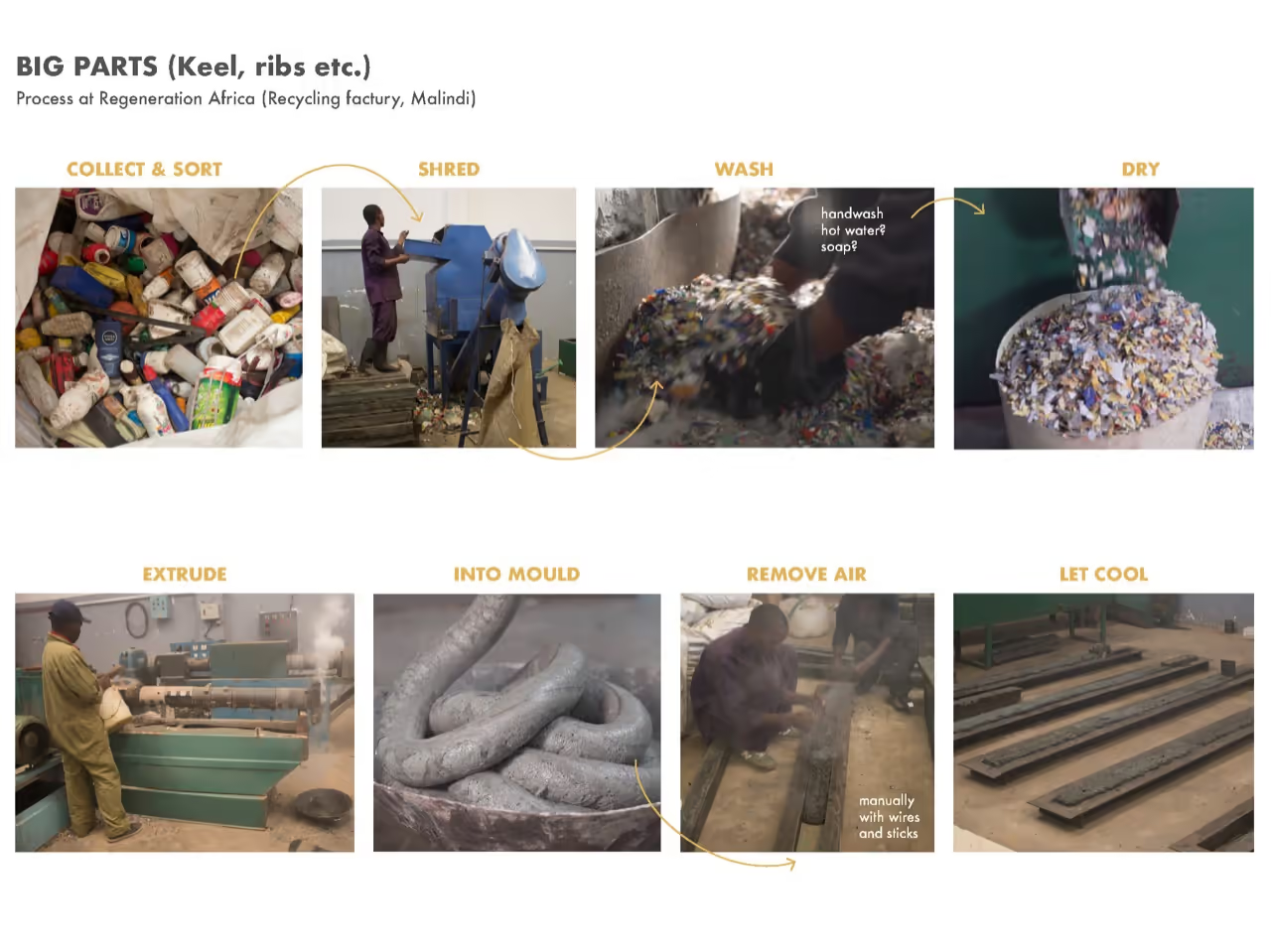

Overview of Production Process

The production of major components like the keel and ribs posed significant challenges. We utilized available resources, acknowledging potential areas for improvement.

