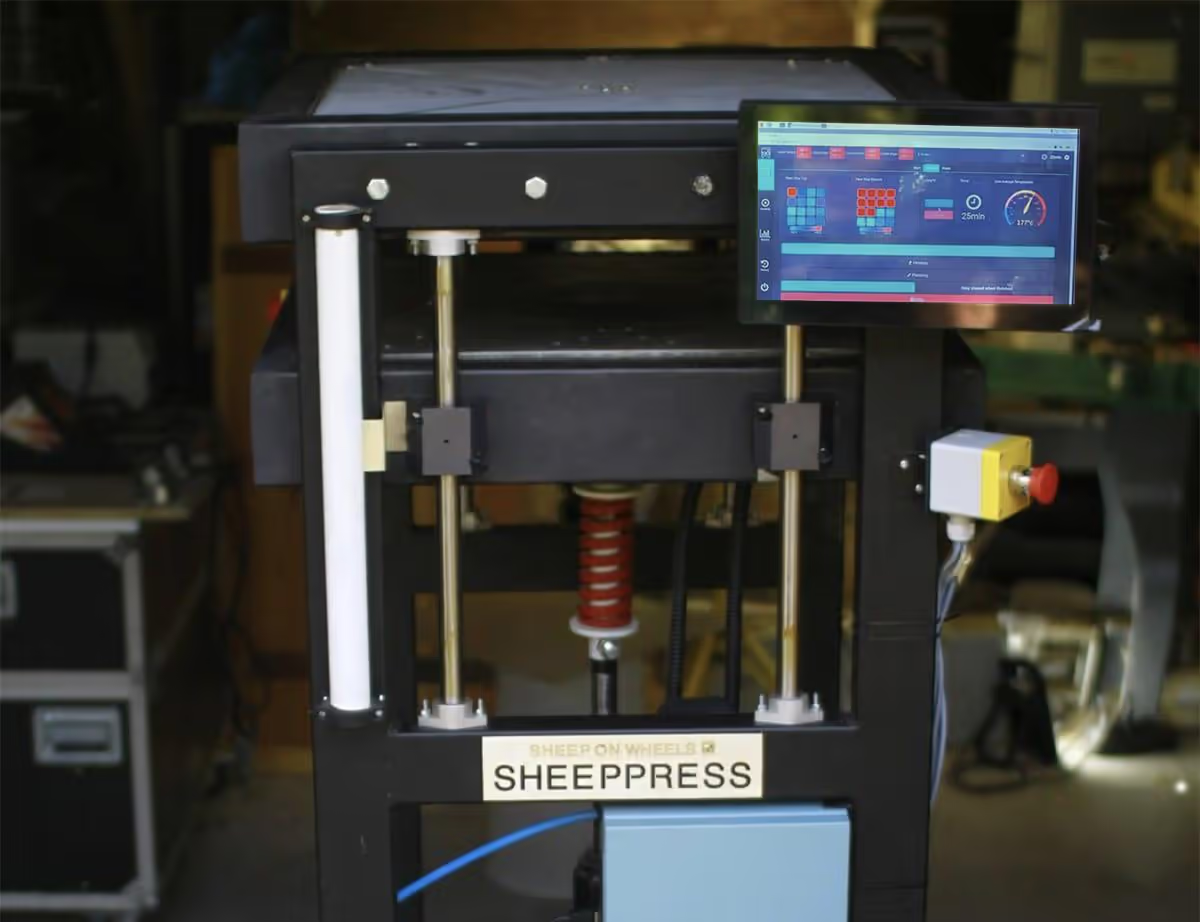

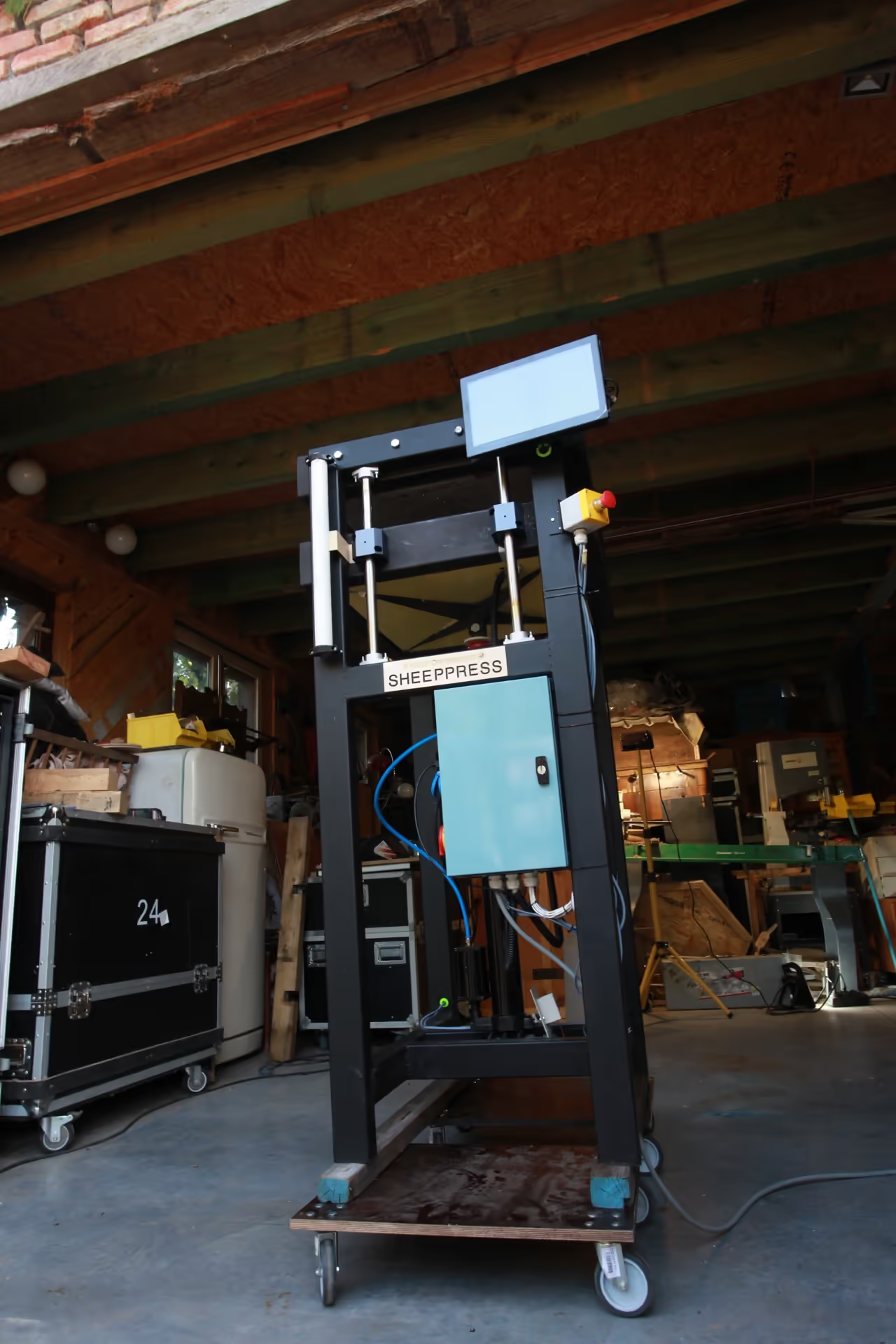

This document outlines modifications made to the sheetpress, aiming for automation and reduced time investment. The pressing surface measures 600x600mm (approximately 23.6x23.6 inches), designed for portability and compatibility with standard single-phase 230V (110V) power. For further information, please reach out to us.

