Using the Injection Machine

This injection machine uses a motor to reduce manual effort and increase pressure for creating detailed products.

Table of Contents

-

Machine Design:

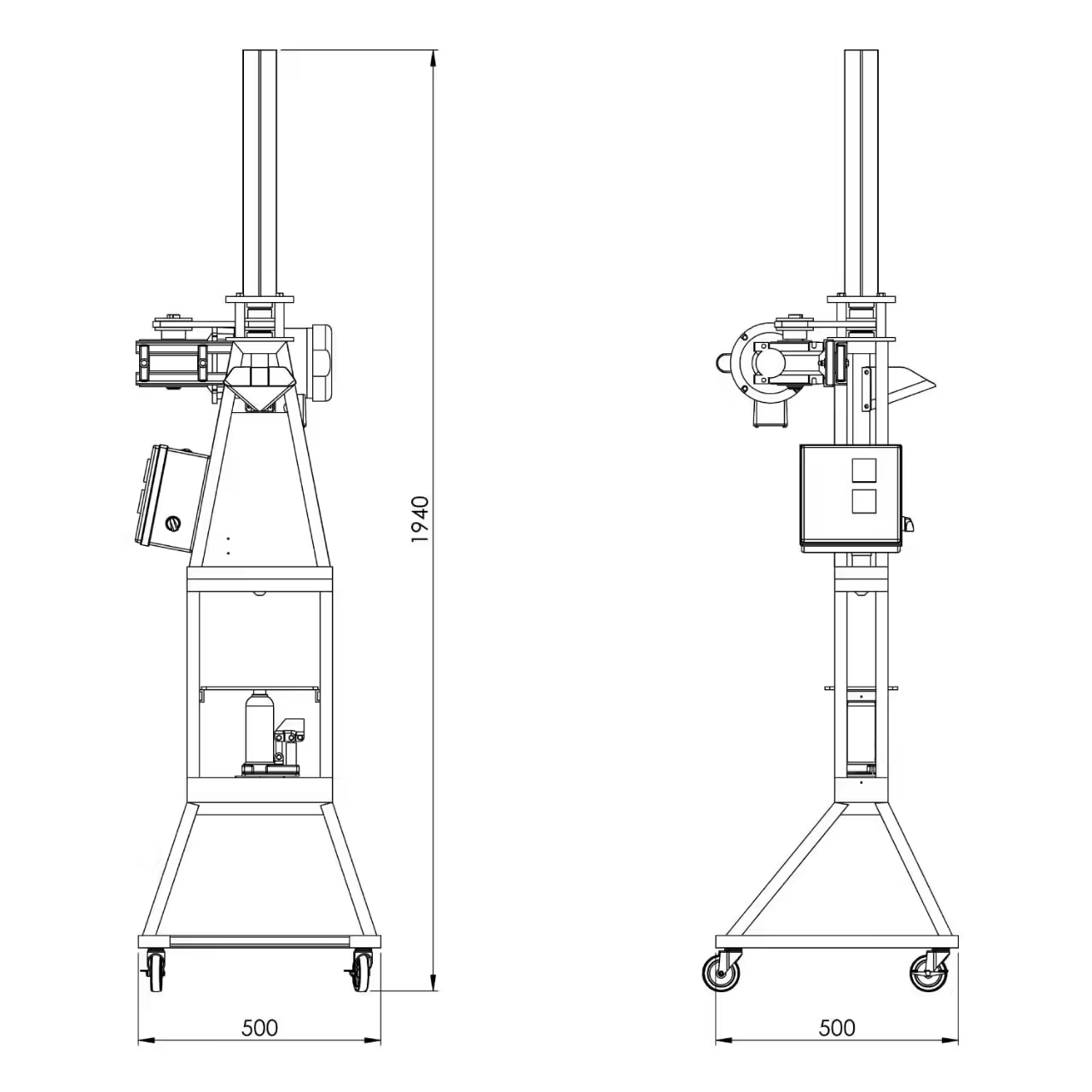

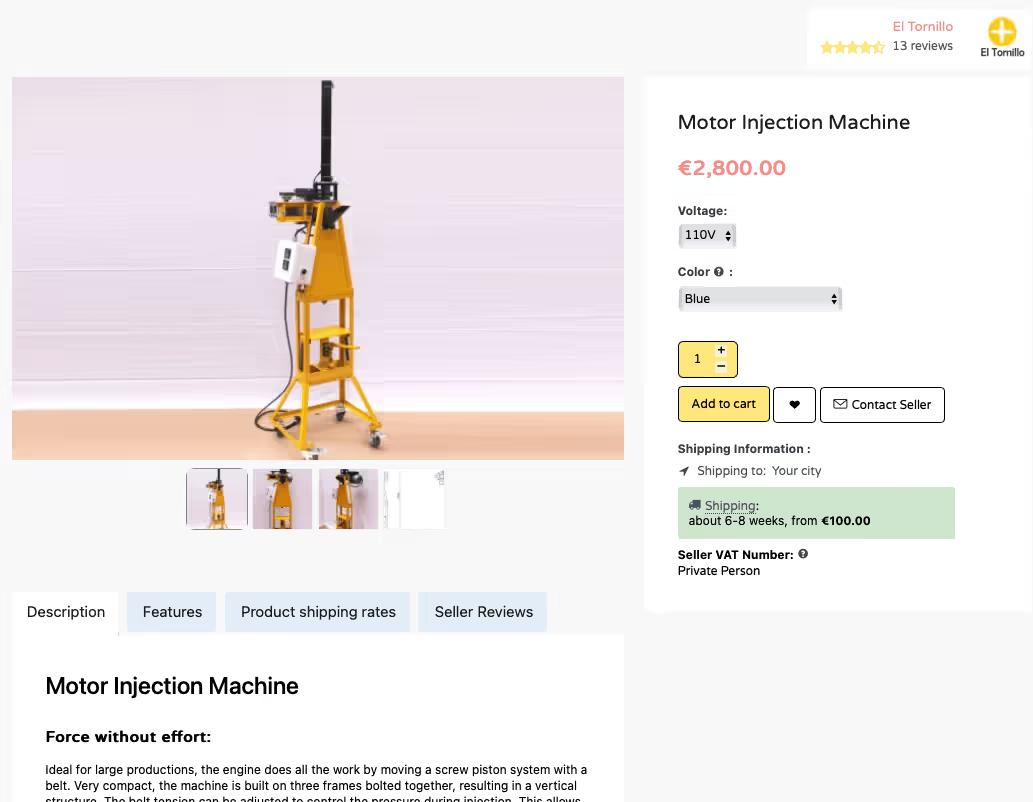

Motor Injection MachineMachine Size:

Height: 76.77 inches (195 cm); Width: 19.69 inches (50 cm); Depth: 19.69 inches (50 cm)Machine Cost:

In Colombia, Bill of Material: COP $4,700,000Features:

Equipped with a motor for pressure application, improving upon older hand-lever models.Compatibility:

Suitable for injection molds.Compatible Plastic Types:

PP, HDPE, LDPE, PS -

To build this machine, you will need:

- Turning (machining on a lathe)

- Milling (machining on a mill)

- General metalworking (cutting, drilling)

- Welding

- Advanced assembly work (requires specific tools, measurement instruments, and knowledge of tolerances for alignment and assembly)

- General electrical work (wiring safety switches, temperature controllers)

- Motor electrical work (wiring motors, contactors, overload protection)

-

Watch this video for instructions on building the machine:

0:00 Introduction 3:09 Motor Injection Machine Overview 3:36 Chapter I: Frame Construction 7:12 Chapter II: Mould Area Assembly 8:25 Chapter III: Piston System Installation 14:39 Chapter IV: Heating Barrel Setup 17:51 Chapter V: Electrical Wiring 18:56 Chapter VI: Motor Connection 20:10 Chapter VII: Final Assembly

- 4Inject!

How to Operate the Machine

- Activate the machine and load the barrel with plastic.

- For the initial injection, allow 25 minutes after activation and loading.

- Position the mold on the jack surface and press it firmly against the nozzle.

- Engage the motor to lower the piston, forcing the molten plastic into the mold until the belt slips in the pulley.

