How to Build a Shredder Hopper

This guide outlines the simple process of creating a hopper for the 2.1 shredder using laser-cut stainless steel sheets. As shredders generally require laser-cut components, you can include the shredder cutout in your fabrication plans.

Requirements

- No welding necessary

- Completion time: less than a day

Tools Needed

- Angle grinder

- Vise

- Rivets

Features

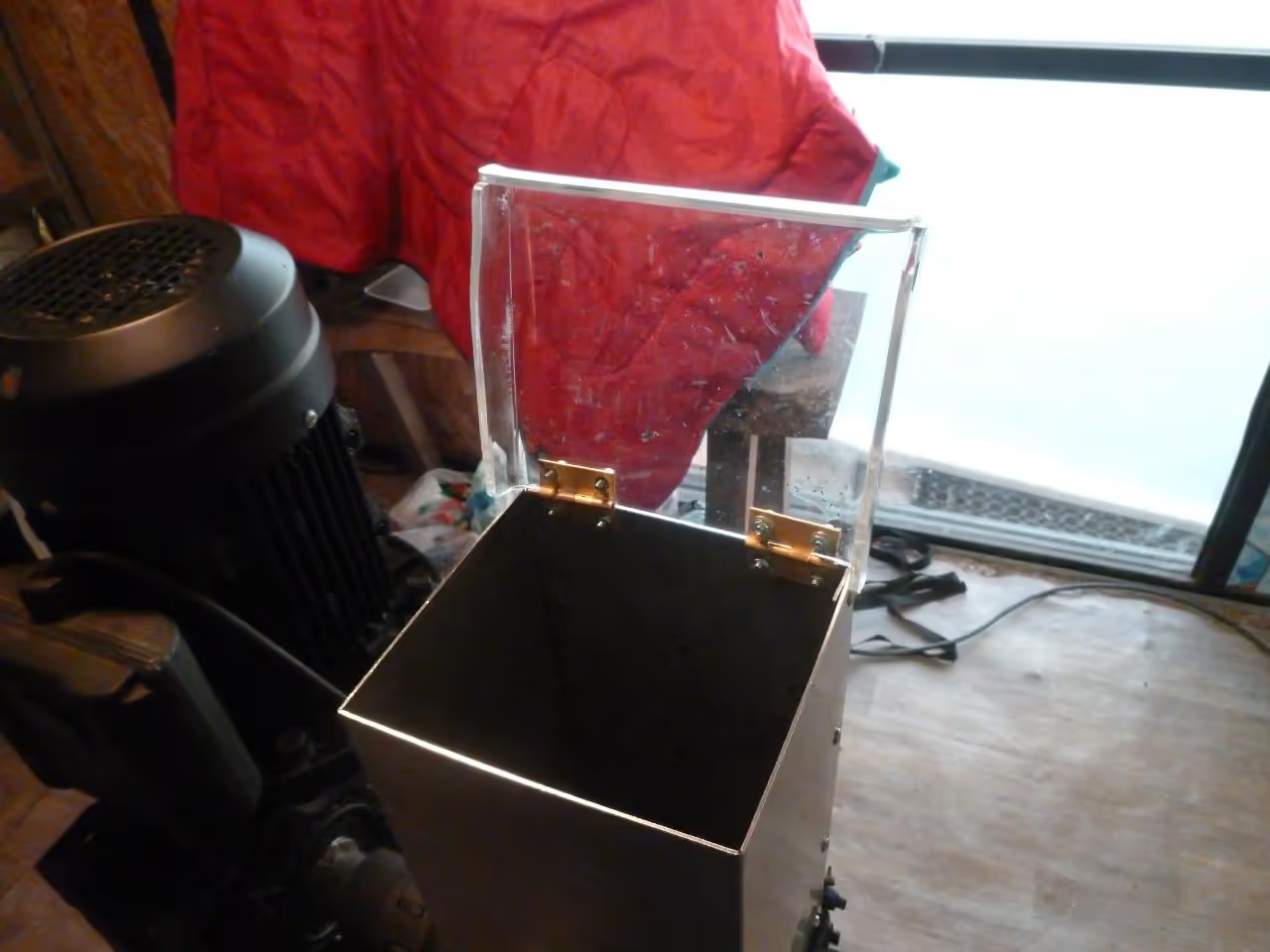

- Includes a laser-cut plexiglass lid for visibility of the shredding process

Table of Contents

-

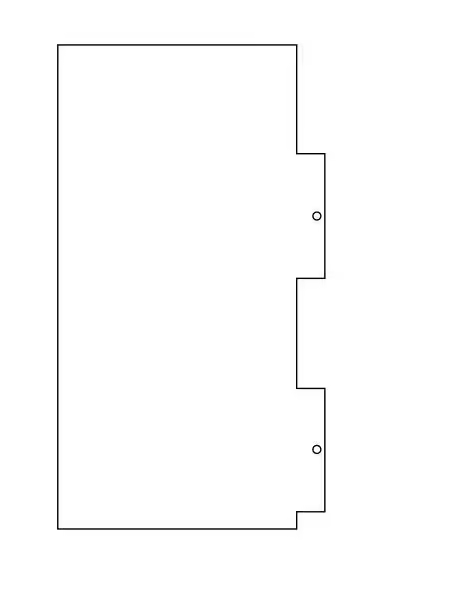

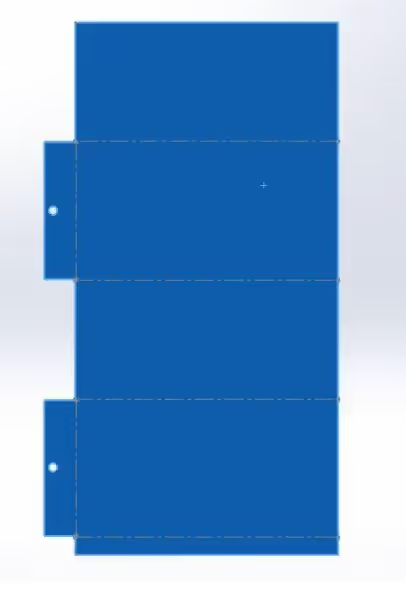

Submit the files to a laser cutting service. The design uses 1.5 mm (0.06 inches) thick stainless steel and 3 mm (0.12 inches) thick plexiglass. Plexiglass may also be processed at a local fabrication lab.