We worked with a plastic manufacturer in Malindi known for producing fencing posts and tiles.

Below is an overview of their process. We created over 30 metal molds for various boat parts, using HDPE, a commonly collected material.

Sam and his team were instrumental in exploring different processes and materials.

-

For the planks, we collaborated with manufacturers in Nairobi who also produce fencing posts and other construction materials. It is common to add sawdust to the material to increase stiffness and reduce costs, although this mix is more prone to breaking than pure plastic. After several attempts, we successfully created planks made from 100% recycled plastic. These planks were produced using industrial machines but can also be made with the Extrusion Pro.

-

Certainly. Here is the revised text:

Forty percent of the waste collected on beaches consisted of flip-flops, inspiring the project's name and their inclusion in the boat's design.

The entire boat was covered with sheets of flip-flops, providing a colorful appearance and an additional protective layer resembling a large yoga mat.

These sheets were crafted by local artist James, who cuts the flip-flops into pieces, glues them, and sands them into even sheets.

-

How to Build the Boat

Begin with constructing the keel, ribs, and connection parts, followed by forming the hull with extruded planks, and conclude with the Flipflop sheets.

The boatbuilders adhered to traditional methods, using fundamental tools, where screws were inserted with a hand drill and screwdriver.

This hands-on expertise requires a skilled boatbuilder.

-

The next step involved adding parts from other sailing boats, such as the mast, boom, sail, and ropes. With these additions, the boat was ready for its intended purpose: sailing.

On our maiden voyage, the boat successfully sailed over 310 miles (500 km) from northern Kenya to Zanzibar, safely transporting passengers and capturing interest along the route.

Important: Ensure your boat is seaworthy. You are responsible for the safety of yourself and your passengers.

-

It was a significant endeavor with considerable learning, resulting in a functional boat. However, the process had room for improvement.

During this time, we conducted additional tests and analyzed material properties. A report is available here: Material Analysis Report.

The document shared in Step 1 contains further details.

- 12Join us! ⛵️

Project Update

We have successfully engaged numerous individuals worldwide with our expedition and its narrative, effectively fostering beneficial change.

Our next step is to construct a larger vessel capable of navigating greater distances and reaching a broader audience. This ambitious project presents several challenges, but as Ali Skanda notes, "Kila kitu inawezekana" – everything is possible.

For inquiries or to support our endeavors, please contact theflipflopi@gmail.com or consider supporting us at patreon.com/theflipflopi.

If you create a similar vessel, we encourage you to share your achievements with us.

Tools

- Hand drill (manual screw insertion)

- Screwdriver (traditional assembly)

- Sanding tools (flip-flop sheet preparation)

- Metal molds (30+ for boat components)

- Extrusion Pro (plank production)

Hardware

- Recycled HDPE plastic (primary material)

- 100% recycled plastic planks (local manufacturing)

- Recycled flip-flop sheets (protective outer layer)

- Sailboat components: mast, boom, sail, ropes

- Material testing equipment (sample validation) · Report

Software

No software explicitly mentioned in the production process.

Additional Resources

- Local plastic manufacturers (Malindi/Nairobi partnerships)

- Traditional boatbuilding expertise (Lamu craftsmanship)

- ~~Project Contact~~ · Support

Articles

- Boat made from 100% recycled plastic sets sail in Kenya

- Flip-flop-clad boat brings plastic recycling message to East African coast

- FLIPFLOPI: the world’s first sailing boat made from plastic waste

- The Flipflopi Project: Mitigating Plastic Pollution through Heritage Boat Building

- A sailboat made from flip-flops tackles Africa's largest lake

- Imagining Water 11: The Flipflopi Project

Books

- Flipflopi: How a Boat Made from Flip-Flops Is Helping to Save the Ocean by Linda R. Lodding & Dipesh Pabari (Africa Access Review)

Papers

- Prevalence and characterisation of microfibres along the Kenyan and Tanzanian coast (Northumbria University, EurekAlert)

YouTube

Opensource Designs

- Build a 'Flipflopi' boat - [filtered] Academy

- Flipflopi Boat Build Toolkit