Mini Beads Mold Tutorial

Create diverse bead shapes simultaneously for jewelry making with this mini beads mold. Follow these steps to make your own!

Table of Contents

-

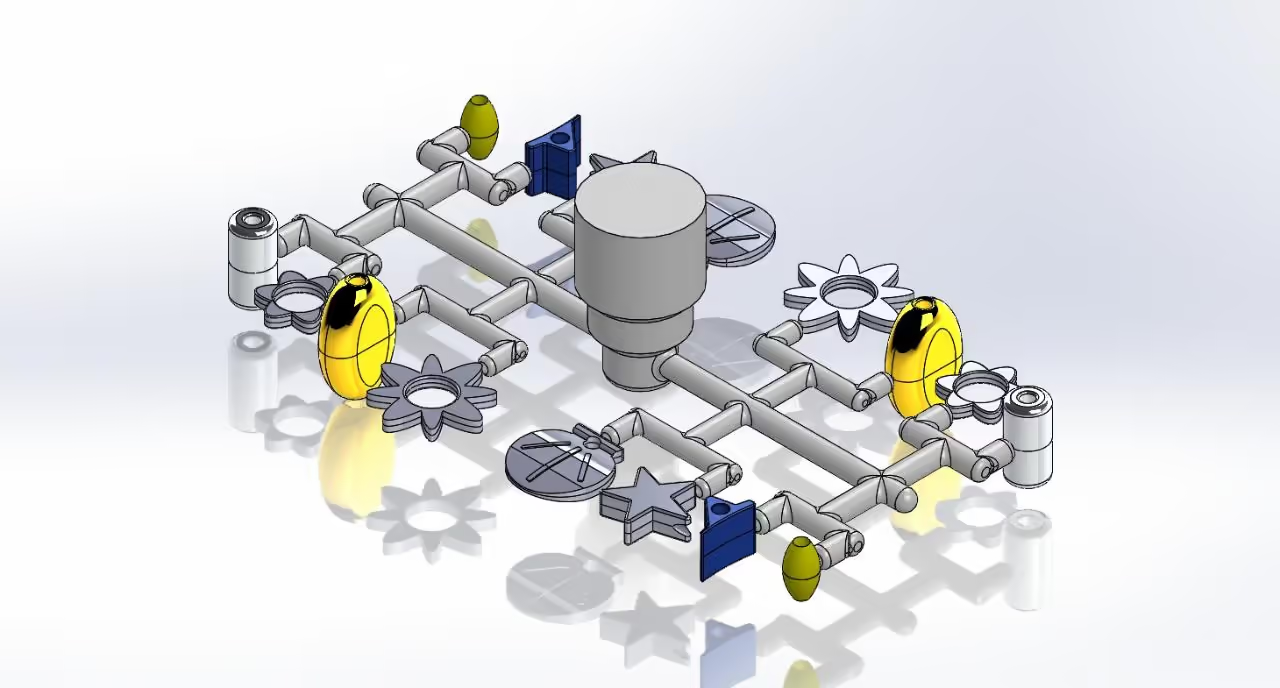

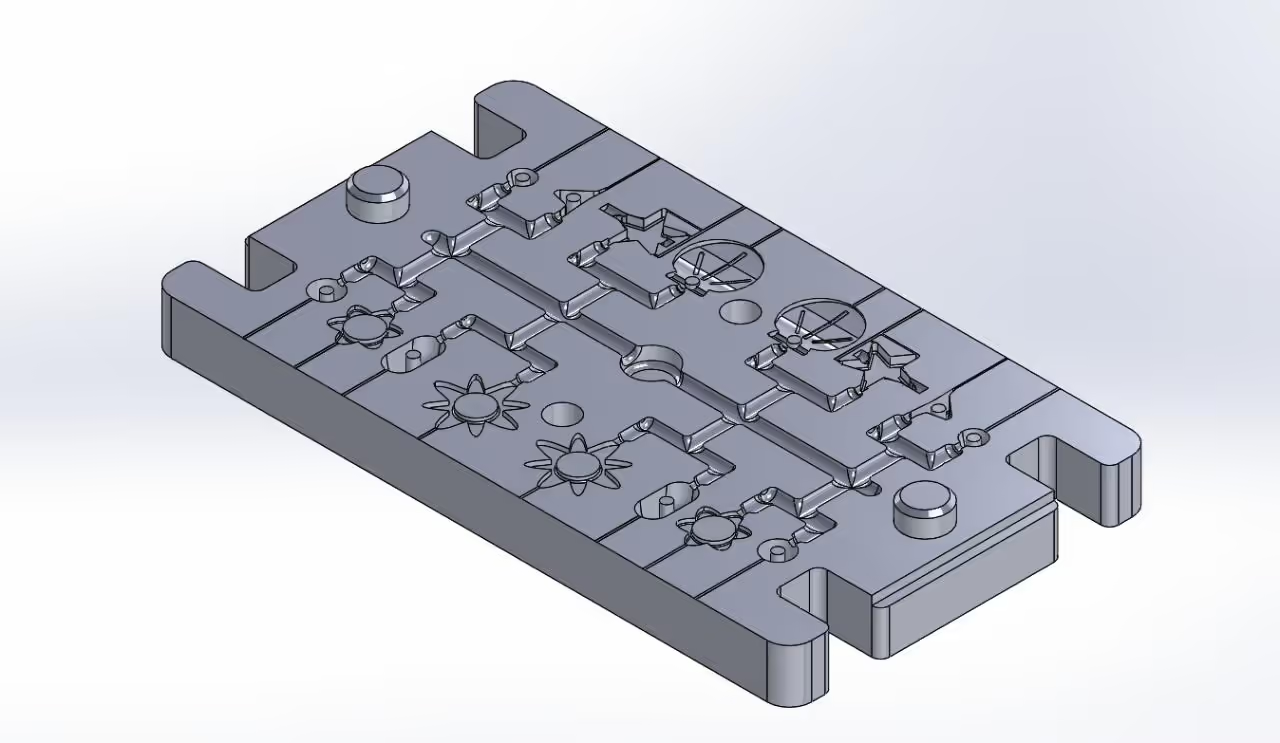

