Create a climbing brush using plastic and woodworking techniques to achieve a unique pattern.

An oven is required; powered tools like a sander, saw, and router are recommended for ease.

For feedback or suggestions, please leave comments or contact us on social media.

Table of Contents

- Preparation

- Preparing Plastic (HDPE) Pieces

- Melting the Plastic

- Stack, Cut and Knead

- Melt and Repeat

- Forming Shape

- Cut the Block

- Glue the Outline and cut it out

- Sanding into Desired Shape

- Fill Holes

- Fine Sanding and Polishing

- Mill the Brush Head and Drill the Hole

- Insert the Hair

- Cut the Hair

- Go Climbing

-

Required Tools

- Oven

- Oven tray

- Two sheets of Teflon paper

- Oven gloves

- Mould: at least 12 in (30 cm) wide x 98 in (250 cm) long x 8 in (20 cm) high

- HDPE plastic

- White glue

- Saw (such as jaw saw or band saw)

- Sander (grit sizes: 40, 80, 120, 240, 400, 800, 1000)

- Polisher with wool pad

- Soldering iron

- Woodworking CNC router

-

For this project, use HDPE as it is easier to work with than PP. Ensure the plastic is clean and labels are fully removed. Cut the plastic into pieces and sort them by color.

The quantity of plastic depends on the mold size. For every 0.06 cubic inches (1 cm³) of volume, one gram of plastic is required. In this example, approximately 1.87 lbs (850 g) of HDPE is needed.

-

Place the plastic sheet on the oven tray with a Teflon sheet between layers. If the sheets do not stack well, transfer them to another container with a Teflon sheet.

Preheat the oven to 180-190°C (356-374°F) and heat the plastic for 25-30 minutes until fully melted.

