Tutorial: Designing and Printing a Phone Cover Mold with a Resin Printer

This guide outlines the process of designing and printing a phone cover mold using a resin printer. It includes essential steps for creating a mold and offers useful tips on mold design, resin printing, and manufacturing.

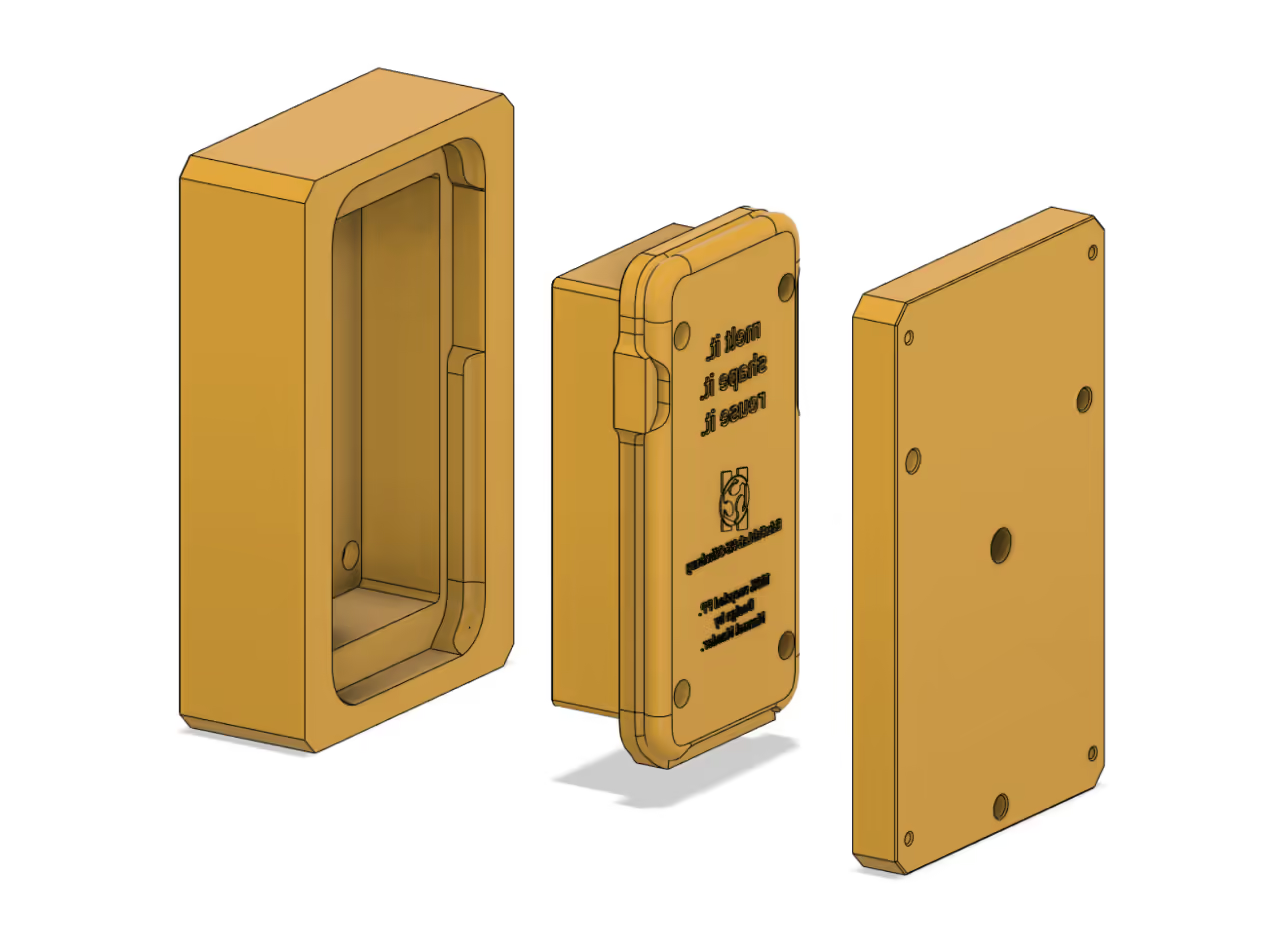

The zip file contains:

- 3D files - SLA phone cover mold (step)

- 3D files - SLA phone cover mold (stl)

- Readme with relevant links (txt)

- Technical drawing of the mold (pdf)

