Frequently, individuals inquire about achieving attractive patterns in beams, and interestingly, no special technical tricks are involved. The method aligns with standard practices, using a basic steel pipe mold and relying on the extruder's function. Here's how you can achieve similar results.

Table of Contents

-

In order to create patterns with distinct layers, use at least two colors. It makes no difference whether you work with PP (Polypropylene) or PE (Polyethylene), as there are no noticeable differences between the two in this context. Keep color mixes separate. The dark blue used here was mixed with transparent flakes, which serve as an effective filler. This allows you to use less dark blue pigment without compromising the output, as the pigments are usually strong. For example, adding 2.2 lbs (1 kg) of transparent flakes to 2.2 lbs (1 kg) of dark blue yields 4.4 lbs (2 kg) of dark blue material while maintaining color quality. The white used here is pure white.

-

Extrusion Process Guide

- Initial Setup: Add a few scoops into the extruder.

- Operation: Activate the machine and ensure the material is thoroughly melted.

- Mold Installation: Attach the cold mold and restart the machine.

- Material Addition:

- For the first color, use approximately 3 scoops total, accounting for any material already in the hopper.

- As the hopper nears empty, add 2 scoops of the second color.

- Adjust quantities as needed until the mold is filled.

- Cooling: Remove the mold to let it cool. While some suggest water cooling to avoid leakage, it is typically unnecessary.

-

Analysis of the Mixing Process

Upon sectioning the beam, observe the evolving pattern. Initially, the first color adheres to the mold's surface and begins to cool. Meanwhile, the inner core remains fluid, allowing subsequent colors to pass through. Repeatedly altering the input colors results in multiple layers within the beam. Proceed to the next step for further theoretical insights.

-

Another essential theory suggests that as plastic moves further into the mold, it cools, necessitating increased pressure for continued flow. The further from the inlet, the patterns become intricate due to variations in temperature and pressure. This phenomenon is particularly notable in square tubes, where flow slows at the corners. In contrast, round tubes likely produce circular patterns.

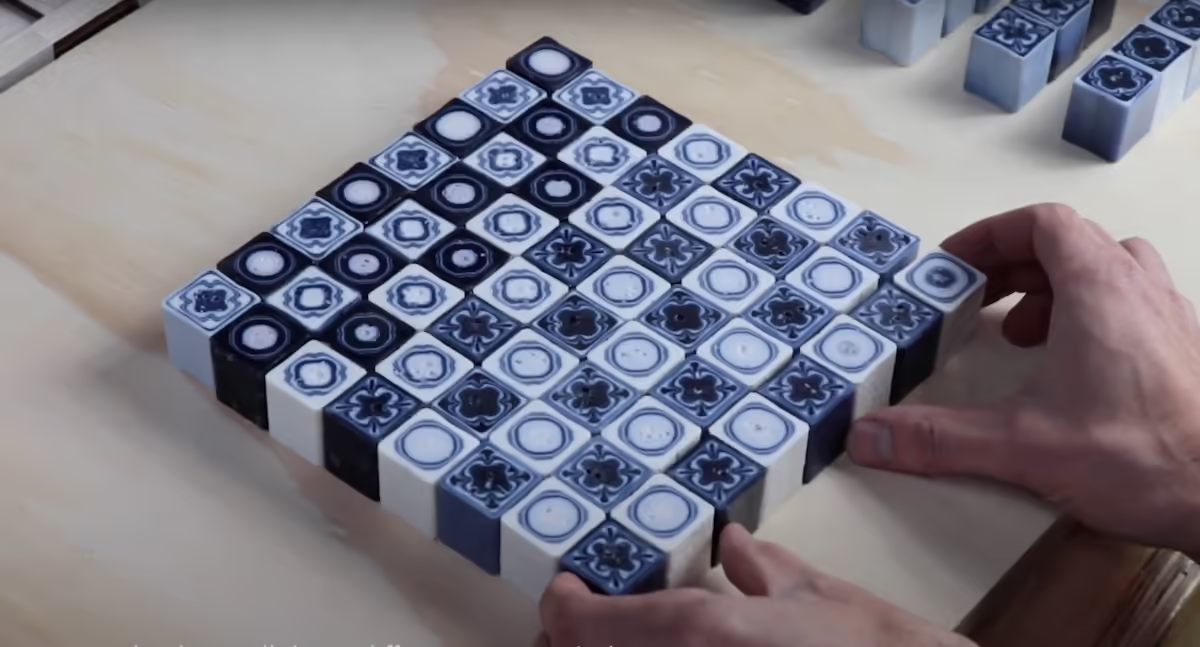

Refer to the video for the process of creating a chessboard with these beams. Thank you for reading, and enjoy your pattern-making!

Hardware

- Extruder machine

- Steel pipe mold

Tools

- Material scoops

- Water cooling setup (optional, typically unnecessary)

Software

- None specified

(Note: No explicit links were provided in the original text.)

Articles

- Plastic Extrusion Guide

- Understanding Plastic Extrusion

- Ultimate Guide to Plastic Extrusion

- Plastic Extrusion Process Guide

- Recycled Plastic Chessboard Tutorial

Books

- ~~Extrusion (ASM Handbook)~~

- Understanding Extrusion, 3rd Edition

- Extrusion Cooking: Cereal Grains Processing

- Extrusion: Definitive Processing Guide

- Extrusion Cooking (Harvard Book)

- ~~Understanding Extrusion (Reiter's Books)~~

Papers

- Finite Element Analysis of Extruded Aluminum

- Thermo-Chemo-Mechanical Model for Material Extrusion

- Finite Element Modeling of Bolt-Together Connectors