Table of Contents

-

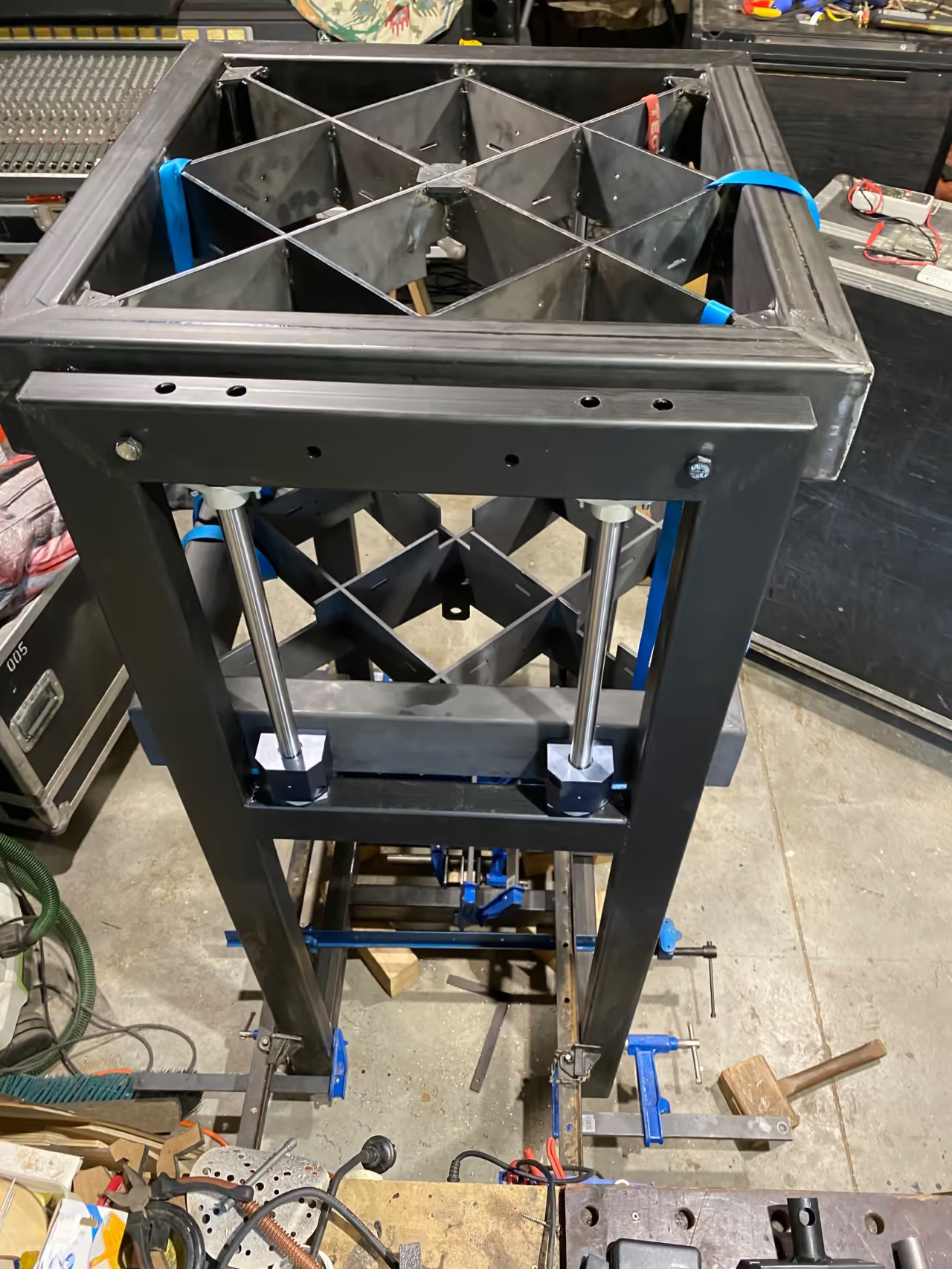

The foundation is based on the V4 sheet press, maintaining the same press and cartridge heaters but featuring a reduced steel frame with a pressing surface of 23.6 x 23.6 in (600 x 600 mm). We upgraded the bearings for a smoother fit.

-

We designed each heated plate with two distinct loops: an inner loop containing five cartridge heaters and an outer loop with four. The inner loop is expected to retain heat better and will therefore cycle off more frequently. We built a smaller version to facilitate use in mobile workspaces, operating at 230V to enhance compatibility with most power outlets.