Table of Contents

-

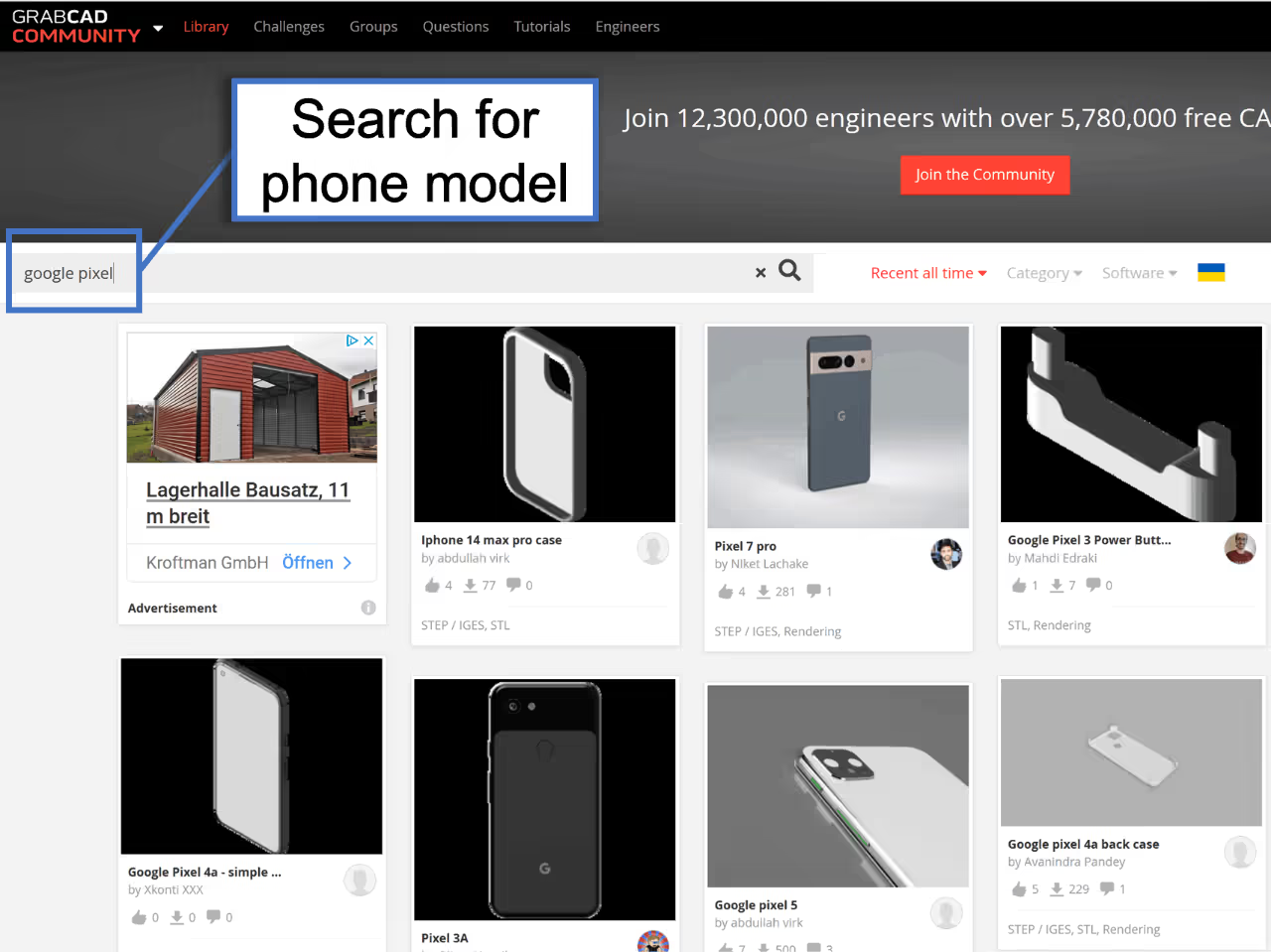

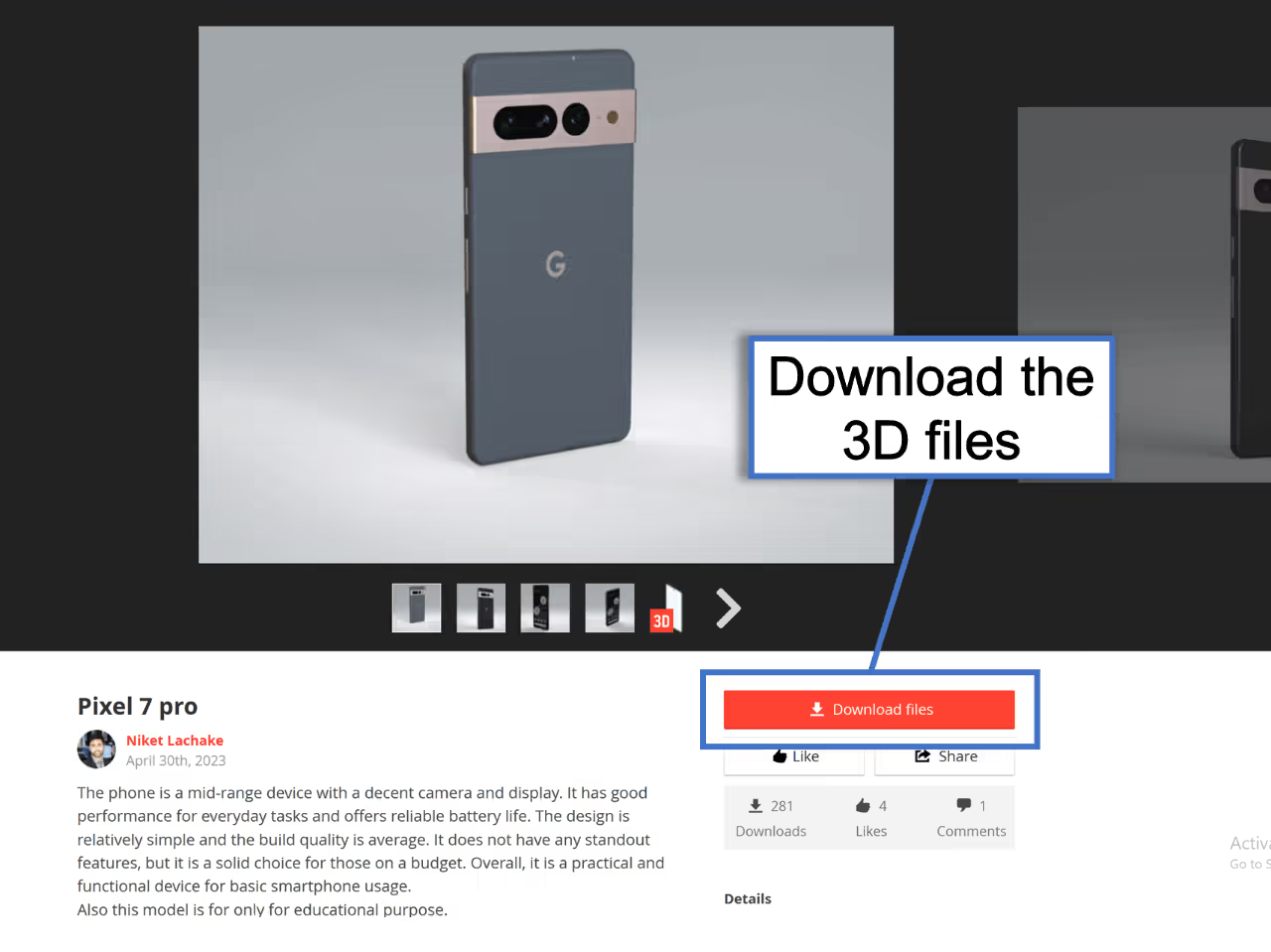

Before modeling the mold, obtain a 3D model of the phone case you intend to create. Start by locating the phone model online, utilizing a CAD library such as GrabCAD.

- Visit GrabCAD and search for your desired phone model.

- Download the model, preferably in STEP format.

- Open the model in your CAD software.

Alternative CAD libraries are available, but GrabCAD frequently offers a wide range of 3D files. Registration allows free downloads.

-

To design a phone cover, begin by downloading the phone model. Use this model to create the cover shape and mould. Fusion360 is a suitable 3D design software for all skill levels.

Two instructional videos can guide you in using Fusion360 for this project:

-

"Product Design Online" offers a step-by-step tutorial on designing a phone case model. Watch here

-

Lars Christensen's channel provides a three-part series on creating a mould. Watch here

Alternatively, pre-made phone cover models are often available on GrabCad, which can save time in the design process.

