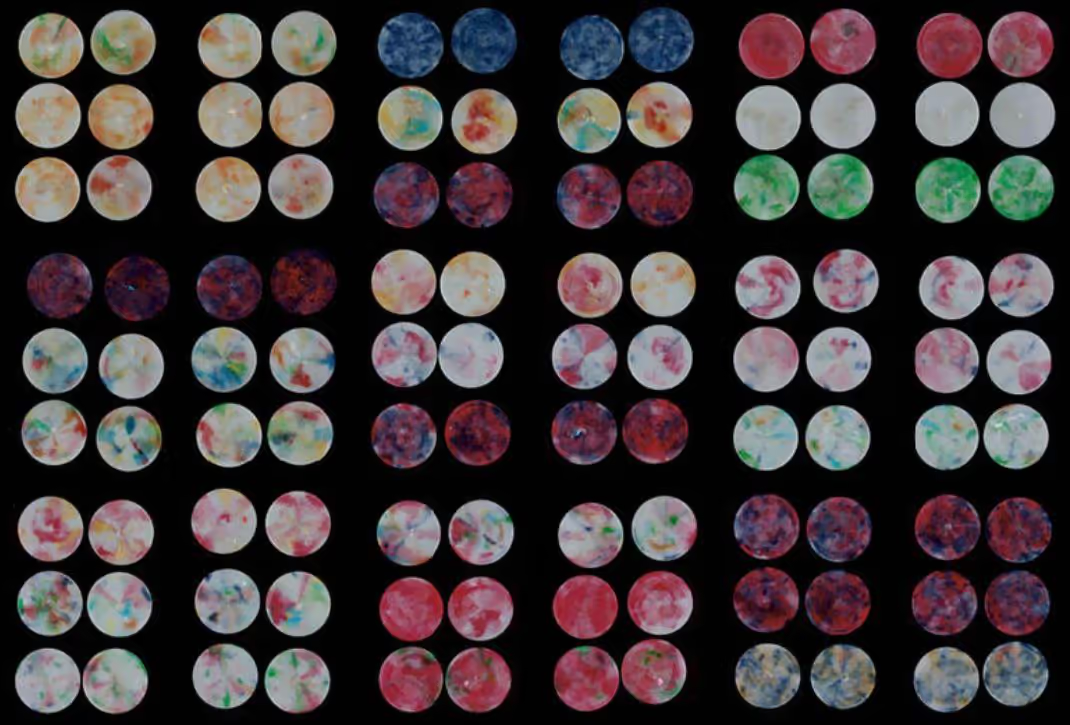

Hello, we created a lamp to explore translucent HDPE properties. By sorting shredded transparent and colored bottle caps, you achieve a liquid-like effect. The key is in your color choice, allowing for diverse visual outcomes.

Table of Contents

-

Collect HDPE bottle caps from a local source. To achieve a liquid-light effect for your lamp, use both transparent and colored caps. Adding a small amount of shredded colored plastic will tint and alter the final appearance. Sort and shred the plastic carefully.