-

We added multiple type K sensors (eight on each heating plate) to create an accurate heat map, allowing us to identify issues such as overheating or broken heaters. These sensors enable monitoring of core and peripheral temperatures, including warming and cooling speeds and fluctuations. The sensors are evenly distributed and not linked to specific heaters. Usage of this data will be explained in a subsequent step.

-

We replaced the original hardware PID controllers with a software version on the machine controller. This change enables further automation, data logging, and smoother integration into the user interface. It also allows us to monitor pressing times and maximum temperatures for optimized machine usage.

-

Currently, the thermocouples connect to a differential ADC designed for Raspberry Pi by AB Electronics. To enhance sensor performance, these will be replaced with a MAX31855, an integrated circuit by Maxim Integrated for type-K thermocouples. The heating elements are divided into four circuits—two per plate, with one outer and one inner circuit. Each circuit is controlled by the Raspberry Pi via a solid-state relay. These relays switch 230V AC and can be controlled with a 4V-48V signal. To safeguard the Pi from 230V AC short circuits, the relay drive signals are optically isolated.

-

The digital interface operates on a Raspberry Pi connected to a touch screen. It comprises a server and a client side. The client side is a website accessible from the Pi’s browser or any device connected to the Raspberry Pi's Wi-Fi. The server is built using Node.js.