- Deactivate the motor and maintain piston pressure for approximately 5 seconds.

- Reverse the motor to raise the piston.

- For continuous use, refill the barrel before detaching the mold from the nozzle.

- Lower the jack to remove the mold.

- Open the mold and extract the molded part.

- Close the mold and repeat the process from step 3.

Recommendations

Molds must feature a conical nozzle connection or require an adapter. The machine generates significant pressure, allowing for the injection of items with thin walls.

-

This guide outlines the process for constructing a Motor Injection Machine.

For those unable to replicate the machine or interested in purchasing other machines or molds, please visit my shop.

Tools

- Turning (machining on a lathe) – Chapter I (3:09)

- Milling (machining on a mill) – Chapter II (7:12)

- Welding equipment – Chapter I (3:09)

- Cutting/drilling tools (metal saw, drill press) – Chapter I (3:09)

- Measurement instruments (calipers, micrometers) – Chapter III (8:25)

Hardware

- Motor for pressure application – Chapter VI (18:56)

- Safety switches – Chapter V (17:51)

- Temperature controllers – Chapter V (17:51)

- Contactors and overload protection – Chapter VI (18:56)

- Injection molds (PP, HDPE, LDPE, PS compatible) – Chapter II (7:12)

Software

- None specified in the tutorial

This summary distills key requirements for constructing the injection machine, referencing timestamps from the instructional video.

Articles

- Injection Molding Technology Overview | Xometry Pro [1]

- DIY Injection Molding: How to Mold Plastic Parts In-House - Formlabs [4]

Books

- Injection Molding Reference Guide (4th EDITION) [2]

- Scientific Molding, Recommendations, and Best Practices [7]

Papers

YouTube

- Build an Injection Molding Machine From a Cheap Pneumatic Press [3]

- Injection molding setup and run - YouTube [8]