Drying Granulate for Extrusion

For advanced materials, such as industrial waste, drying granulate is essential before extrusion. This step is crucial for producing high-quality products like 3D printing filament.

For a detailed guide, refer to our video:

How-To Video

Table of Contents

-

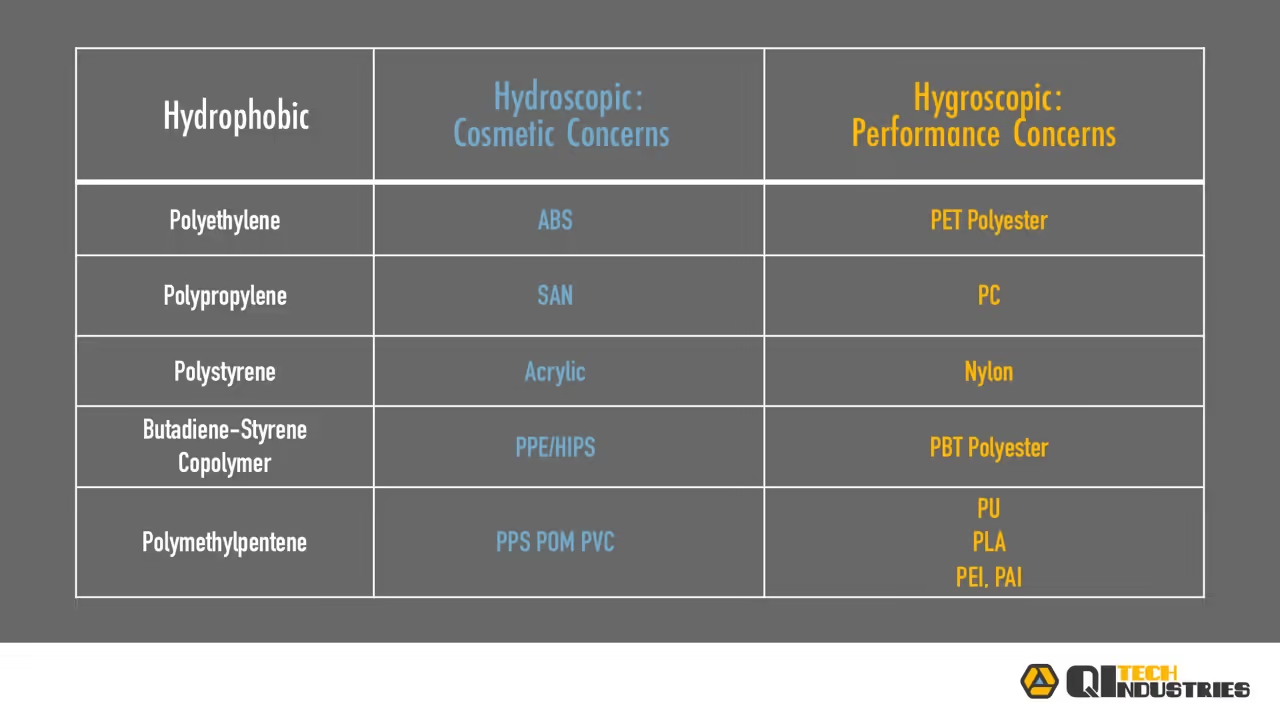

Types of Polymers and Moisture Considerations

Polymers are classified as polar or nonpolar. Nonpolar materials, like HDPE and PP, typically do not require drying, as they repel water similarly to oil. In contrast, many commercial polymers with polar characteristics can absorb moisture from the air. Drying is often essential to prevent cosmetic defects, such as splay or silver streaking, and to maintain material integrity. Polar polymers may undergo hydrolysis if processed with excess moisture, reducing their strength. For more details, refer to the material overview below.