-

-

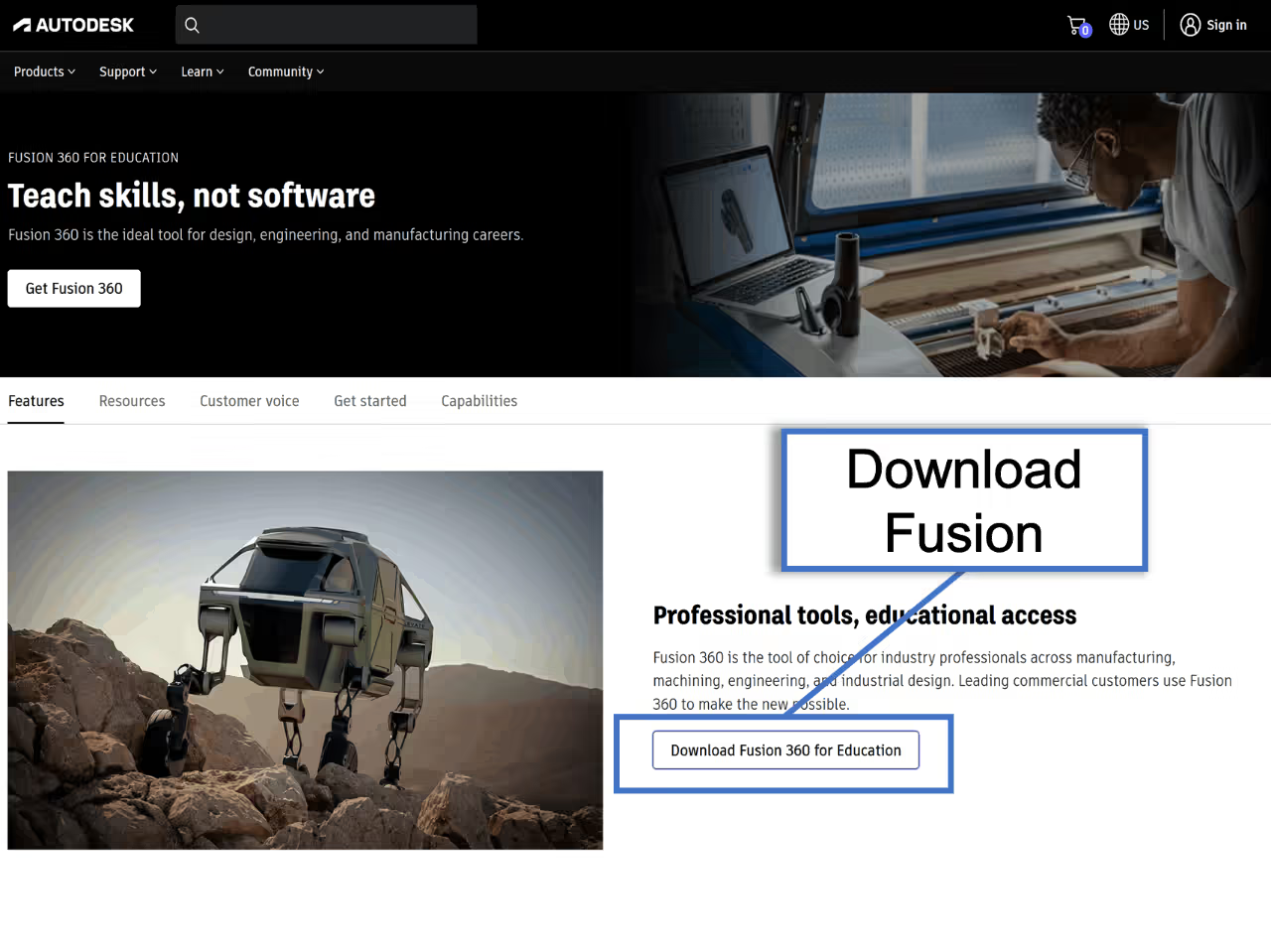

Fusion 360 is a robust software utilized for various projects since 2018. While it is not free, there are options to bypass the subscription cost.