-

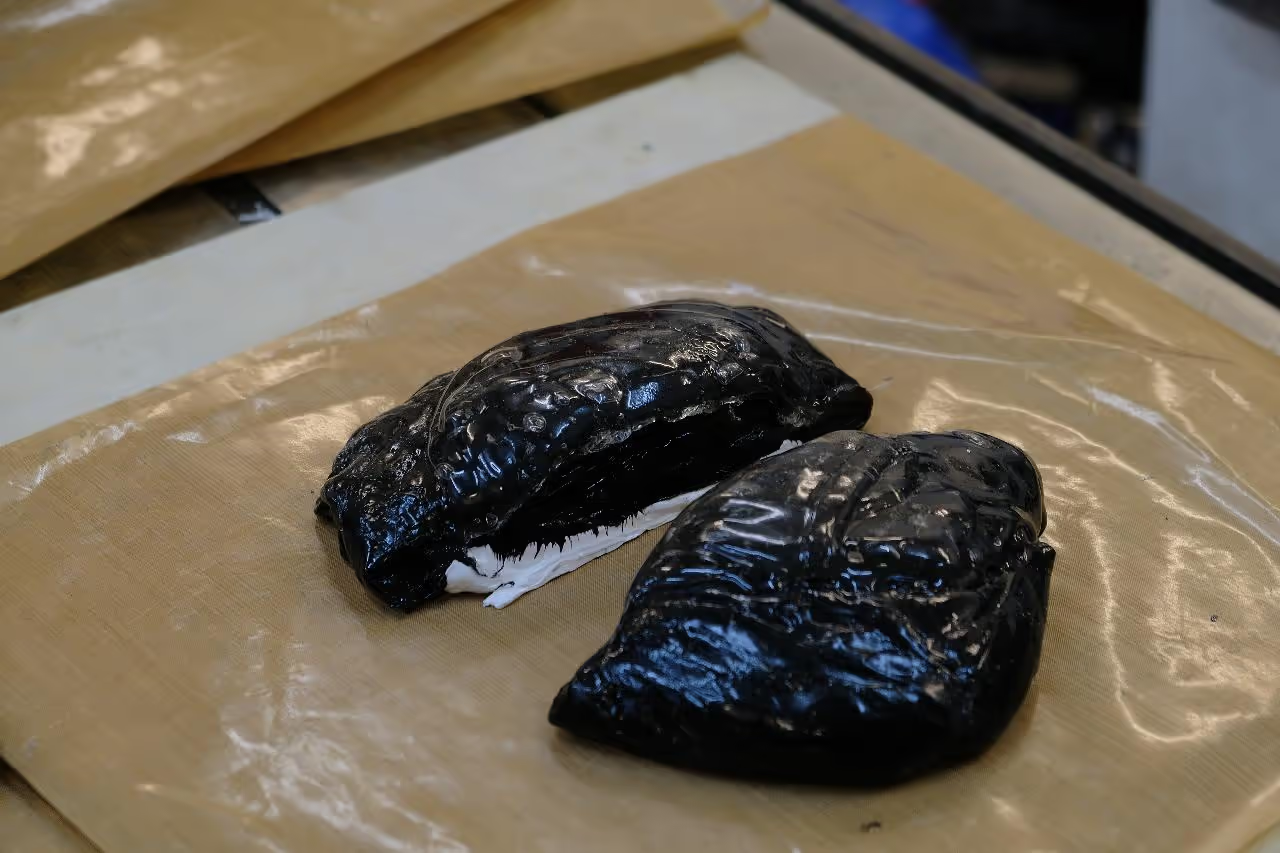

Remove the plastic while wearing thick gloves. Stack and cut the plastic, folding it as needed. Experiment to develop your method for layering different colors.

-

After allowing a few minutes to cool, the "dough" will become too firm to knead. Return it to the oven, melt, and repeat until the desired pattern is achieved.