-

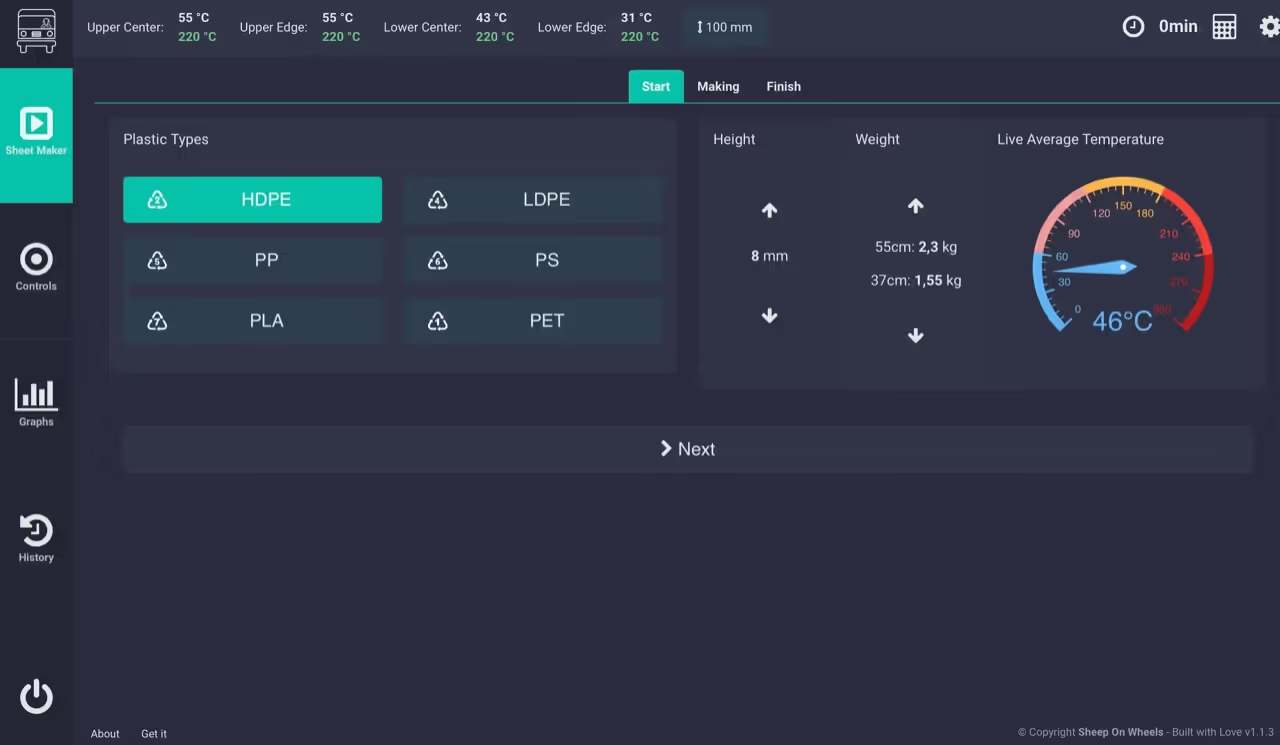

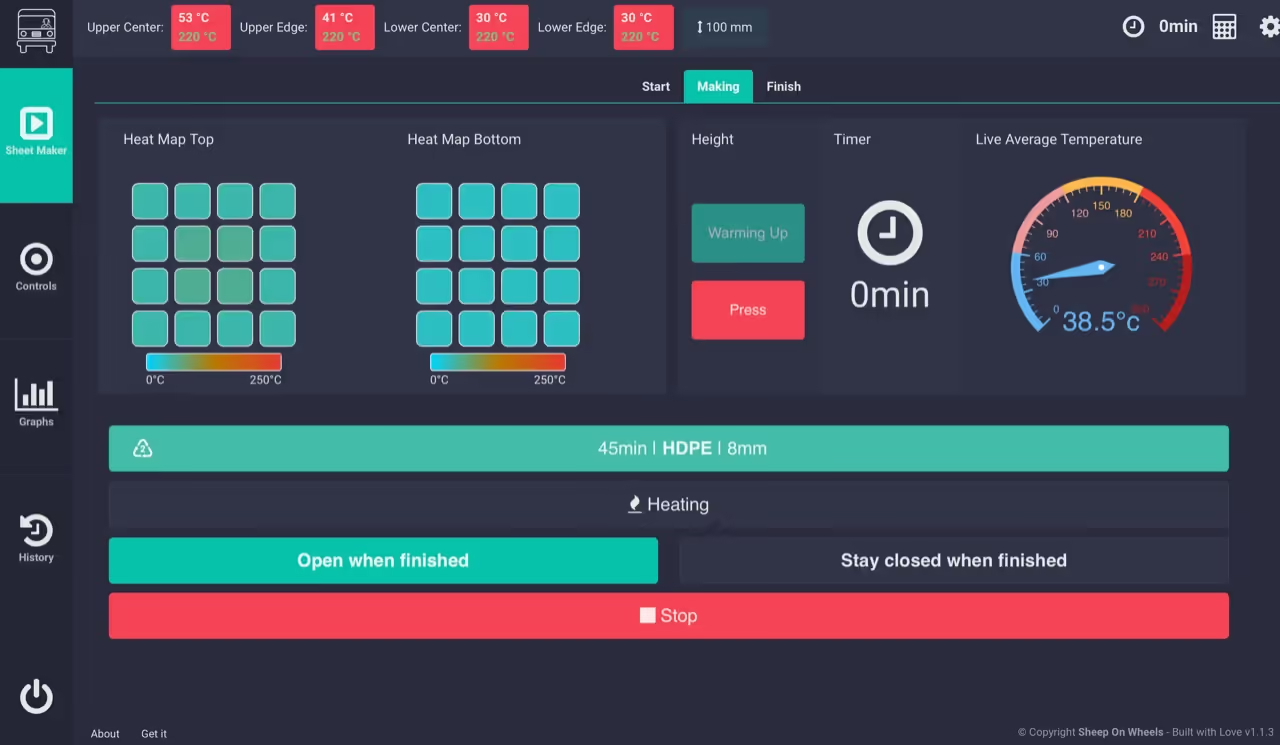

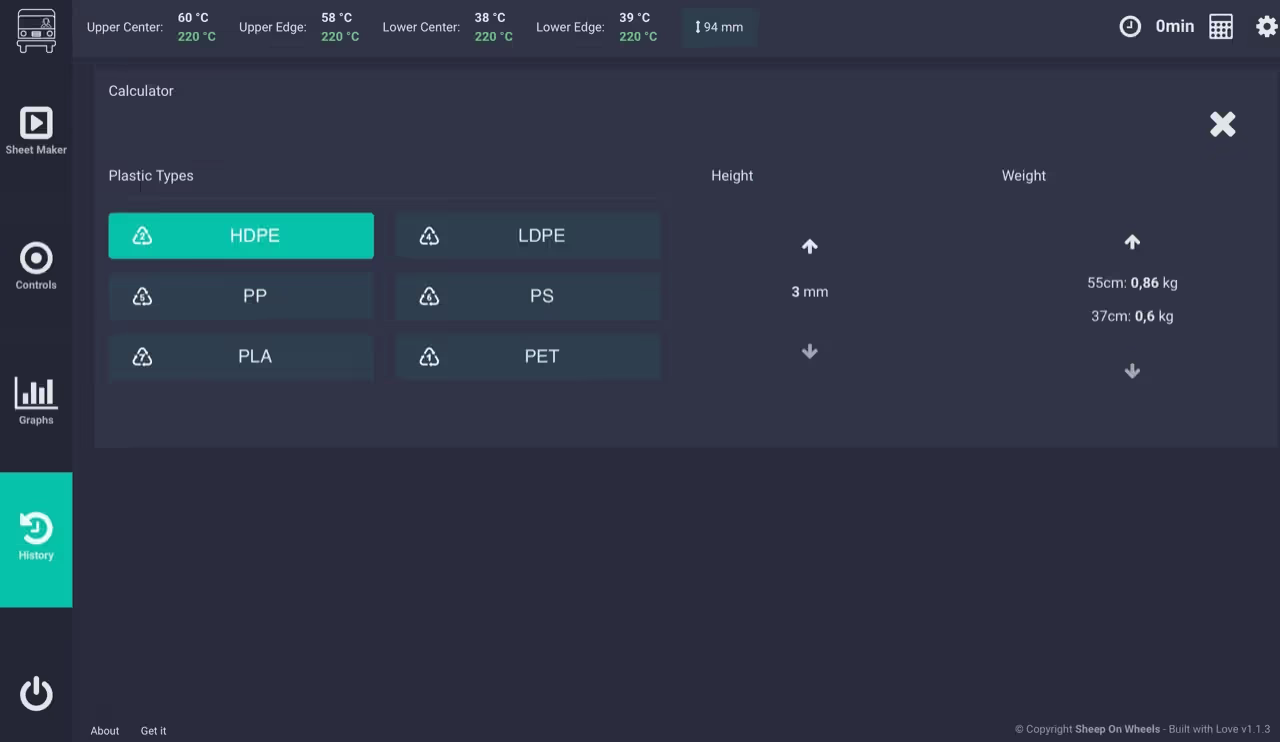

- The sheet maker page enables users to create an automated sheet, allowing selection of plastic type and desired sheet thickness. Metal frames determine thickness and sheet size/shape. The system calculates the necessary weight for production and displays the required time and temperature.

- Next, initiate the heating process while setting up the sheet on the prep table. The system adjusts to the appropriate temperature for each plastic type automatically.

-

- Once the plates reach the desired temperature, insert the prep sheet and select the press function. This initiates automated pressing and activates the timer. Periodically, the system will maintain pressure with an alert sound as a warning.

- During pressing, choose options for subsequent steps: either automatic opening to 4 inches (10 cm) when the timer ends or remain closed. In both scenarios, heating will cease.

- An alert sound signals the timer's completion.

-

- Upon completion, you may replicate the process or restart.