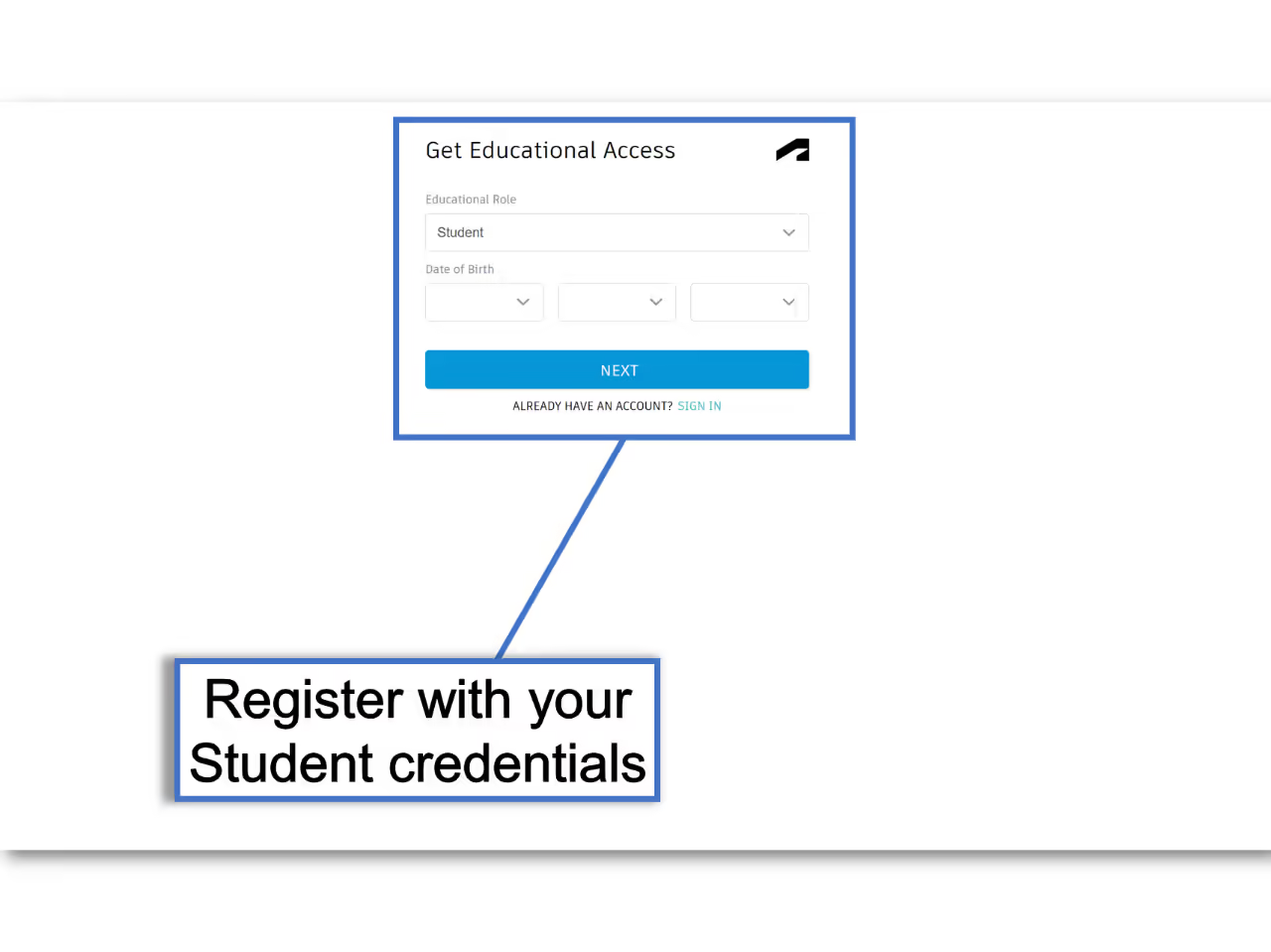

Students at universities can acquire a free educational license valid for the duration of enrollment by submitting proof of their status.

Alternatively, a hobbyist version is available with some restrictions on file formats for import and export.

Download the educational version here: autodesk.com/products/fusion-360/education

-

Once the mold is designed, it can be 3D printed using an SLA printer, which cures liquid resin into solid layers with light. If a printer is unavailable, consider online manufacturing services.

Make it yourself:

-

Prepare your model by slicing it into layers with software like ChiTuBox. Select a high-temperature resin for the mold.

-

Pour the resin into the tank and start the print. Refer to available tutorials for SLA printer usage.

-

Wait for the print to complete.