-

DIY Polymer Drying Methods

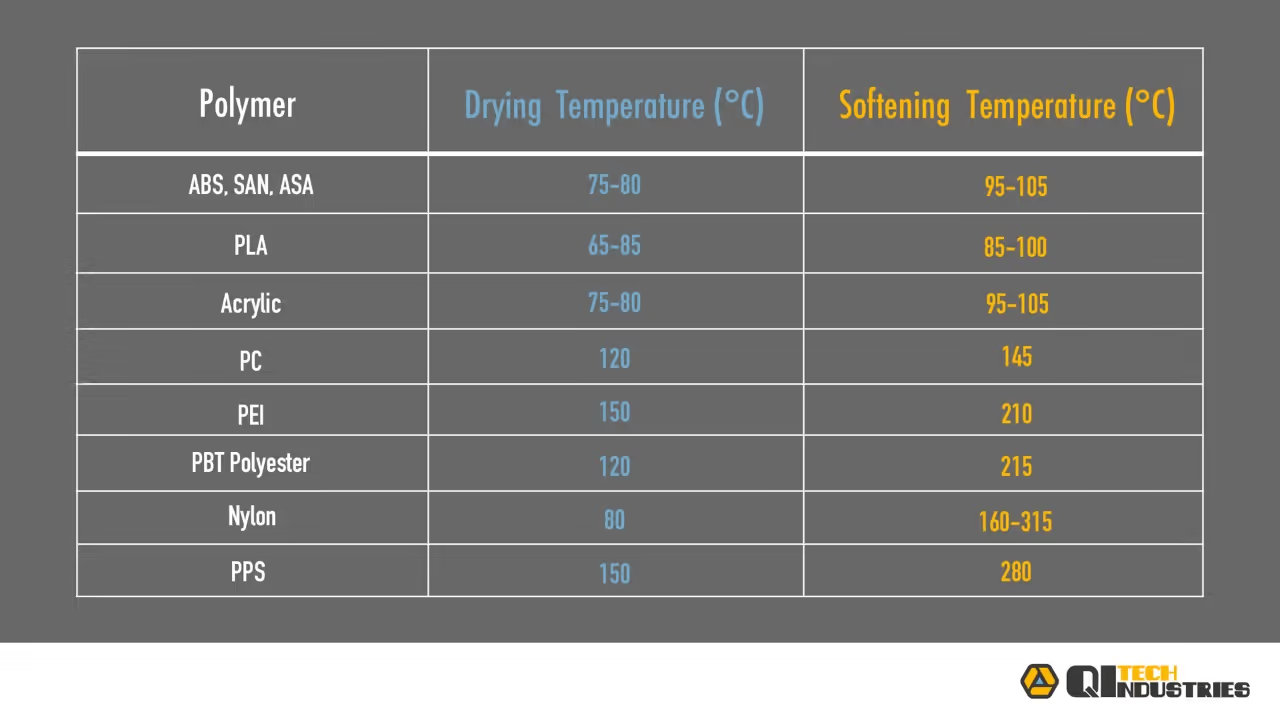

Several DIY methods exist for drying polymers, including an oven, dehydrator, or vacuum dryer. Here, we focus on constructing a dry box with silica gel, as it offers optimal results while being cost-effective, simple, and energy-efficient. Using an oven can lead to overheating, causing issues. Household dehydrators are not suitable for reaching the low humidity levels necessary for effective polymer drying. Below is a temperature guide for different polymers.

- Oven: Prone to overheating polymers.

- Dehydrator: Inadequate for low humidity requirements.

- Vacuum Dryer: Effective but more complex than a dry box.

Temperature Guide (for reference):

- [Include a table with temperature values for various polymers, converted from metric to imperial or vice versa where necessary.]

-

To create our drybox, use a plastic container and enhance it with window seals to ensure it is airtight. Glue the seals to the rim of the container.

-

You might recognize silica gel from shoe packaging. These small bags absorb moisture to keep items dry. Silica gel is also effective with polymers. Place about 2 kilograms (4.4 pounds) in the plastic box. While there is no exact required amount, more gel means less frequent drying is needed.

-

To monitor humidity within the drybox, a hygrometer is useful. A transparent box allows for continuous observation of the drying process.

-

Using a microplastic bag (e.g., one from Guppyfriend) inside the drybox conserves time and space by containing the materials while allowing humidity to escape.

-

The simplest way to measure moisture absorption is by weighing the granulate before and after drying. However, using hot air releases volatiles, which decreases weight but not accurately reflects moisture loss. Accurate moisture measurements require sensors placed in the drying hopper, which use real-time dielectric property measurements; however, these sensors are costly.

-

After some time, silica gel will reach its maximum water absorption capacity. Place it in the oven at 100°C (212°F) for one to two hours to restore its effectiveness.

-

Rapid temperature changes cause surface moisture. For example, when a cold drink is outside in hot weather, condensation forms. The same occurs with polymers. Moving plastic from a cold, damp garage to a warm production area led to surface moisture, causing bubbles and inconsistencies in our 3D-printing filament.

Tools

- Hygrometer (monitor humidity levels in drybox)

- Weighing scale (measure granulate weight pre/post drying)

- Oven (reactivate silica gel at 100°C/212°F [1])

Software

No specific software required.

Hardware

- Dry box (construction guide: plastic container + window seals) [1]

- Silica gel (2 kg, reusable after baking) [1][2]

- Airtight plastic container (modified with window seals) [1]

- Microplastic bags (e.g., Guppyfriend brand) [1]

- Heating source (oven for silica reactivation) [1]

Articles

Books

Papers

- Moisture Effects in Common Solderable RF Connector Dielectrics

- Real-time Monitoring of Drying Extruded Granules in Fluid-bed Dryer

- PET Extrusion Coating

YouTube

- Ultimate Dry Box for 3D Printer Filament

- DIY 3D Printing Filament Dry Box

- Simple 3D Printer Filament Dry Box