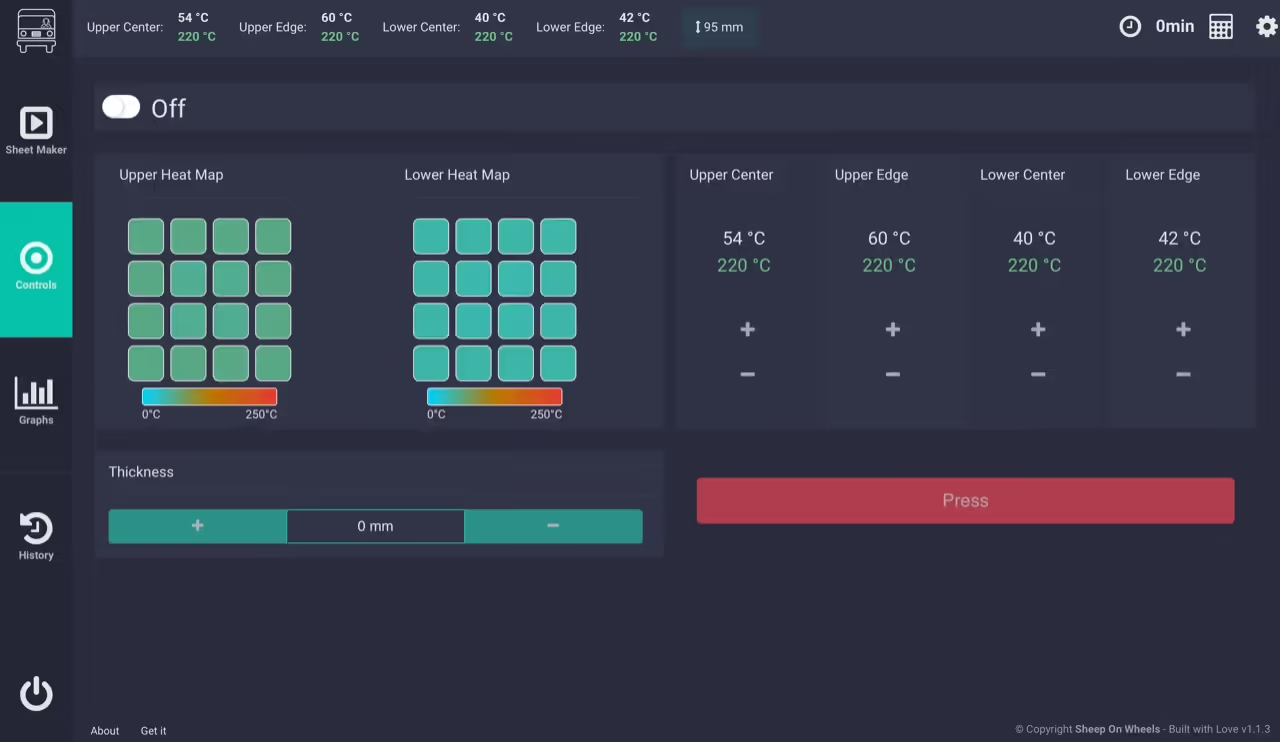

- These steps may be manually controlled on the controls page. Each of the four heating circuits can be adjusted for temperature and to open or close the press. Manual controls are not available when the sheet maker is operating automatically.

- Two heating maps for each plate are available on the graphs page, enabling users to monitor each heating element. Additionally, there are two graphs: one showing the average temperature over the last 15 minutes and another displaying the last 2 hours.