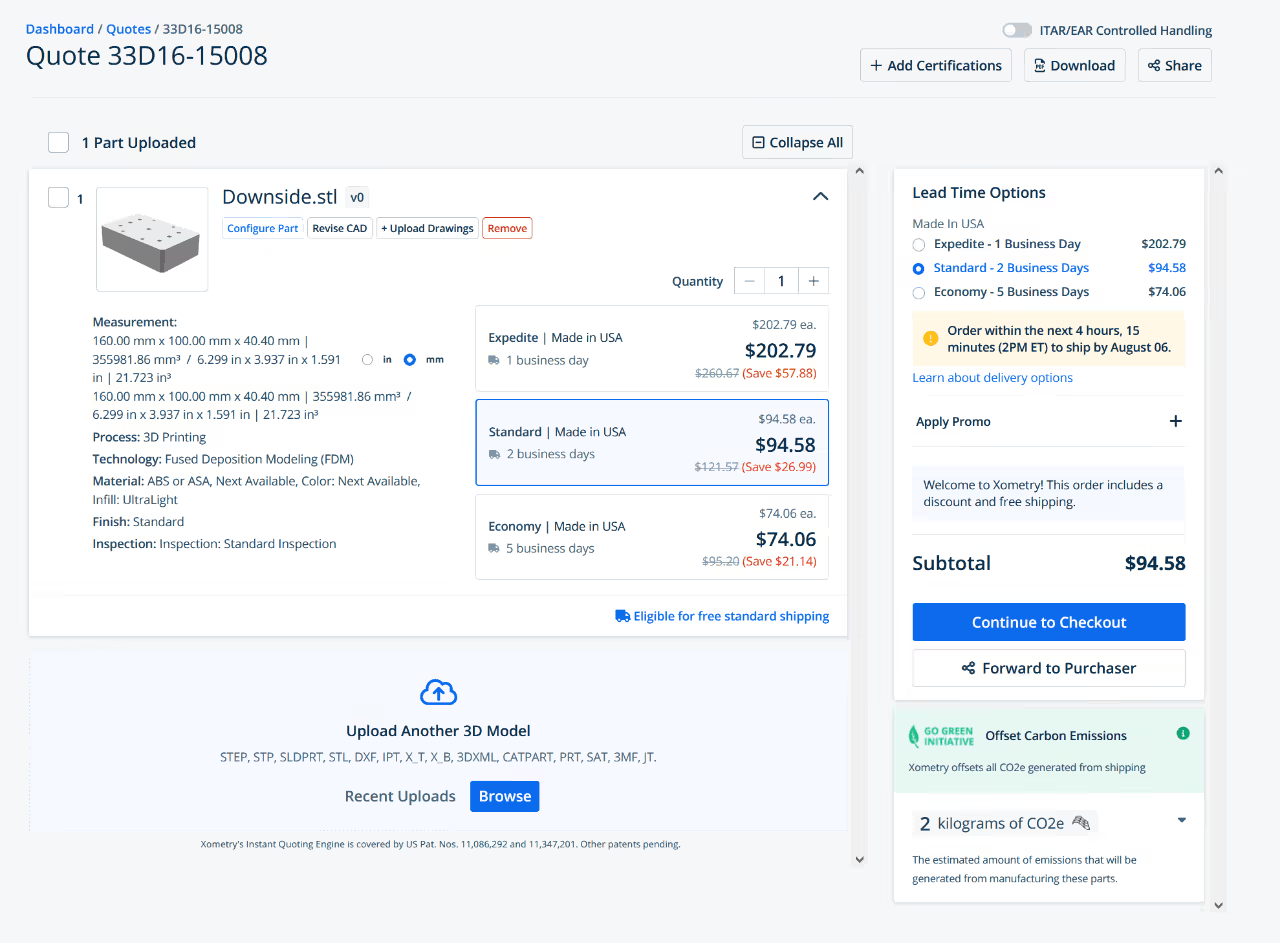

Assign to an online manufacturer: Consider services like Xometry for manufacturing needs. They offer quality production with various materials, including resin.