-

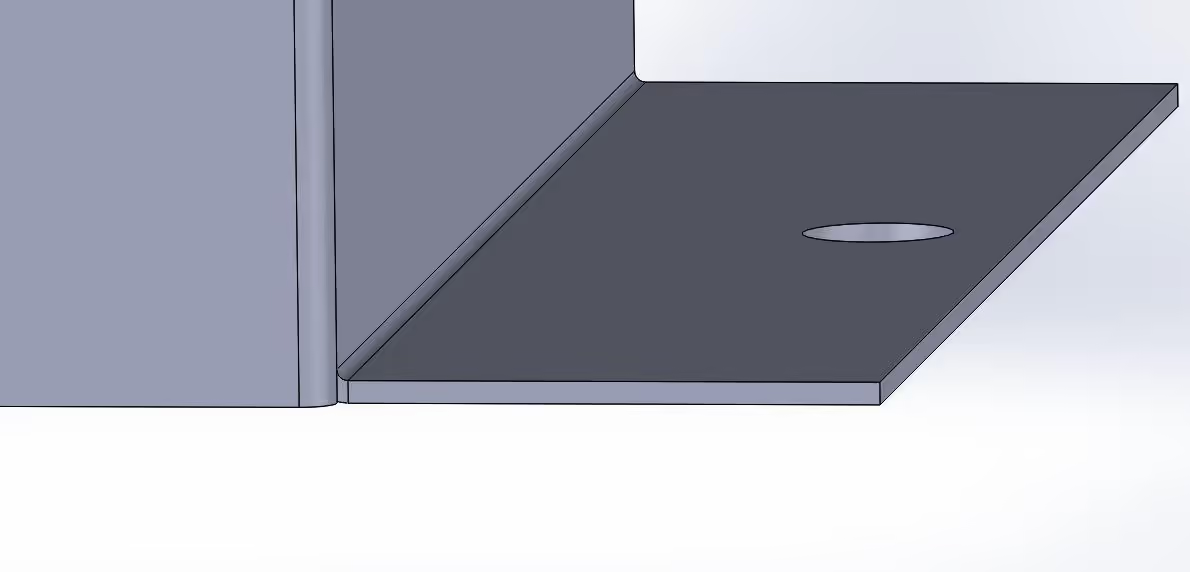

After completing the laser cutting, use an angle grinder with a 1/16 inch (1.5 mm) cutting disc to score the dotted lines. Grind halfway through the stainless sheet to facilitate bending. When grinding the small bend line for the mounting brackets, ensure the grind is above the line. This alignment is crucial to keep the mounting brackets flush with the hopper top and prevent plastic leakage.

-

Instructions for Bending Sheet Metal

-

Position the Sheet: Place the sheet in a sturdy vise along the marked line.

-

Bend the Sheet: Use pliers to bend the sheet along the lines, starting with larger bends.

-

Attention to Resistance: If significant resistance is encountered, stop and deepen the markings to achieve a smoother bend.

Note: Begin with larger bends before handling the hopper attachment bends.

-

-

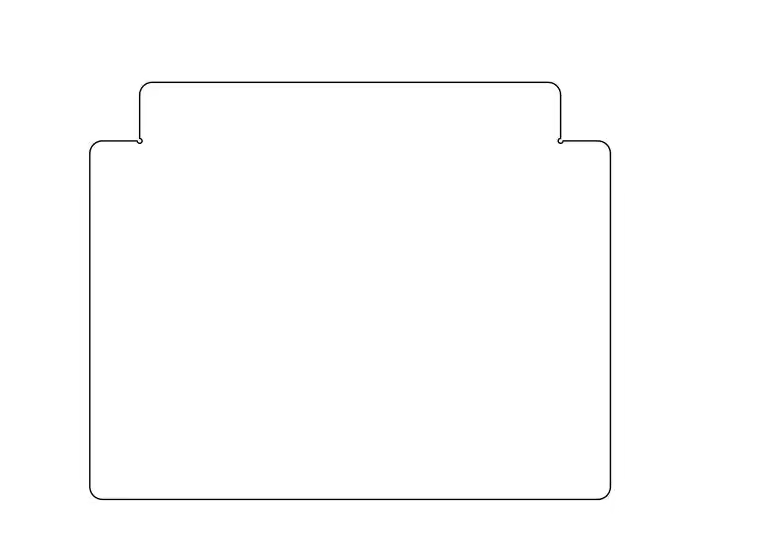

To simplify assembly, I marked lines on the fold points when laser cutting the plexiglass. To bend the edges, I clamped the part in a vise at the intended bend line and applied medium heat from a heat gun at approximately 8 inches (20 cm) away from the plexiglass until achieving a 90° angle. Avoid bringing the heat gun too close to prevent surface bubbling. Practice on a scrap piece of plexiglass or prepare multiple lids for best results.

-

You now have a functional hopper for your shredder. I used 230-grit sandpaper to smooth the surface and attached a small hinge at the back for the lid.

Tools

- Angle grinder with 1.5 mm cutting disc

- Vise

- Rivets

- Pliers

- Heat gun

Materials & Hardware

- 1.5 mm stainless steel sheet

- 3 mm plexiglass sheet

- Small hinge

- 230-grit sandpaper

Services

- Laser cutting service (for stainless steel and plexiglass)

- Local fabrication lab (optional plexiglass processing)

Links to specific services are not provided in the source text, but generic laser-cutting providers like Ponoko or local Ajaccio workshops can fulfill these requirements.

Articles

Papers

- Design and Construction of an Automated Paper Shredder with a Hopper

- ~~Open Source Waste Plastic Granulator~~

- Shredding Machine Development for Recycling Process of Waste Plastic Bottles

- Design and Development of Multi Purpose Shredding Machine