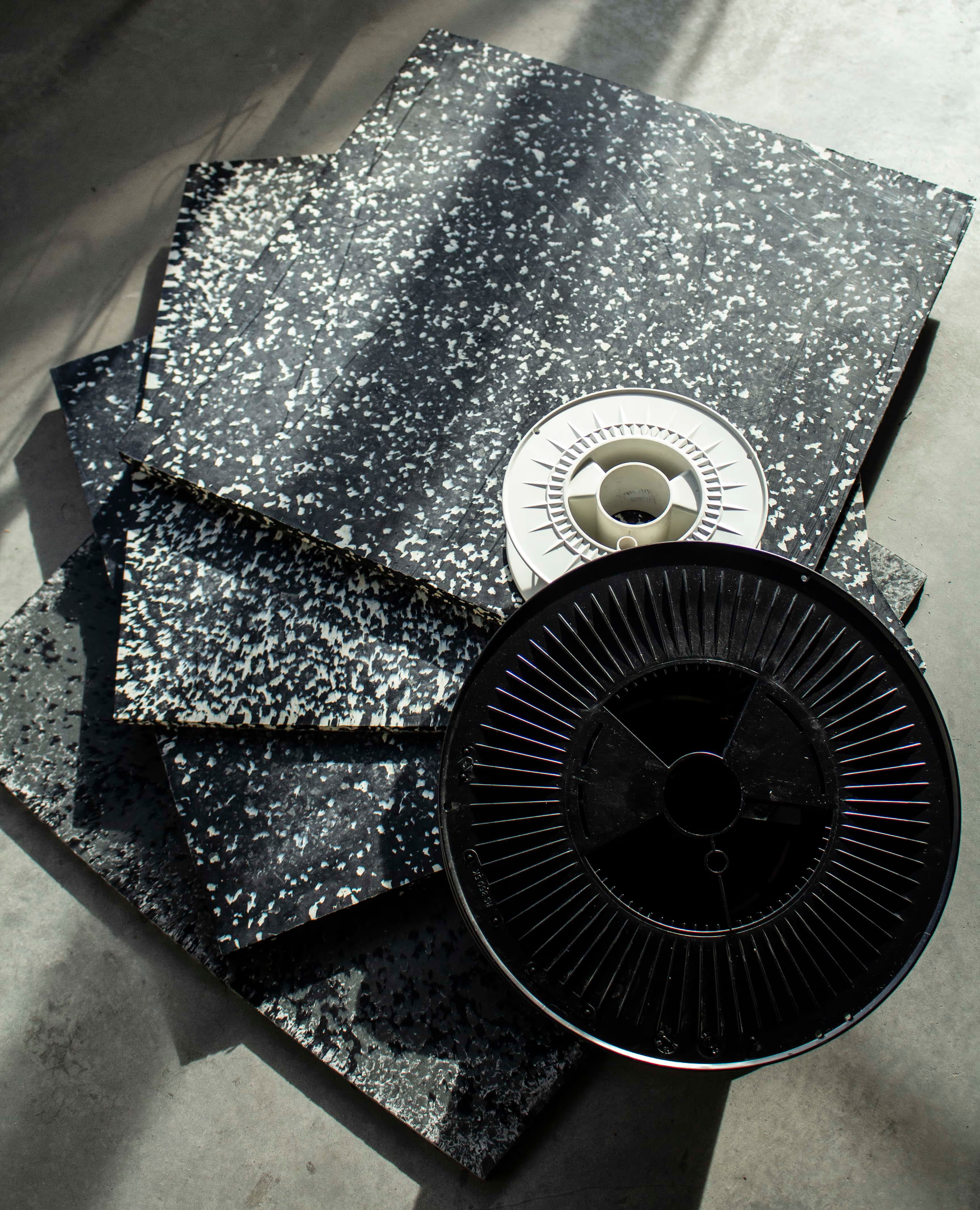

3D printing does not inherently generate waste; however, the spools used often become discarded by-products. After accumulating these spools for years, we have effectively repurposed them. Each sheet transforms 34 spools, rendering them suitable for diverse applications such as furniture and product design.

Table of Contents

-

First, sort the coils by material type, such as PP and PS, and use an industrial shredder to create particles with a uniform texture of about 0.2 inches (5 mm).

-

Assembly Instructions for Mould

To assemble the mould, begin by placing a thin metal sheet coated with natural wax within it. Next, position the structure according to the desired shape and size. For this example, the mould measures 60 x 60 cm (24 x 24 inches) and is 2 cm (0.8 inches) thick. The material usage for this mould is approximately 8 kg (17.6 lbs).

