Sheetpress System Updates

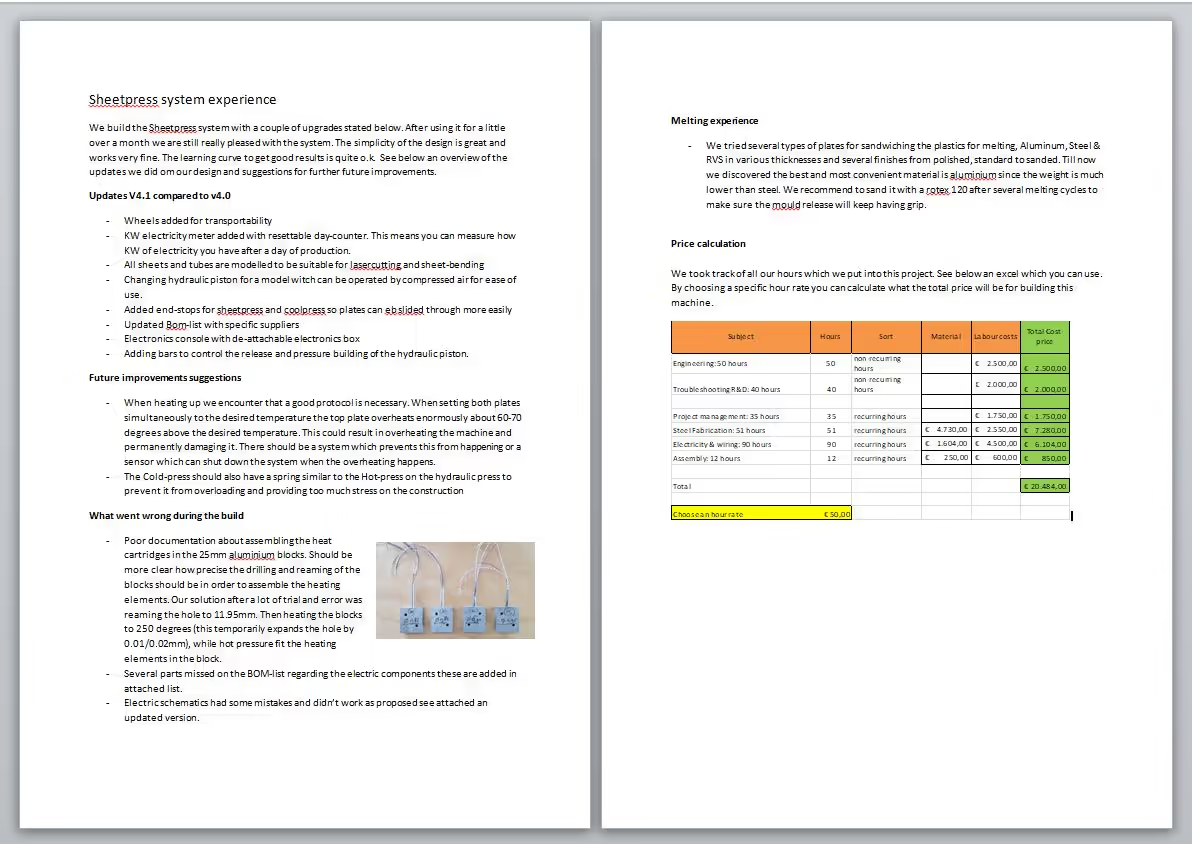

- Provided labor hours for realistic price estimation.