Visit Xometry: Xometry Website

-

-

Resin vs. Aluminum Moulds

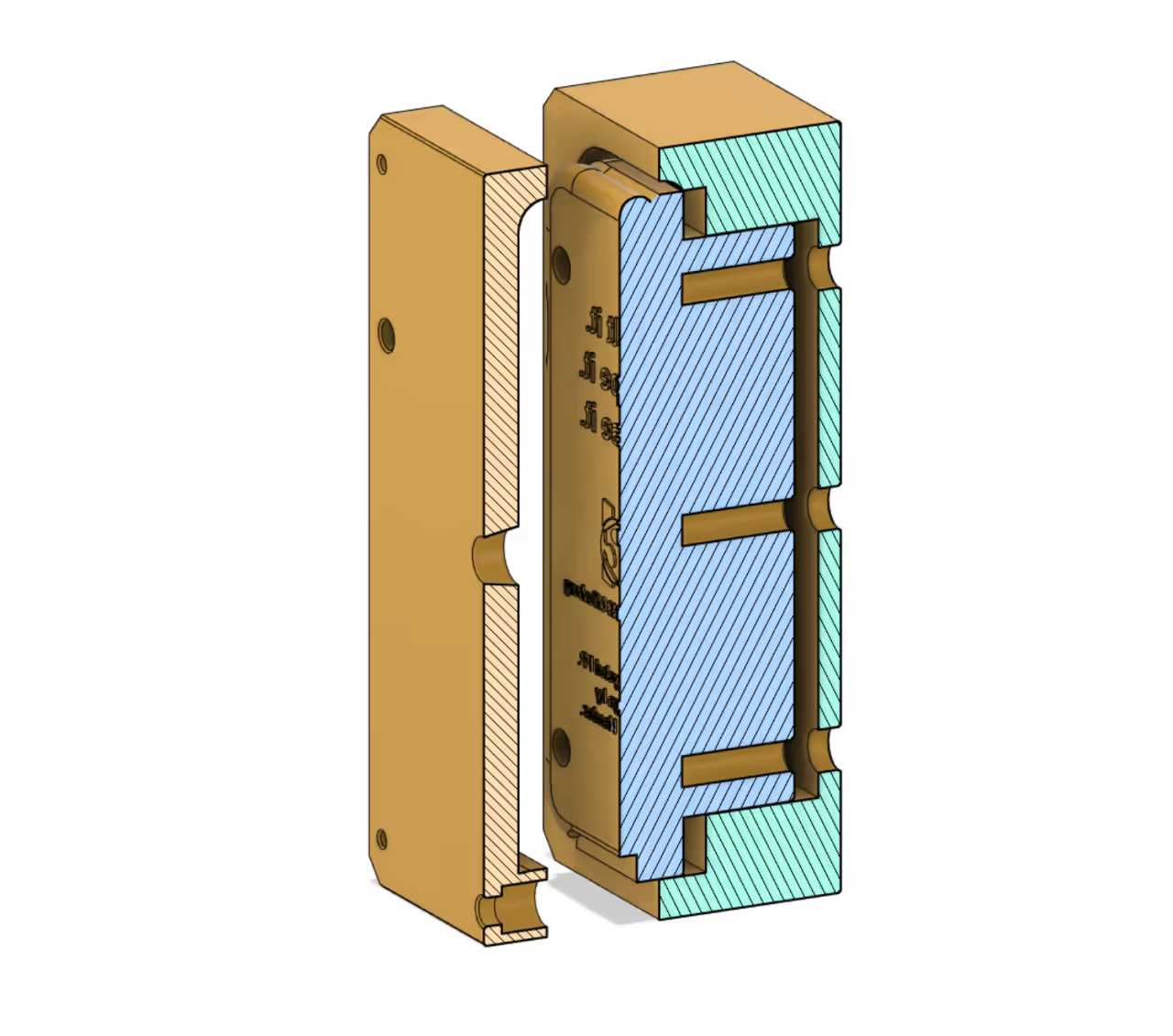

Resin differs significantly from aluminum, particularly in thermal conductivity, impacting heating, cooling, and moulding quality.

Resin conducts heat poorly, allowing for thinner wall designs but resulting in longer cooling times. Despite this, resin's slower cooling can reduce tension, minimizing cracking or warping risks.

However, resin is more brittle than aluminum, necessitating careful handling. Resin moulds are more susceptible to damage from abrasion or impact and may need more frequent maintenance or replacement.

