Today, volks.eco and PlastOK present a method to inject plastic parts using solar and human power. This approach aims to expand the concept of using plastic waste globally. Remember to protect yourself from the sun.

Table of Contents

-

You will need:

- Volks.eco solar concentrator

- Hydraulic jack press

- Plumbing pipe cartridge

- Shredded HDPE

- Injection mold

- Cup of water

- Oven gloves

- Clamp

Locate a sunny area and preheat the solar tube concentrator.

-

Insert shredded plastic into the iron cartridge.

Compress the necessary plastic based on your part's volume within the cartridge.

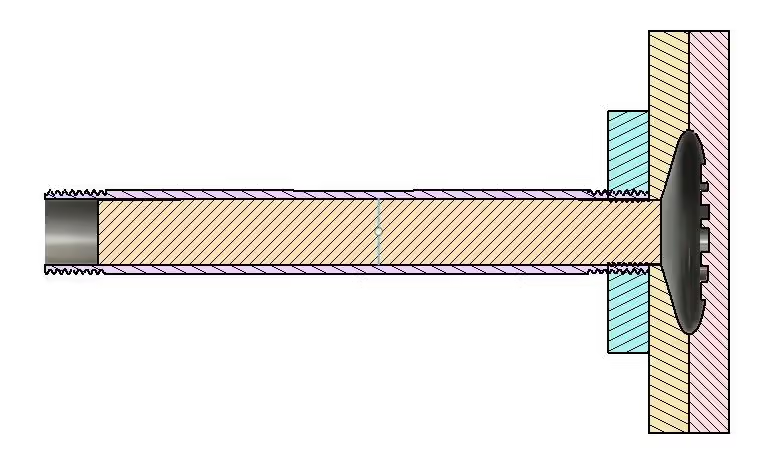

Secure the plumbing pipe with ½ inch (1.27 cm) cap ends.

Place the cartridge inside the solar concentrator.

-

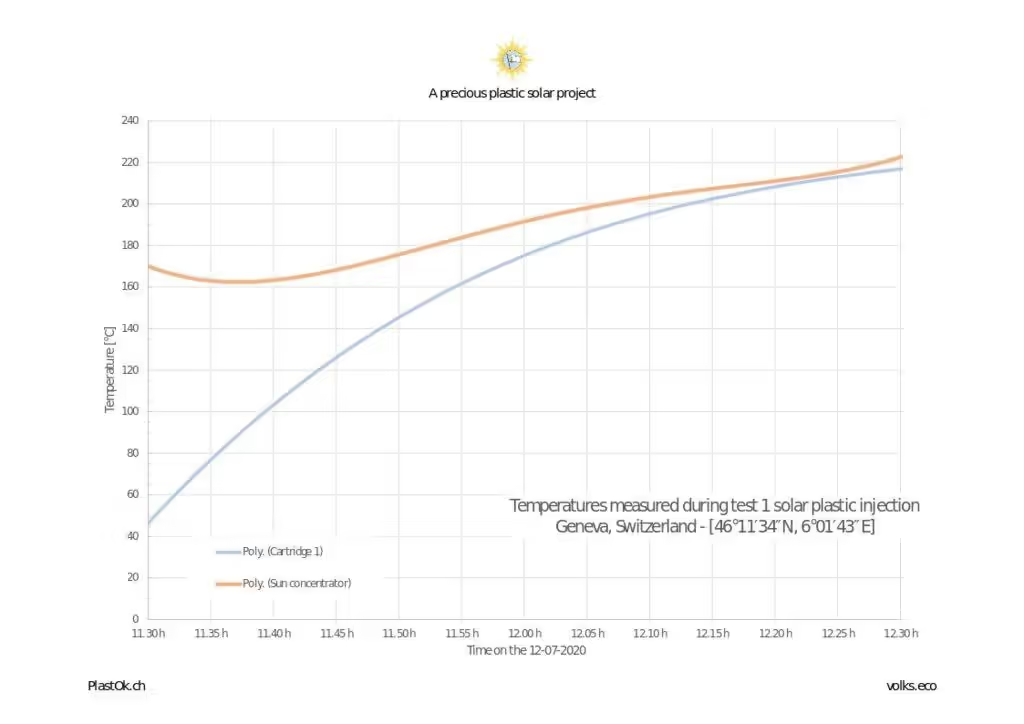

Allow 30 to 60 minutes depending on sunlight exposure. Multiple iron cartridges can be loaded in the solar concentrator to expedite the process. Monitor the cartridge temperature with a probe placed inside the heated tube. The concentrator can reach temperatures between 356°F and 482°F (180°C and 250°C). This method offers extensive learning opportunities.

-

The cartridge will be very hot; use gloves.

Remove the two cap ends from the hot cartridge.

Submerge one end of the tube in the cup of water.

By doing this, a solid plastic piece will form and push the melted plastic into the mold.

Note: Preheating the mold above 140°F (60°C) enhances the finish. This can be achieved by placing the mold in a solar concentrator for a few minutes.

-

Inject the plastic into the mold as quickly as possible for best results.

We will provide instructions on constructing a portable hydraulic jack press in the future.

-

Ensure the mold is cooled before removing the injected part; submerge in cold water if necessary.

You now have a completed part produced using manual and solar energy.

The mold requires mechanical enhancements for extraction as it is merely a prototype for this concept.

- 7Recap

This video outlines the complete process and expected duration of each step, with room for improvement.

The solar concentrator operates without electricity.

It can be set up anywhere (beach, mountain, city) in any season, requiring only sunlight.

For more information, visit volks.eco and contact Marco.

Marco has extensive experience with this solar concentrator, which has various applications.

Explore its potential for solar energy applications.

Thank you, Marco.

Tools

- Oven gloves (heat protection)

- Clamp (for securing components)

- Temperature probe (monitor cartridge heat)

- Water cup (cooling/forming plastic piece)

- Mold extraction enhancements (prototype stage)

Hardware

- ~~Volks.eco solar concentrator~~ (reaches 356°F–482°F / 180°C–250°C)

- Hydraulic jack press (manual/solar-powered)

- Plumbing pipe cartridge (½-inch capped ends)

- Shredded HDPE plastic (raw material)

- Injection mold (preheatable above 140°F / 60°C)

Software

N/A (process relies on manual/solar energy without software components)

Articles

- ~~Solar Plastic Molding | LightManufacturing Inc.~~

- Plastic Injection Moulding: The Silent Hero Transforming the Renewable Energy Sector

- Graded Index Lens as a Nontracking Solar Concentrator (AGILE)

Papers

- European research group creates injection molding plastic solar cells

- Injection Molding Plastic Solar Cells - PMC

Open Source Designs

- Sun Concentrator for Solar plastic melting

- Micro Injection Molding Machine - Hackaday.io

- Solar Plastic Injection : 7 Steps - Instructables