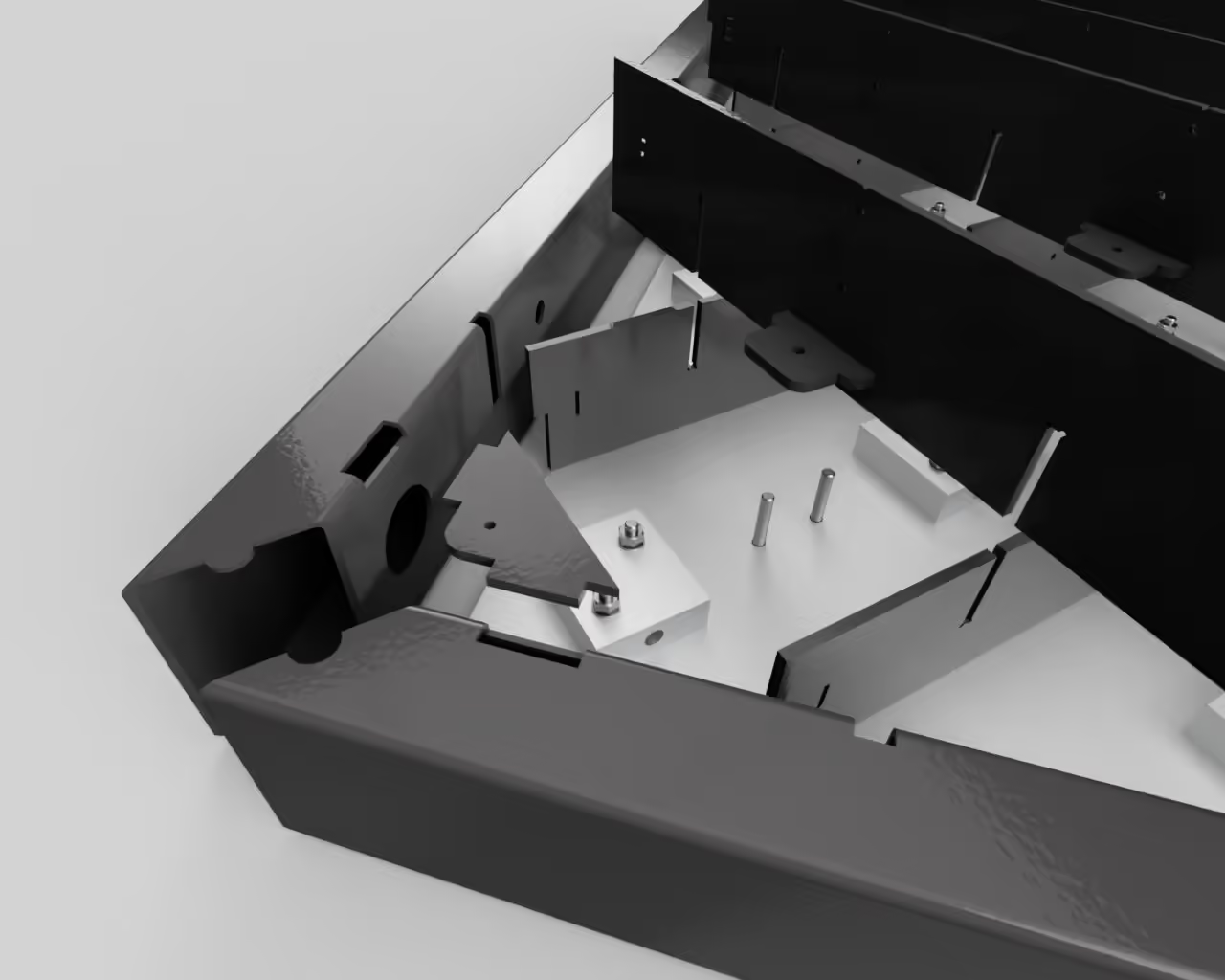

- Modified all sheets and parts for laser cutting and sheet metal bending.

- Updated the bill of materials.