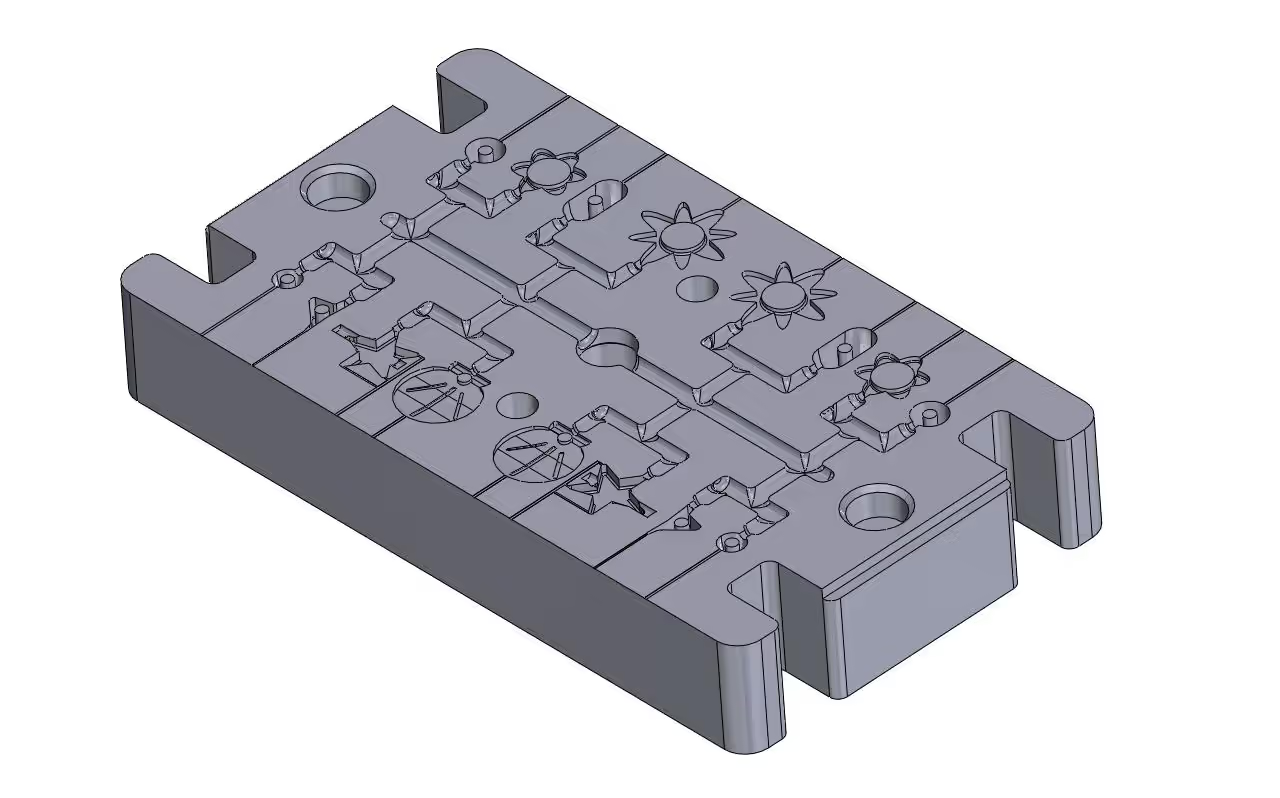

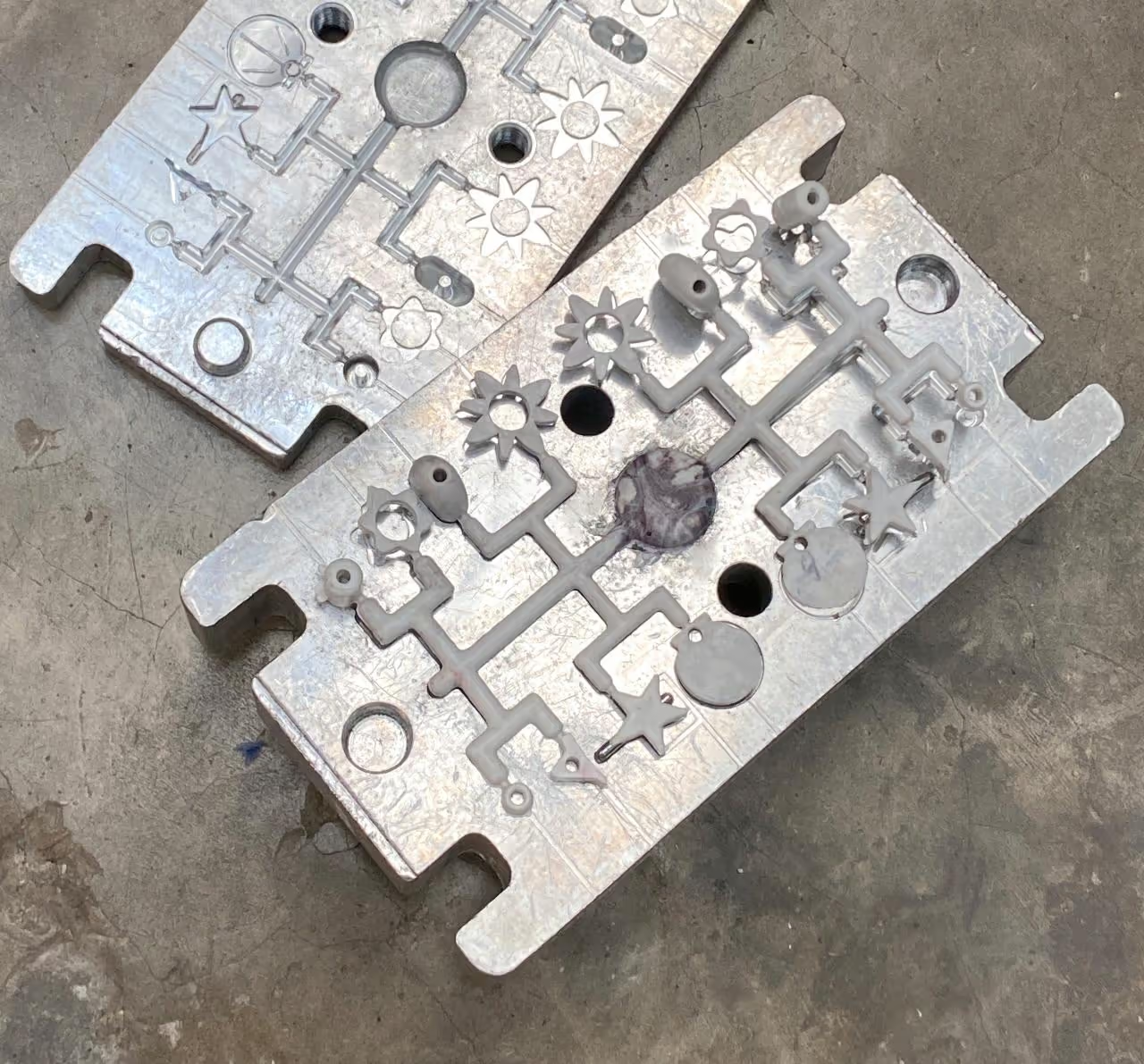

To create various bead sizes and shapes, a mould with balanced cavities is necessary. Design your desired shapes based on the types and sizes of cords you plan to use, ensuring the bead hole is approximately 3% larger than the cord. Align bead holes vertically with the mould's detachment line. All beads are bisected at their center except the star-shaped one, which requires a dowel pin for the hole, due to CNC machine limits when placed vertically.