-

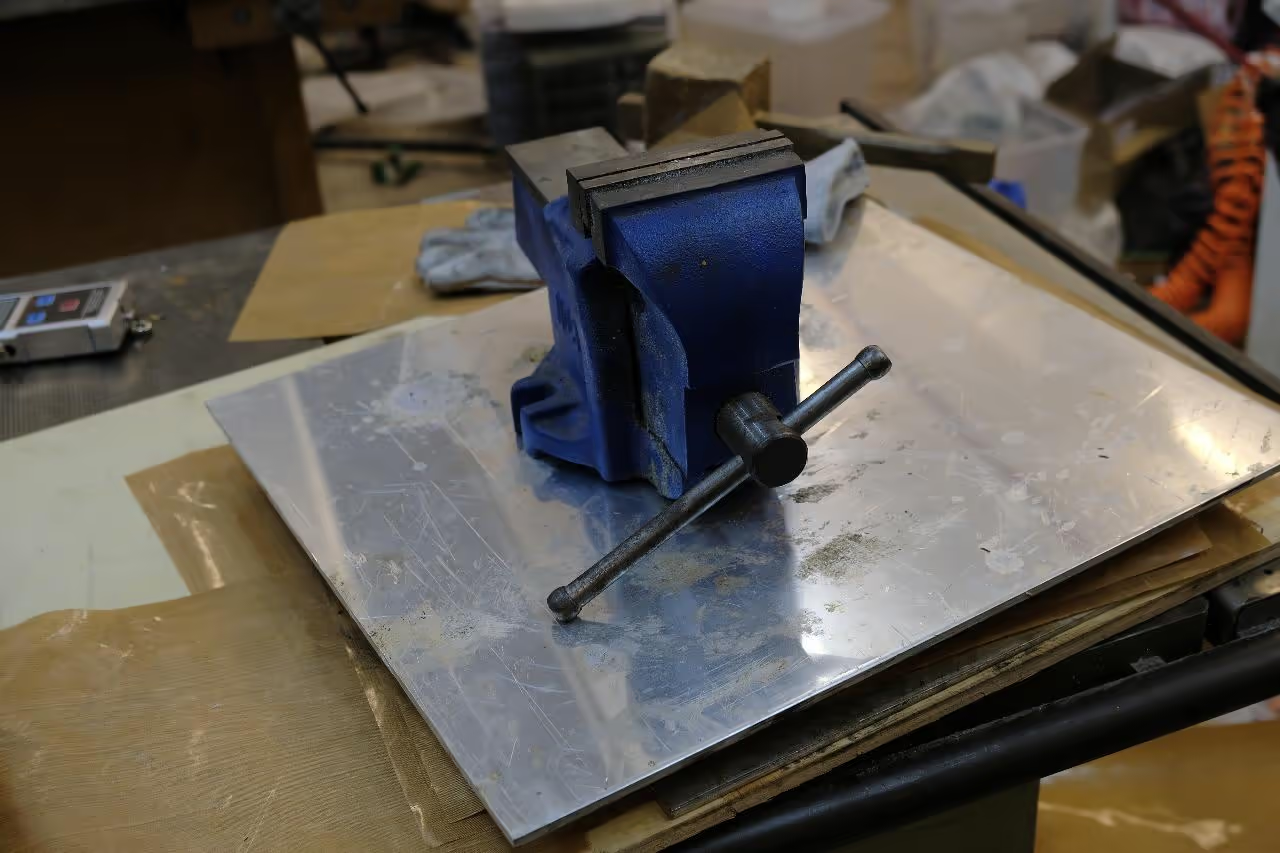

When satisfied with the mixture, place it into the mold and press with a heavy object. Allow it to cool.

-

If you have a larger mold, cut a strip approximately 1.18 in x 9.84 in x 0.98 in (30 mm x 250 mm x 25 mm) using a saw with a wood-cutting blade.

-

Print the outline of the brush to scale and attach it to the strip using white glue. If the surface is uneven, sand it smooth. Cut the outline with an offset of 2-3 mm (0.08-0.12 in) for additional sanding.