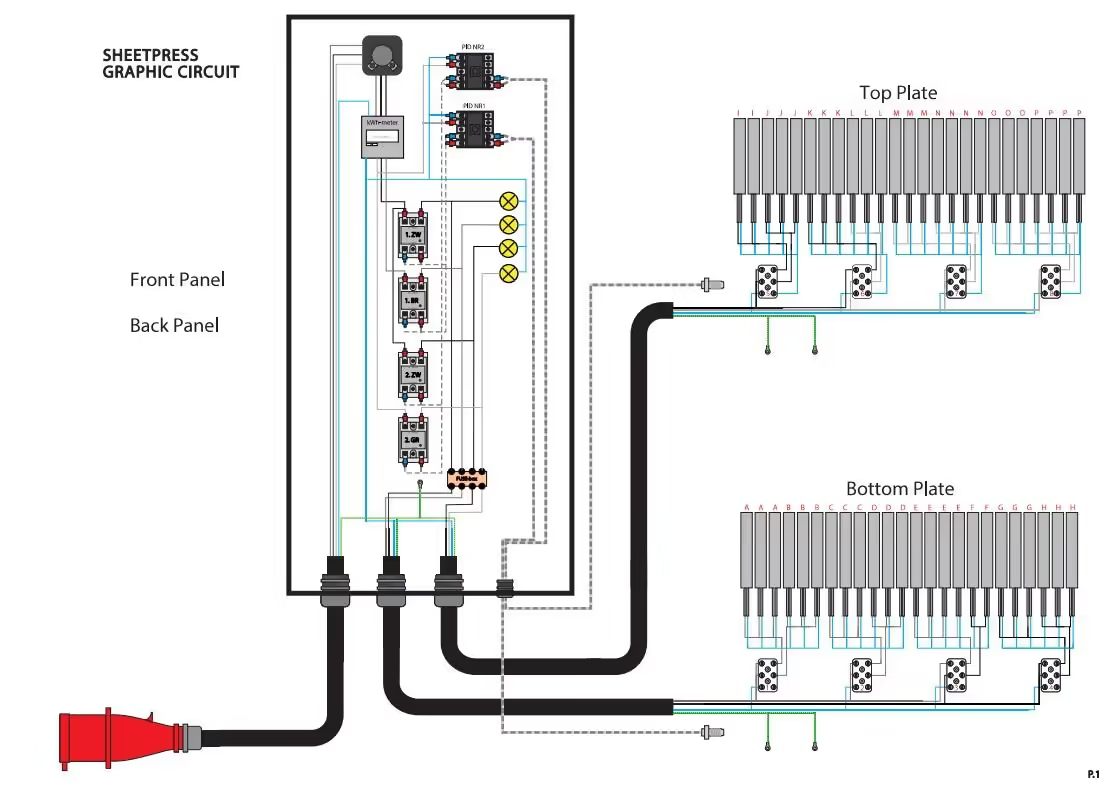

- Revised the circuit diagram.

See files below for more information.

(Last updated: October 23, 2020)

Table of Contents

-

Summary:

This section details:

- Recent updates

- Challenges faced during construction

- Time spent and estimated cost for commercial production

- Suggested improvements

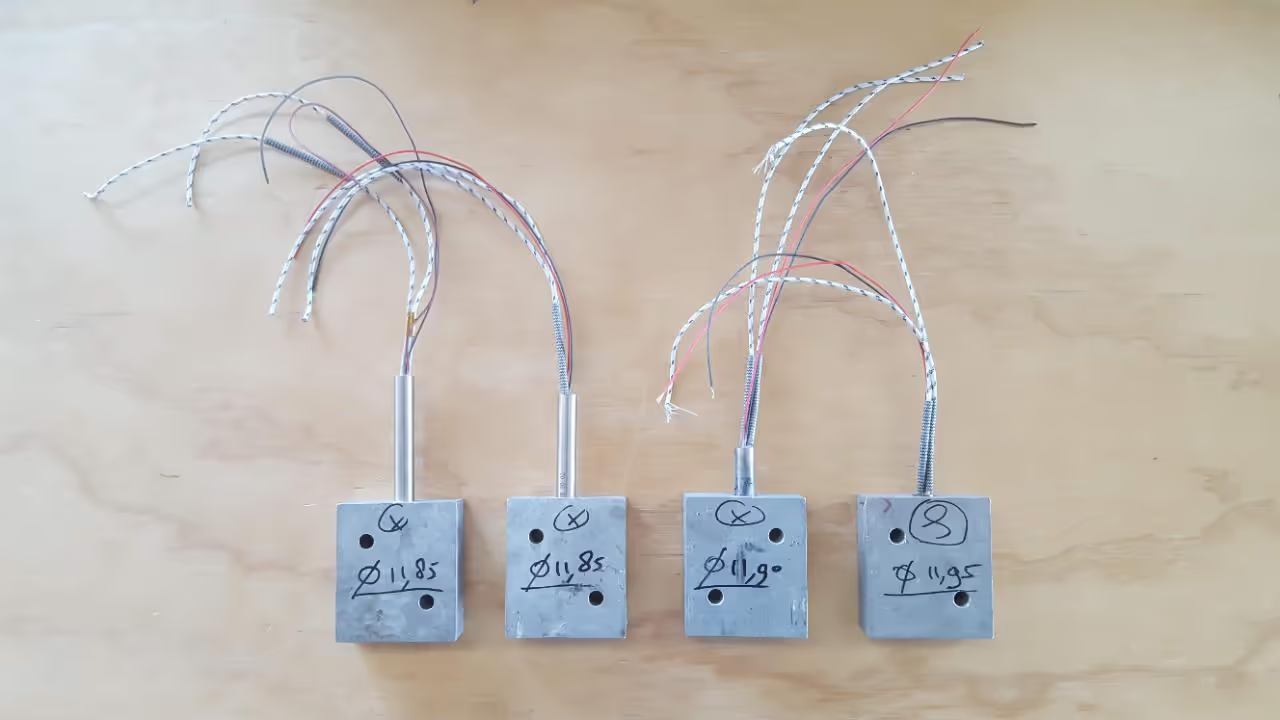

Image Description: The main issue was the initial failure to ream the aluminum block holes to precise measurements.

Solution: After consultation, holes were reamed to 11.95 mm (0.47 in). Blocks were heated to 250°C (482°F) to fit the heating element securely into the holes.

-

All sheets and tubes are designed for laser cutting and bent sheet metal. You can order them as a ready-to-weld kit, eliminating the need for manual cutting of steel tubes. This reduces labor as the parts fit easily and are numbered.

-

We revised the electrical circuit diagram and updated the Bill of Materials with our selected suppliers.

A kWh meter has been added to reset at the start of each day for efficient monitoring of energy consumption, allowing calculation of CO2 emissions per plastic plate.

Signal lights have been installed for each circuit to provide visual feedback when active. We also integrated ceramic fuses to protect heating groups from short circuits and manage heat effectively.

-

Upon completion, numerous opportunities arise.