-

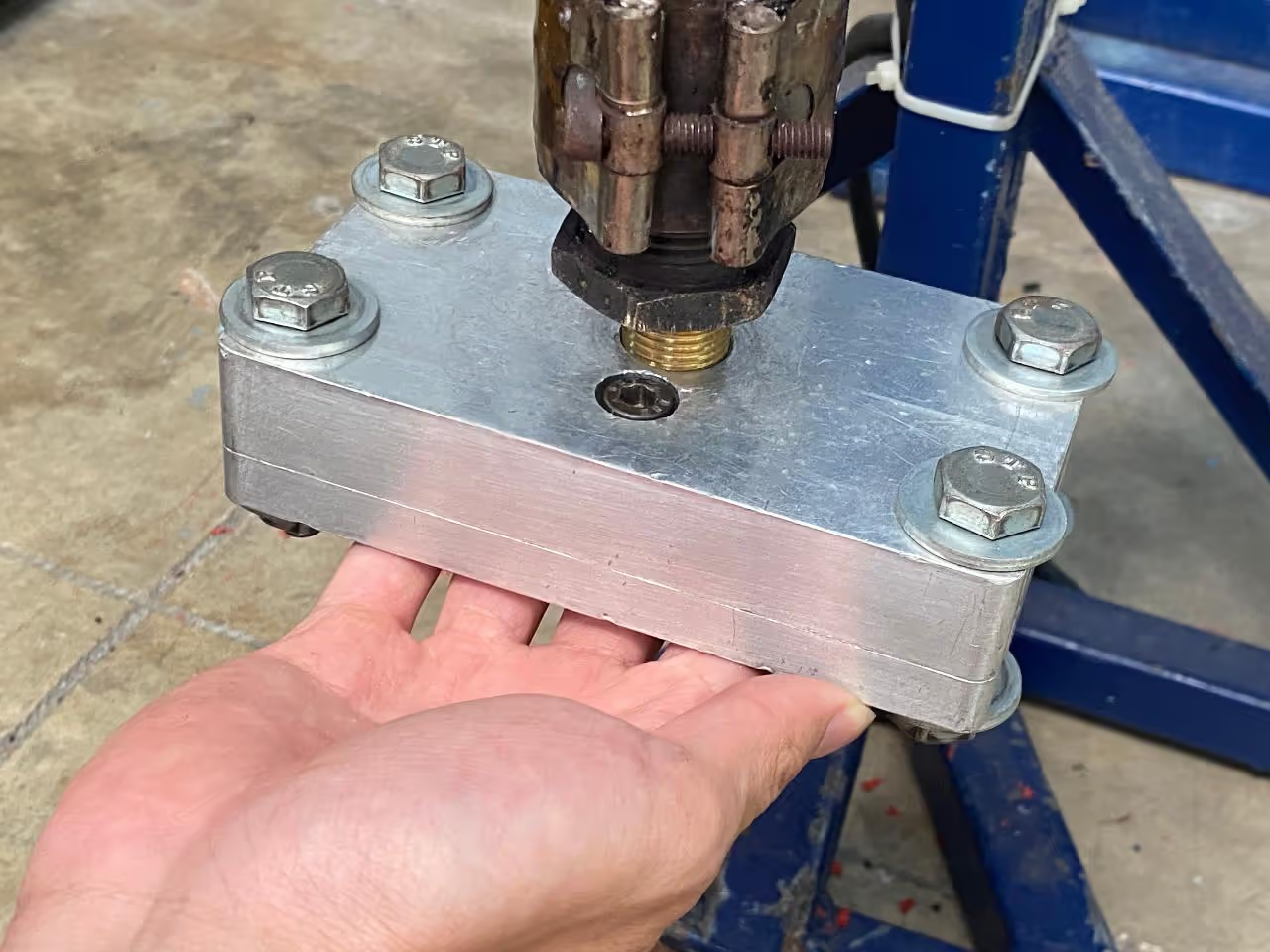

There are 16 bead cavities in the mold, with the quantity based on the barrel capacity. Adjust the bead count per mold to balance the plastic mass according to flow direction. The components are CNC-milled from two aluminum blocks, comprising three pieces: top and bottom aluminum parts, and a dowel pin for the star bead. The top part connects to a bronze nipple (1/2 inch NPT).

-

Tools needed: Gloves, Mask, 17 mm (0.67 in) Wrench, 4 mm (0.16 in) Allen Wrench

Machines needed: Injection Machine, Shredder (or Shredded Plastics)Ensure the mold is clean. Place the dowel pin in the star shape and align the top and bottom parts using the guide pin. Insert M10 bolts at the four corners and two counter-bore bolts in the center holes. Proceed with injection.

- 4Inject

Injection Molding Process

-

Prepare the Machine

- Place shredded plastic into the injection machine.

- Set the temperature to the appropriate melting point for your plastic type.

-

Heat and Inject

- Heat the machine, ensuring the handle remains down to apply pressure.

- Lift the handle and position your mold in the injector.

- Safety First: Wear a protective mask and gloves.

-

Inject the Plastic

- Pull down the handle forcefully to inject the melted plastic into the mold.

- Maintain pressure for approximately one minute, adjusting the time based on the plastic type used.

-

-

