Jump rope is an effective fitness tool. This mold allows for making a jump rope handle and is designed for use with an injection machine. It is straightforward to operate.

Modifications to the mold may be required based on the specific configuration of the injection machine.

Local price is approximately 120 EUR (about $135 USD).

Table of Contents

- 1Download

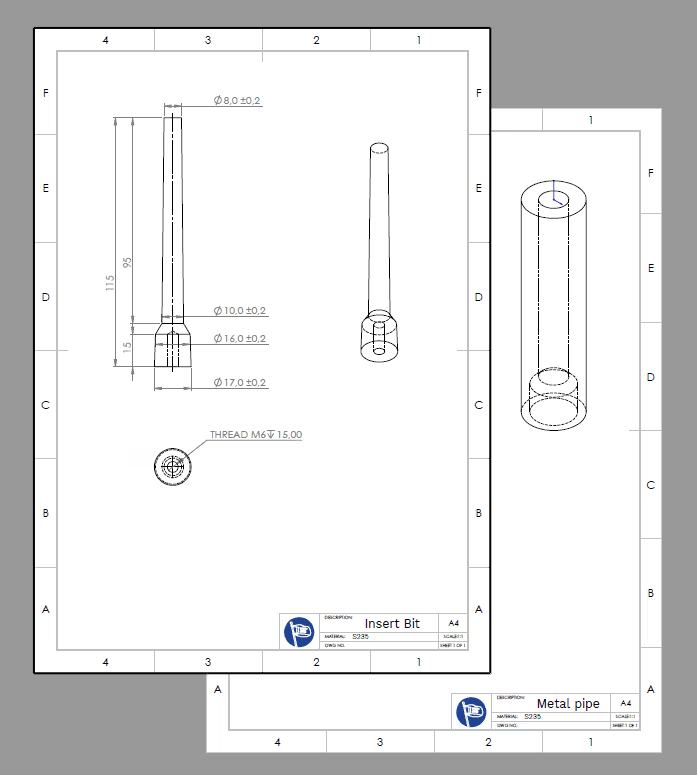

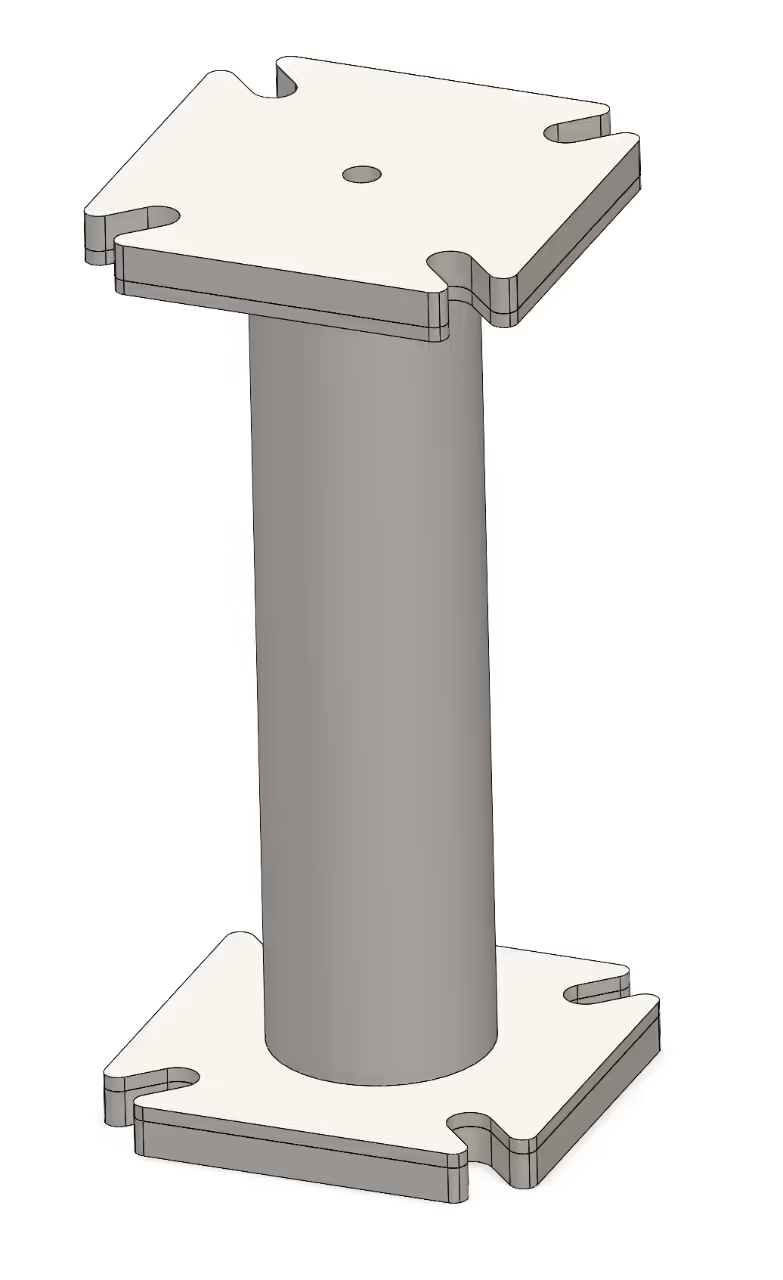

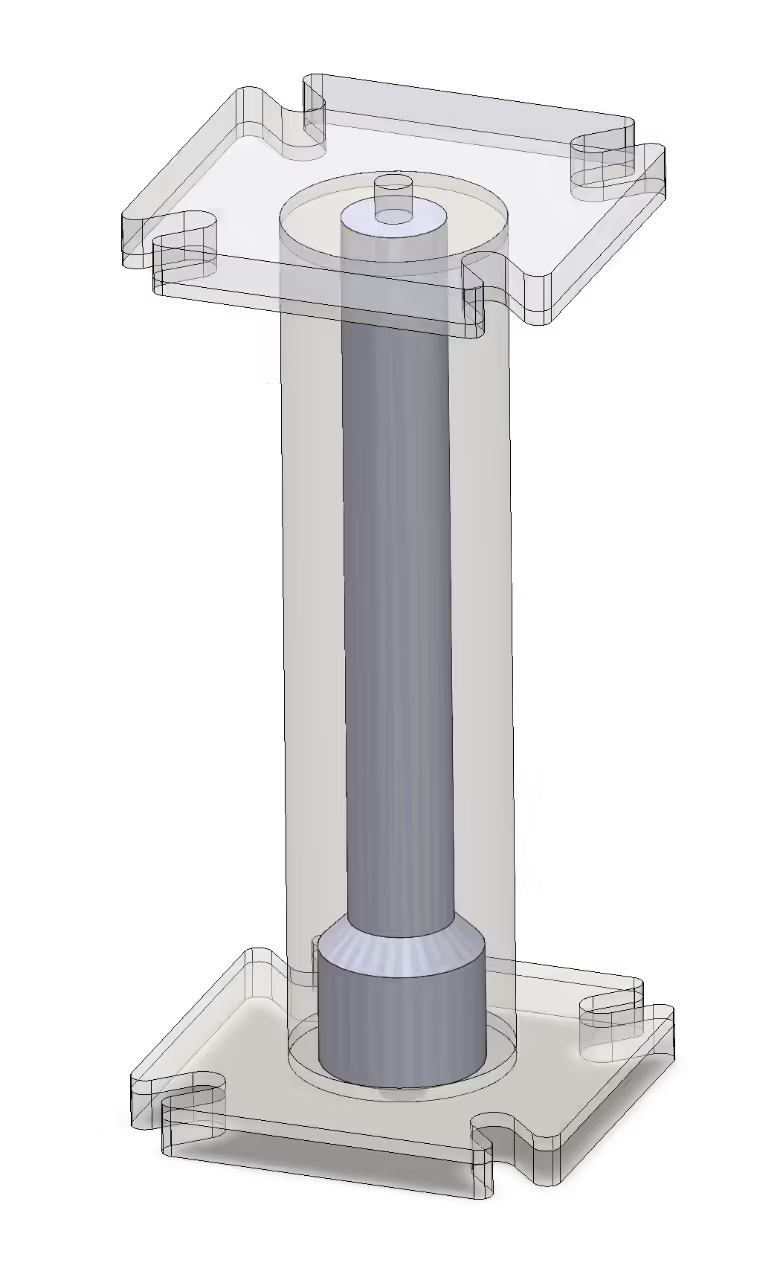

The design includes four laser-cut plates, a pipe, and an insert. The files are provided in all necessary formats for local fabrication orders.