-

-

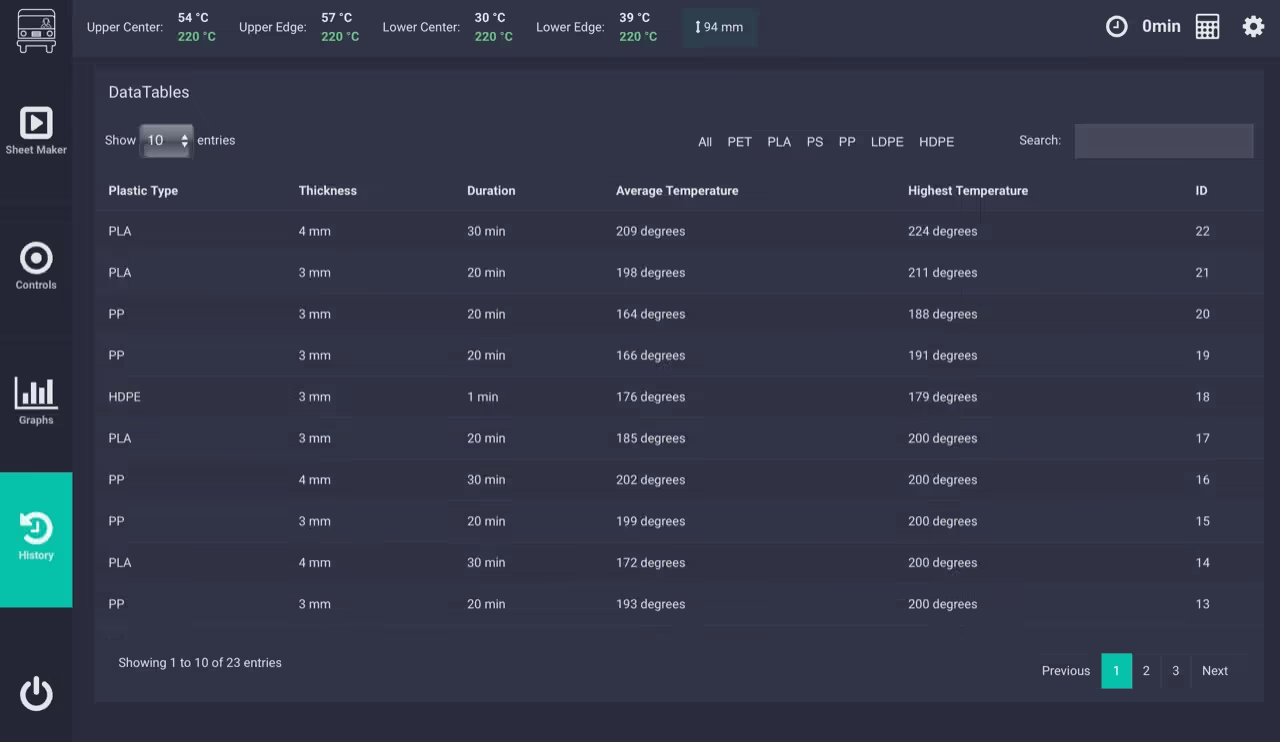

The history tab displays all sheets produced using the automated process, including their ID numbers, average and highest temperatures, plastic types, and pressing durations.

-

The calculator function enables preparation of the next sheet while the machine is in operation.

-

-

We utilize pneumatics to operate the jack due to the availability of an air compressor, making it the cost-effective option. Alternatives include hydraulic systems. A pneumatic valve, controlled by the system controller, allows air to flow when the press is to be raised. To lower the press, we installed a servo to open or close the valve, letting the press descend under its own weight.

Upon timer expiration (sheetmaker), a signal from the Raspberry Pi prompts the Arduino to release the press, with manual override possible if necessary.

-

A sensor is attached to the upper plate to measure the distance to a reflector on the lower plate. The casing, a sliced PVC tube, limits interference. This measurement is sent to the Arduino, allowing the machine to determine the plates' positions and manage air flow. The sensor used is a Time of Flight Sensor VL6180.

Tools

- Sheetpress with 600x600mm heated plates and upgraded bearings ~~🔗~~

- Cartridge heaters (5 inner/4 outer per plate) ~~🔗~~

- 16 type-K thermocouples (8 per plate) for heat mapping ~~🔗~~

- Pneumatic valve system with air compressor and servo control ~~🔗~~

- Custom metal thickness/size frames

Hardware

- Raspberry Pi with touchscreen interface ~~🔗~~

- MAX31855 thermocouple interface (replaces AB Electronics ADC) 🔗

- Solid-state relays (230V AC, 4V–48V DC control) ~~🔗~~

- VL6180 Time-of-Flight distance sensor 🔗

- Arduino Nano for pneumatic valve control 🔗

Software

- Node.js server backend 🔗

- Web-based client interface (local network)

- Custom PID controller software for temperature regulation

- Automated sheet production calculator with material/thickness presets

- Real-time graphing (15-minute/2-hour temperature history)

Here are the references grouped by type based on the search results provided:

Articles

- Automate Offset Press Process Control | Using X-Rite Solutions

- Advanced ex-press sheet management for improved quality and productivity

- Sheetfed Offset Printing Press Automation Advancements

- Printing Industry Automation & Control Systems

- ~~Product Spotlight: Canon Press Automation Modules—Optimizing & Simplifying Printing~~

- Automation in Offset: Simplifying Production and Increasing Profitability