-

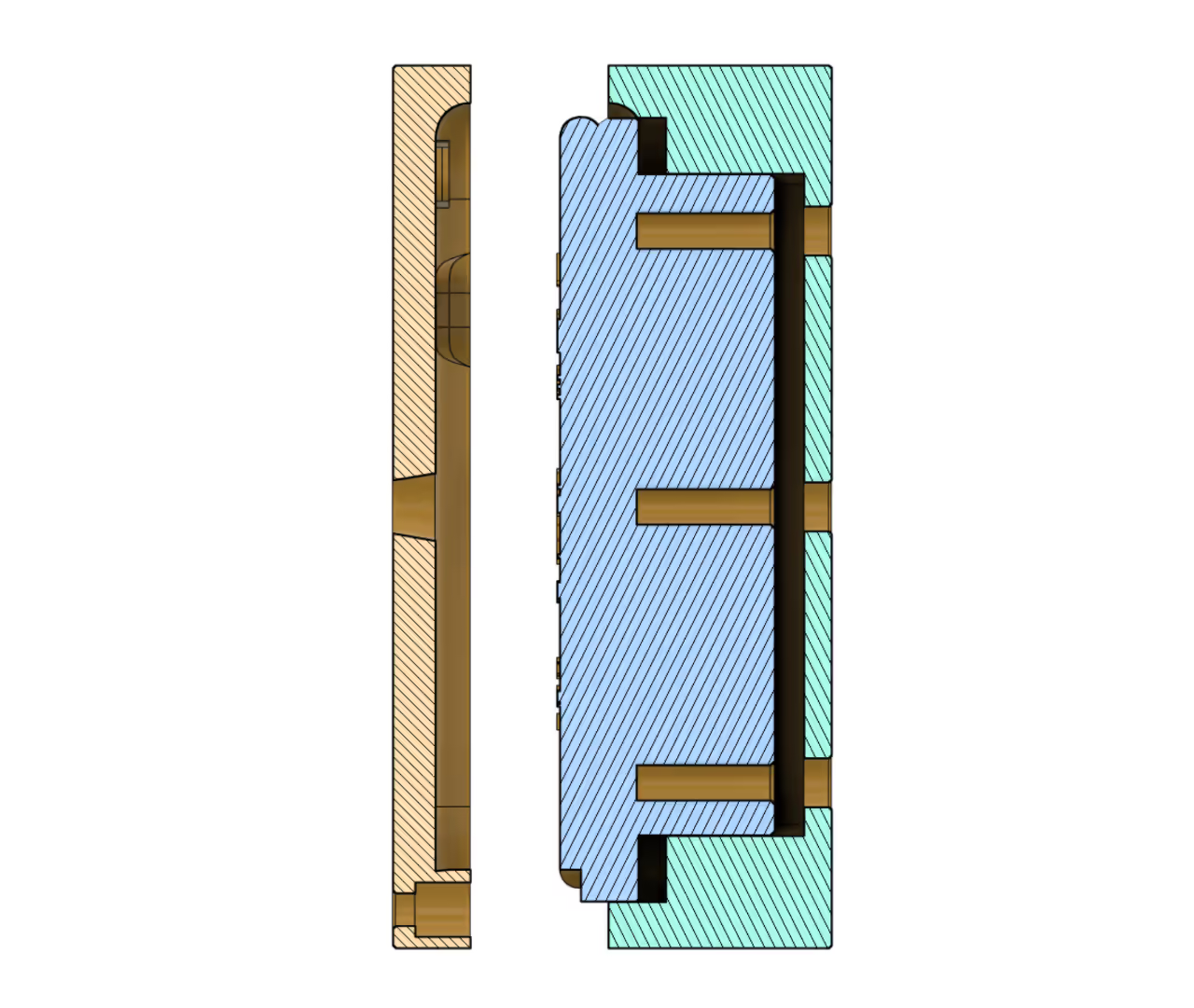

I designed a resin mold specifically for an automatic injection molding machine, which is my primary project. This fully automated machine utilizes ejector pins to remove the finished parts. Consequently, the mold's insert carries four holes for these pins.

To see the ejector mechanism in action, view the demonstration on my YouTube channel.

I trust this tutorial assists you. For more details on this mold or similar projects, such as the automatic machine, visit my channel.

Instagram: instagram.com/sotop_recycling

Sincerely,

Manuel

Software

- Fusion 360 (3D design with educational license option)

- ChiTuBox (slicing software for resin prints)

Hardware

- SLA resin printer (e.g., Elegoo Mars, Formlabs)

- High-temperature resin (e.g., Siraya Tech Blu, Phrozen TR250)

Resources & Services

- GrabCAD Library (download phone 3D models in STEP format)

- Xometry (outsource resin mold printing)

Supplementary Tools

- Automatic injection molding machine (for ejector pin integration) demonstrated here

- Ejector pins (for mold ejection mechanism)