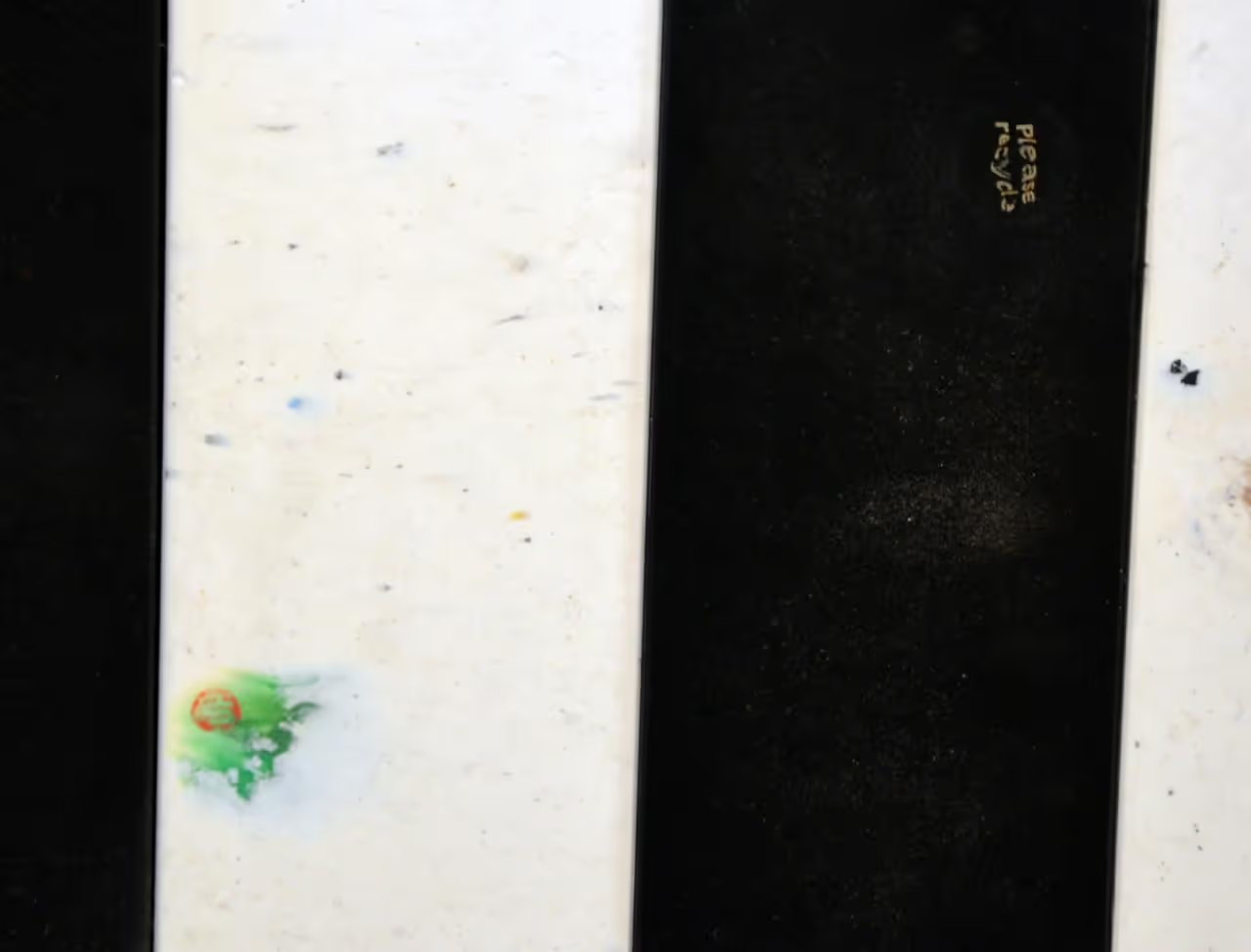

Our initial commercial project was with The Student Hotel in Delft. They requested a design for their interior. Utilizing post-production HDPE plastic, we crafted the black and white cladding for their bar. The client provided their waste streams, primarily HDPE bottle caps from soda bottles, which we melted to form the plates.

-

The sheetpress allows the bending of solid surfaces. We used numerous PET plastic plates from Smile Plastics in England. The Sheetpress facilitated the easy bending of these plates for rounded bars.

Tools

- Reaming tool (11.95 mm precision)

- Welding equipment

- Temperature measurement tool (250°C monitoring)

Software

- CAD software (circuit & parts design)

- Spreadsheet software (Bill of Materials management)

Hardware

- Laser cutter (sheet & tube cutting)

- Sheet metal bender

- Heating element (250°C-capable)

- kWh meter (energy consumption tracking)

- Ceramic fuses & signal lights (circuit protection/feedback)

Suppliers

- Smile Plastics (PET plates)

- The Student Hotel (HDPE waste stream partner)

Links reflect explicitly mentioned suppliers. Hardware focuses on critical systems from the tutorial's technical updates.

Articles

- https://www.[filtered].earth/news/sheetpress

- https://fablabbcn.org/blog/tech-for-good/the-precious-plastic-recycling-revolution

- https://www.huaaoplastics.com/resources/the-ultimate-guide-to-the-precious-plastic-sheetpress.html

Books

Papers

- https://github.com/uwo-fast/desktop-sheet-press

- https://cfsd.org.uk/wp-content/uploads/2020/07/PP_Report_Final_2020-07-04.pdf

Youtube

Opensource Designs

- https://community.preciousplastic.com/library/sheetpress-v4--fiction-factory-version

- https://github.com/uwo-fast/desktop-sheet-press

- https://www.orcular.org/orcuscooter-en

- https://community.preciousplastic.com/library/continuously-produce-sheets

- https://community.preciousplastic.com/library/set-up-a-sheetpress-workspace

- https://community.preciousplastic.com/library/15m-sheetpress-system---designed-for-disassembly