-

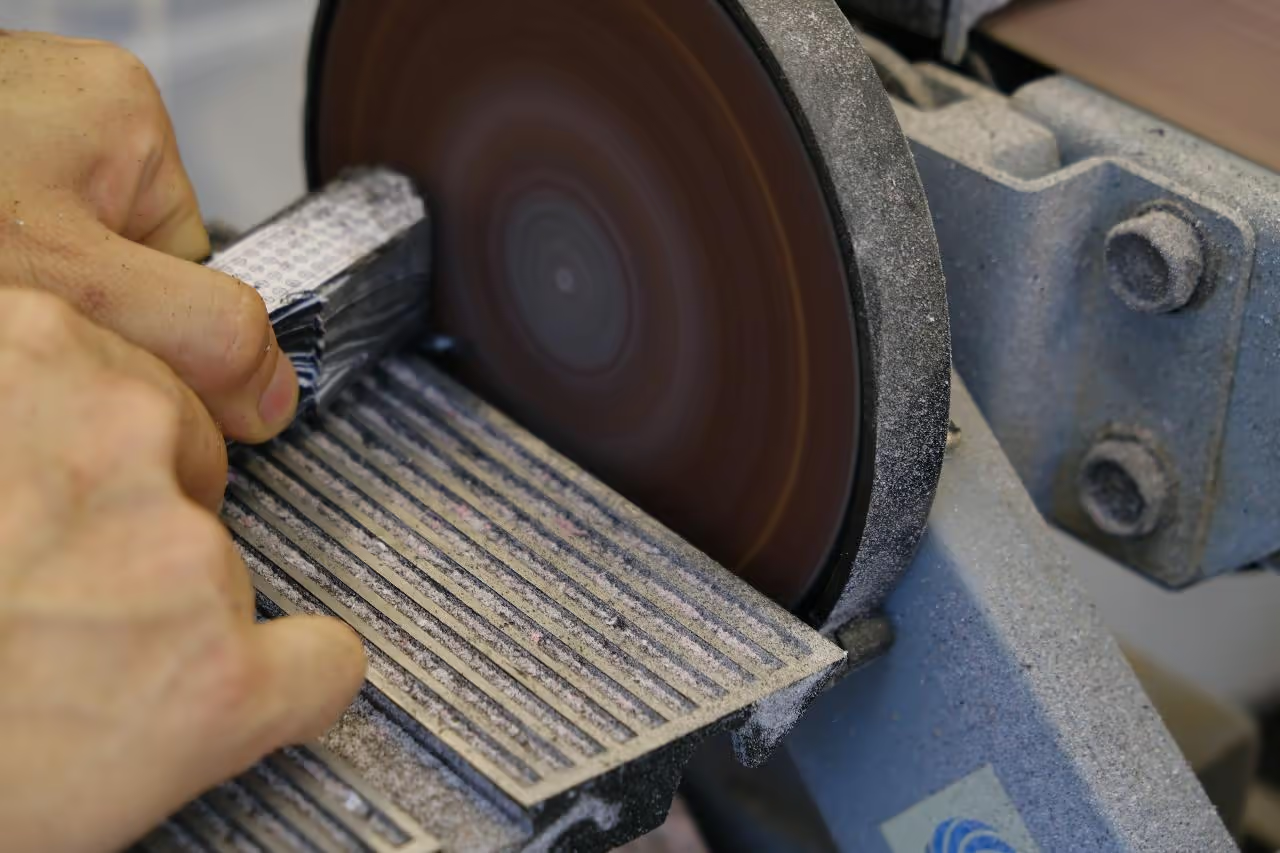

Sand the plastic to the desired shape using sandpaper with grits of 40, 80, and 120. Either a belt sander or a hand sander can be used effectively.

- 10Fill Holes

To address any gaps in the brush, use a soldering iron to fill them with leftover materials. Trim excess plastic with a cutter and sand the surface.

-

When the brush shape is formed, sand up to 1000 grit (18.5 microns). Then polish with a wool pad at high speed. If scratches appear, sand again. Wax can be used during polishing, but it is not essential.

-

Apply adhesive to the area to be milled on the brush, and then mill it with a CNC Router, keeping 1-2 mm (0.04-0.08 in) of the brush edge intact. Ensure the hole is at least 10-15 mm (0.39-0.59 in) deep to maintain the brush's firmness.

Alternatively, drilling holes is possible, but this significantly increases the time required for hair insertion.

Drill an M3-M5 (0.12-0.20 in) hole at the end of the brush to attach a rope.

REMINDER: Use masking tape to protect the brushes.