-

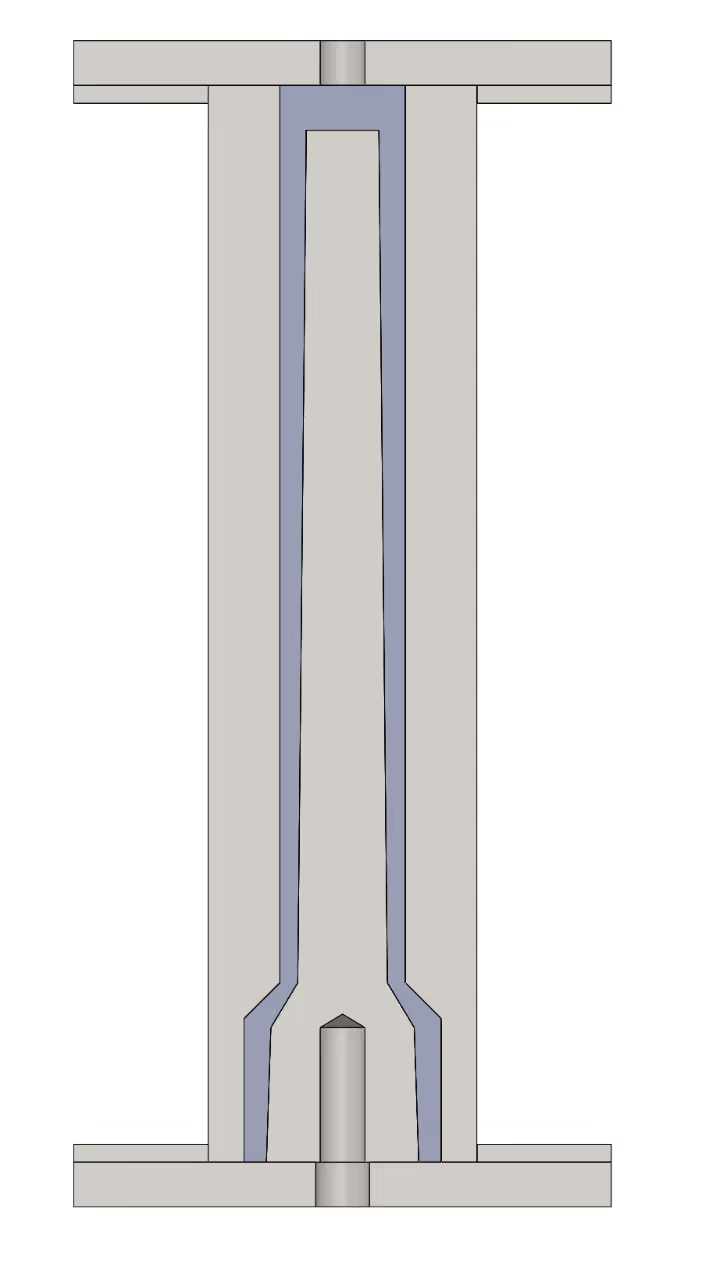

The pipe and insert require metal lathe work, which was outsourced to a local fabricator with drawings provided. The plates are laser-cut. The thicker plates support the pipe and insert, and one thick plate secures the insert with a bolt.

-

Injection Moulding Process

Preparation:

Begin by preparing the machine, material, and mould.Material Suitability:

- PP: Fills the mould effectively.

- HDPE: More viscous; requires higher injection pressure and is more challenging for this mould.

Mould Connection:

Ensure proper adapter or connection. A sturdy jack pushes the mould inlet onto the injection nozzle.Lubrication and Release:

Apply lubrication to the insert bit. If cooled too long, the product may shrink and stick. Use rubberized gloves and a twisting motion for release.Post-Processing:

Clip the injection point with pliers or a knife. Drill a 6-8mm (approximately 0.24-0.31 inches) hole at the end, preferably with a longer drill bit from the inside of the jump rope handle.Finishing Touch:

For the jump rope, use a 6mm (approximately 0.24 inches) paracord-type rope.

Tools

- Injection molding machine

- Laser cutter (for fabrication of plates)

- Metal lathe (outsourced for pipe/insert machining)

- Drill with 6-8mm drill bit (post-processing)

- Pliers or knife (clipping injection point)

Software/Design Files

- CAD files (provided in required formats for fabrication)

Materials

- Polypropylene (PP) or High-density polyethylene (HDPE)

- 6mm paracord-type rope

- Lubrication (for mold release)

- Laser-cut metal plates (thick and thin variants)

- Metal pipe and insert (requiring lathe work)

Safety Gear

- Rubberized gloves (for handling during release)

Hardware/Components

- Adapter or connection for mold-to-injection nozzle

- Bolt (secures insert to thick plate)

- Metal plates (4 laser-cut, varying thicknesses)

- Metal pipe and insert (lathe-machined)

- Longer drill bit (for internal hole drilling)

References

Articles

- Compression Molding vs. Injection Molding - Fictiv

- The Complete Guide to Polypropylene Injection Molding - TDL

- Injection Molding of Polyethylene

- Trouble Shooting in Plastic Injection Molding Machines (PDF)

Books

Papers

YouTube

Open Source Designs

Patents

- Compression/Injection Molding of Fiber Reinforced Composites

- Jump Rope Handle Design (WO1999038574A1)