Creating Plastic Sheets (12 in x 10 in x 0.4 in)

Sharing this method may benefit others. Please share this information and acknowledge Zero Plastics Australia if you produce work from these sheets.

Table of Contents

-

Materials Required

-

Heat Press Machine: Purchase a 38cm x 38cm (15in x 15in) model.

-

Aluminium Sheets:

- Two sheets, each 40cm x 40cm (15.7in x 15.7in), 3mm-5mm (0.12in-0.2in) thick.

-

Aluminium Mold:

- One mold, measuring 30cm x 25cm x 1cm (11.8in x 9.8in x 0.4in) internally.

Note: Avoid exceeding a 33cm (13in) internal size for the mold, as larger dimensions may lead to incomplete melting at the edges.

-

-

Instructions for Making Plastic Sheets

- Place one aluminum sheet (aluminium) on the heat press.

- Position the mold on the aluminum sheet.

- Fill the mold with 28 ounces (800 grams) of HDPE shredded plastic.

- Cover with the second aluminum sheet.

Apply mold release to the sheets and mold if available.

-

- Set your machine to 392°F (200°C) and allow it to reach maximum temperature.

- Set the timer for 16 minutes (960 seconds).

Adjust the machine and mold height accordingly. Cook the mold for 16 minutes, tighten, and repeat three times.

- Upon reaching maximum temperature, close the lid securely. It may take several attempts to close tightly without spillage.

-

Once the lid is closed on the mold, the timer starts with 16 minutes for the initial process of making a sheet. After the first 16 minutes, open the machine and tighten it.

- Tighten the machine (usually 3 full turns suffice, but adjust as needed).

- Close the machine and cook for another 16 minutes.

- Upon completion, flip the mold (as the machine heats from one side). Flipping it front to back yields optimal results.

- Cook for two additional periods (16 minutes each).

In total, cook the mold four times (twice on each side).

-

Once the final cooking is finished, place your mold with the hot side down on a cool concrete surface. This is crucial to prevent warping.

- Position the hot side on the ground.

- Apply weight on top of the mold, using as much as possible.

-

Instructions for Sheet Mold Cooling and Removal

-

Cooling Time: Allow the mold to cool for approximately 30 minutes. If feasible, extend this duration for optimal results.

-

Removing the Sheet: After cooling, open the mold. Use a utility knife to cut the sheet if no mold release agent was applied.

-

Additional Cooling: If the sheet remains hot, turn it over and place a weight on top for another 30 minutes.

-

Completion: Your sheet is now complete.

-

- 7FAQs

You might have additional questions since this is a complex process, but it becomes straightforward and requires minimal labor once mastered.

- How do you adjust the machine's height? Refer to the manual provided with the heat press; it involves a screw at the machine's top.

- Can different plastics be used? Yes, although I only use HDPE. Please share runtime and temperature if using other types.