Lift the bar slightly and remove the mold. Ensure the injection is closed to prevent plastic from dripping. Unscrew all bolts and use a slotted screwdriver to open the mold along the marks. Tap the plastic out from the back through the nozzle connector, ensuring it is sufficiently cooled, and remove the dowel pin.

-

Cut all excess parts with pliers, then proceed with your creations.

Tools

- Safety gloves (~~example~~)

- Protective mask (~~example~~)

- 17 mm wrench (~~example~~)

- 4 mm Allen wrench (~~example~~)

- Slotted screwdriver (~~example~~)

Hardware

- Injection molding machine (~~example~~)

- Plastic shredder (~~example~~)

- CNC milling machine (~~example~~)

- Aluminum blocks (for mold components)

- Dowel pin (for star-shaped bead)

Software

Articles

- How to make silicone focal beads? - Beadable Bliss

- How to make silicone beads? - Beadable Bliss

- Make Silicone Molds from Charms - The Blue Bottle Tree

- ~~Lentil Bead Molds - Instructions - Glass With A Past~~

- ABS Injection Molding Manufacturing Factory - ZetarMold

- Ultimate Guide to Injection Molding | RapidDirect

- EPP Molding Process: The Ultimate Guide 2024 - Epsole

- Plastic Colorants Guide for Injection Molded Parts - RevPart

YouTube

Open Source Designs

- Premium Mould #3 - Bead Mould (3 Sizes) - [filtered]

- DIY Injection Molding - Instructables

- Beadifier - Create bead project from Image - GitHub

- Cocksmithing: Silicone Mold-Making - GitHub