-

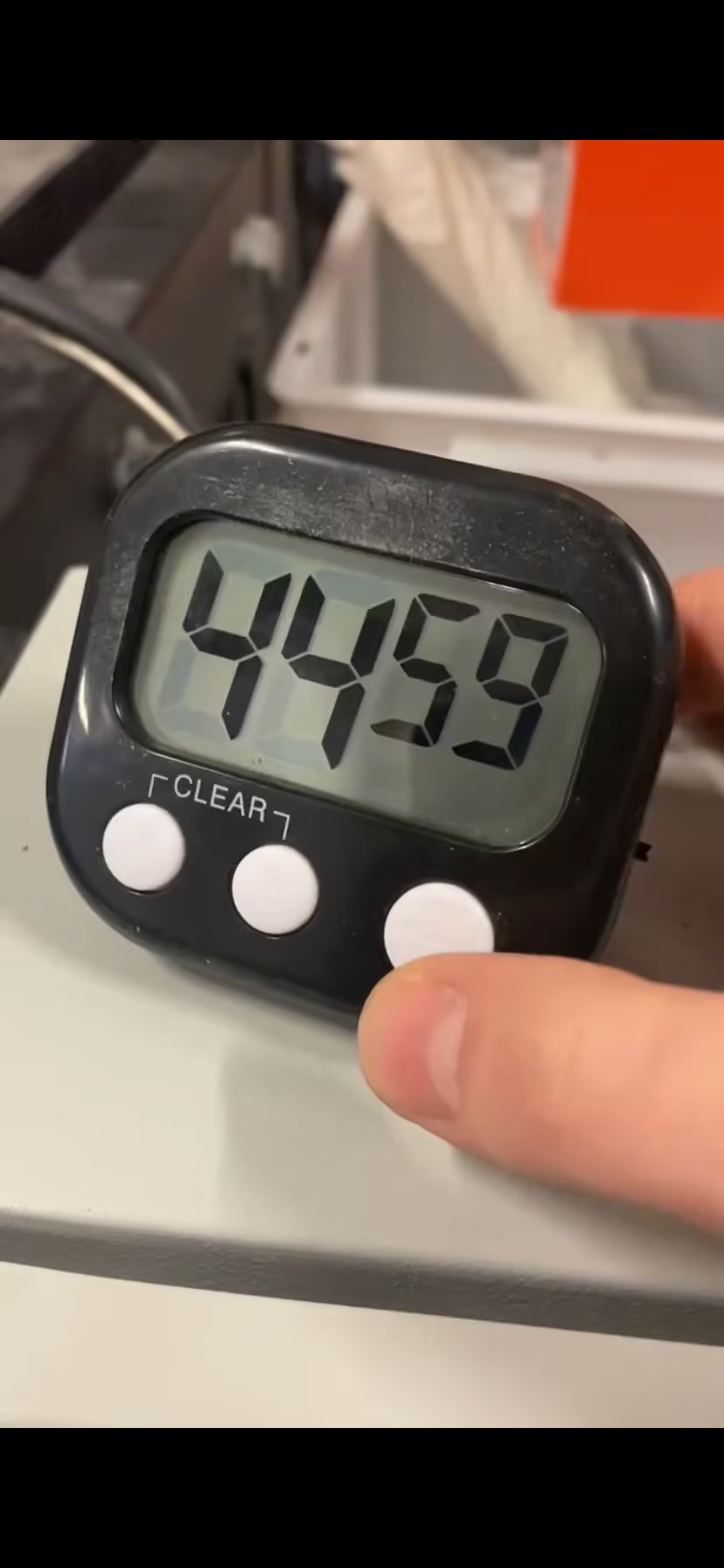

Place the material inside and cover it with another sheet of waxed metal to prevent sticking. Activate the press and heat to 230°C (446°F) for 45 minutes or until the plastic begins to overflow. Allow it to cool after the heating period.

3D printing waste reduction through spool repurposing involves industrial tools and custom fabrication processes. Below are the key components required for transforming plastic spools into sheets for design applications.

Tools

- Material sorting system (for PP, PS, and other plastics)

- Precision measurement tools (for 5 mm particle uniformity checks)

- Thermal control devices (for monitoring 230°C/446°F temperatures)

- Wax application equipment (for metal sheet coating)

- Cooling timers (for post-press hardening)

Hardware

- ~~Industrial shredder~~ (5 mm particle output capacity)

- ~~Heated hydraulic press~~ (60x60 cm platen size)

- ~~Custom aluminum mold~~ (24"x24"x0.8" dimensions)

- ~~Wax-coated steel sheets~~ (food-grade release surfaces)

- ~~High-capacity drying racks~~ (for post-processing)

Consumables

- 8 kg plastic spool material per sheet

- Natural wax release agent

- Heat-resistant mold seals

- Protective gloves (for 230°C operations)

- Insulation materials (thermal process safety)

All listed equipment can be sourced from industrial suppliers in Madrid like ~~Hercort~~ for shredders or ~~Tecni-Molde~~ for custom molds.

Articles

- How to Recycle PS Spools into 3D Prints: A DIY Guide

- 3D Printing with Recycled Plastic: Sustainable Solutions for the Future

- Closed-loop additive manufacturing fueled by upcycled plastic

- Sustainable 3D Printing: Create and Use Recycled Filament

- Environmental Benefits of 3D Printing with Recycled Filament

- Polyformer: from PET bottles to 3D printing filaments

- Recycle plastic waste into 3d printing filament

- Combination 3D Printer will Recycle Plastic in Space

Books

Papers

- Closed-loop Additive Manufacturing of Upcycled Commodity Plastic through Dynamic Crosslinking

- ~~Exploring Computational Media as a Possible Future of Software~~