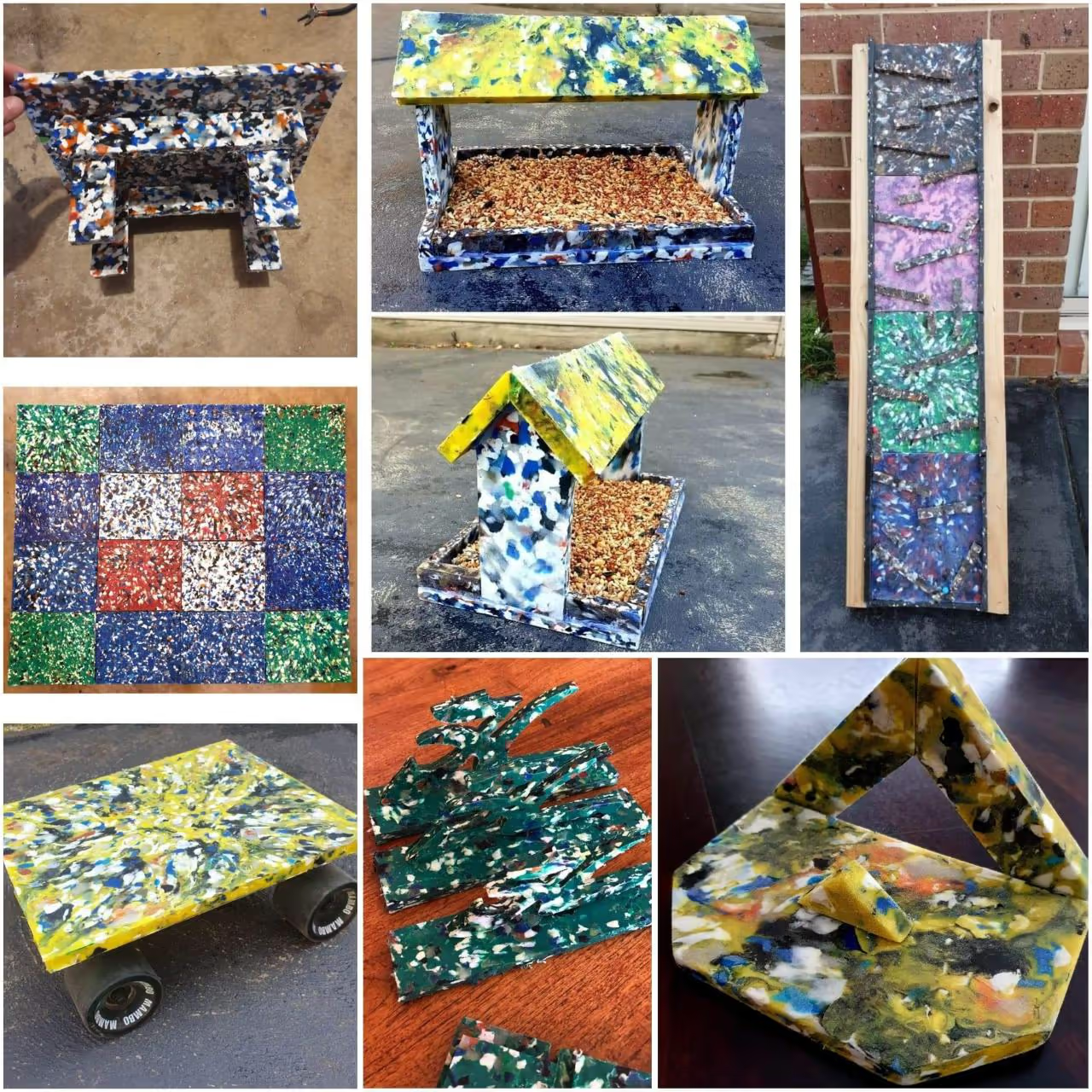

- What are these sheets used for? Consult attached photos or our social pages for updates.

For further inquiries, email zero.plastics.australia@gmail.com.

Tools

- Utility knife (for cutting plastic sheets)

- Mold release applicator (optional)

Software

- Not required

Hardware

- Heat press machine (38cm x 38cm / 15in x 15in)

- 2x Aluminium sheets (40cm x 40cm, 3-5mm thick)

- Aluminium mold (30cm x 25cm x 1cm internal)

- Heavy weights (for cooling, e.g., concrete blocks)

- Adjustable screw mechanism (integrated into heat press)

Contact ~~Zero Plastics Australia~~ for process-specific guidance.

Articles

- https://en.wikipedia.org/wiki/High-density_polyethylene

- https://www.beeplastic.com/blogs/plastic-insights/the-ultimate-material-showdown-hdpe-sheets-vs-other-plastics

- http://www.grafixplastics.com/materials-plastic-film-plastic-sheets/commodity-plastic-film/polyolefin-sheet/hdpe-sheet/

- https://www.craftsuprint.com/projects/paper-craft/book-crafts/how-to-make-a-durable-plastic-book-cover.cfm

- https://simonwillison.net/dashboard/blogmarks-that-use-markdown/

- http://filefoldermachine.com/1-3-plastic-sheet-extrusion-line.html

Books

- https://excelitefab.com/e-book-complete-guide-polycarbonate-fabrication/

- https://download.e-bookshelf.de/download/0000/5853/75/L-G-0000585375-0002361409.pdf

Papers

- https://peer.asee.org/affordable-and-localized-plastic-sheet-press-machine-for-sustainable-manufacturing.pdf

YouTube

- https://www.youtube.com/watch?v=nQEvEjdvToQ

Open-source Designs

- https://www.instructables.com/Casting-with-Soft-Mold-Constructed-from-Sheet-Mate/

- https://www.[filtered].earth/news/sheetpress

GitHub Resources

- https://gist.github.com/chapmanjacobd/9a5d9eae393d059398b6b8b6369c0c71

- https://github.com/tatsu-lab/alpaca_eval/blob/main/results/gpt-3.5-turbo-1106/model_outputs.json

Other Resources

- https://huggingface.co/datasets/brando/small-open-web-math-dataset-v2/viewer