-

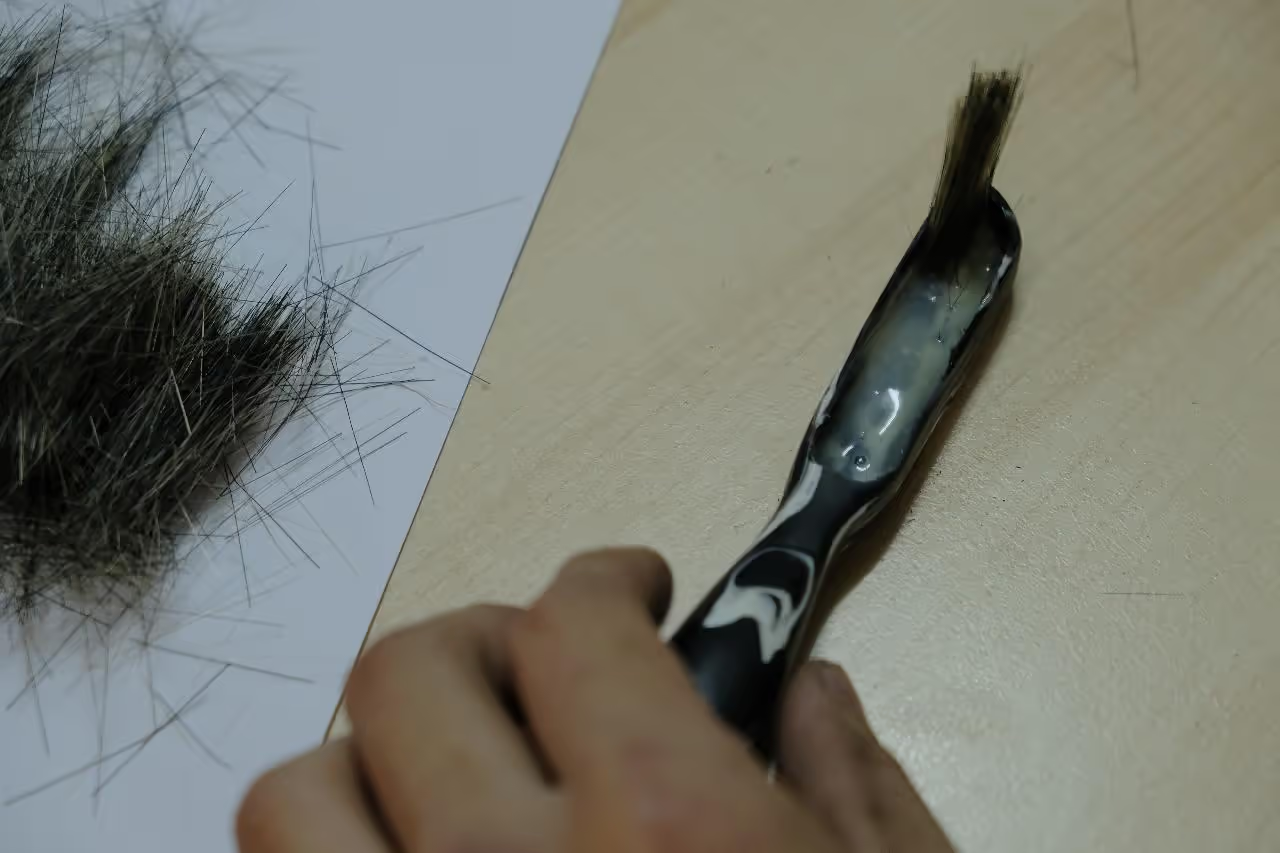

To insert the hair, use 1/8 to 3/16 inches (3-5 mm) of epoxy. Fill the area with hair until it is full. Allow the epoxy to set.

- 14Cut the Hair

To ensure the brush tip remains effective, maintain approximately 20 mm (0.79 inches) for the tip and 15 mm (0.59 inches) on the opposite end.

- 15Go Climbing

Create a climbing brush and use it at your gym or crag to clean holds effectively.

Tools

- Saw (jaw saw, band saw)

- Sander (grit sizes: 40–1000)

- Polisher with wool pad

- Soldering iron

- Woodworking CNC CNC Router

Hardware

- Oven (180–190°C / 356–374°F)

- Mould (12x98x8 in / 30x250x20 cm)

- Oven tray & Teflon sheets

- Drill (M3–M5 bits)

- Masking tape

Materials

- HDPE plastic (clean, label-free)

- White glue

- Epoxy resin (1/8–3/16 in / 3–5 mm thickness)

- Wax (optional for polishing)

- Rope (for brush attachment)

References

Articles

- Make a climbing brush - [filtered] Academy

- HDPE Blocks From Plastic Bottles - Instructables

- DIY Stick Brush - Climbing.com

- How to Clean Climbing Holds - Andy Librande

YouTube

Open-Source Designs

- BHToolset for 3D-Printable Climbing Holds - GitHub

- PeggyBoard Interactive Climbing Wall - GitHub

- Code Brushes (VS Code Tool) - GitHub Next