-

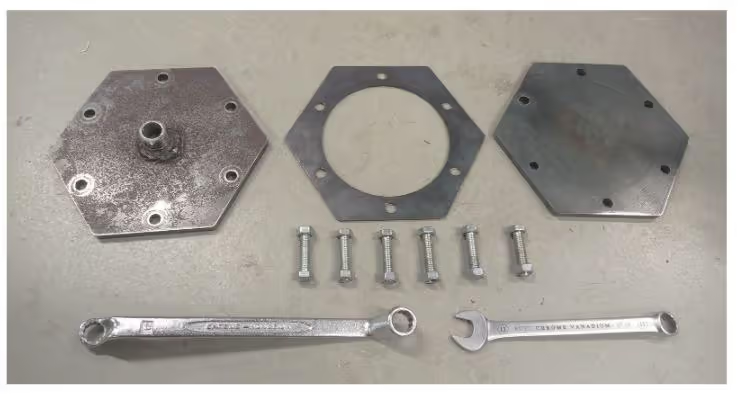

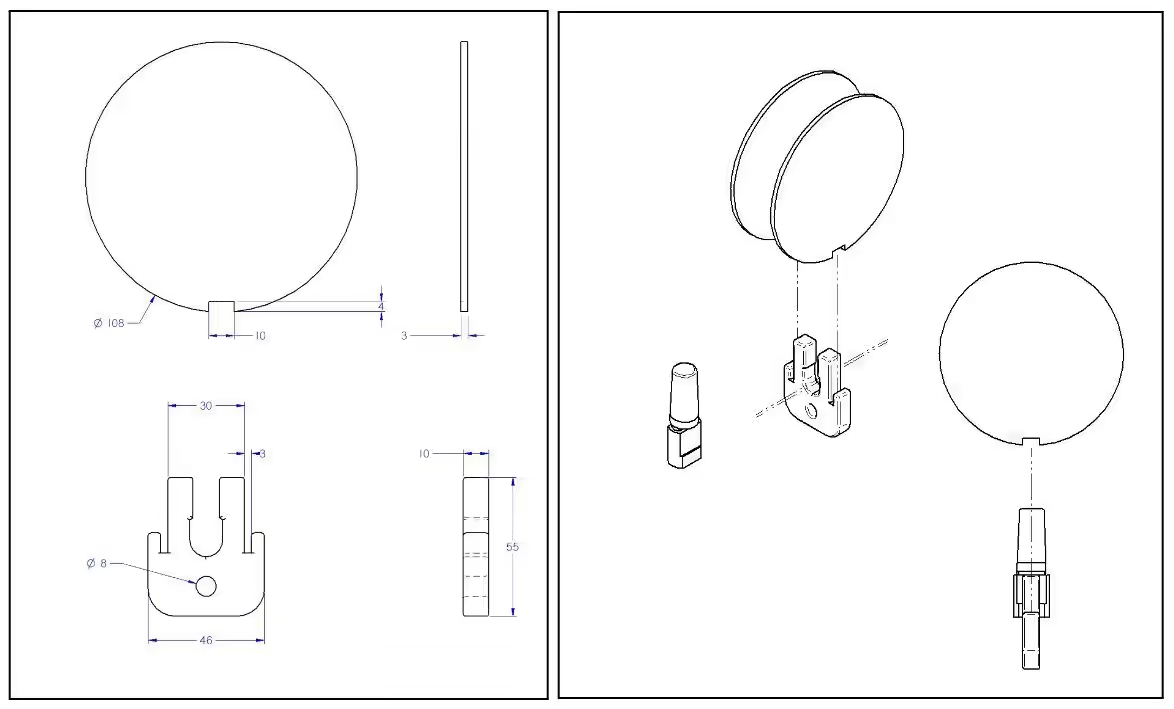

In the initial image, the light bulb is positioned between two discs. Begin by creating the discs using injection molding. The mold has a thin wall thickness of 3 millimeters (0.12 inches). Refer to the Academy for melting temperatures for HDPE. Experiment with various color combinations. Each disc requires less than 30 grams (1.06 ounces) of material, so adding 3 or 4 grams (0.11 or 0.14 ounces) of color will suffice to tint the plastic.

-

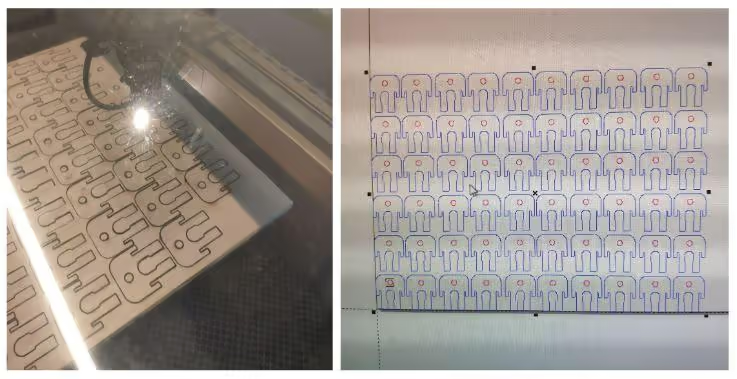

The clamp for the discs is constructed from wood. We utilized a laser cutting machine at a local makerspace to produce the wooden components. The wood is 0.39 inches (1 cm) thick, and the CAD drawings are included in the download package. The clamp is tailored to accommodate a specific lamp holder and bulb, but you may adjust the design for lamp holders available at local stores. The wooden pieces were later spray-painted.

A small square indentation must be cut from the disc to allow it to attach to the wooden part securely. This feature enables you to swap out discs without using adhesive, facilitating various lighting effects.

-

Assembling the lamp should be quick, as all parts are designed to fit securely. If the structure is unstable, apply glue for reinforcement. You can place it on a bedside table, a desk, or hang it. We would appreciate seeing your completed work.

To create the HDPE lamp described, you'll need the following tools, software, hardware, and materials:

Tools

- HDPE bottle cap collection (local sources in Donostia/San Sebastian)

- Plastic shredder for processing caps

- Color sorting system for translucent/colored caps

- Injection molding equipment with 3mm-thick molds

- Spray paint for wooden components

Software

- CAD software to modify wooden clamp designs (drawings included)

Hardware

- Laser cutting machine (available at local makerspaces)

- Injection molding system for disc production

- Standard lamp holder and bulb assembly

Materials

- Transparent/colored HDPE bottle caps

- Shredded colored plastic (3-4g per disc for tinting)

- 1 cm thick wood sheets for clamp construction

- Spray-paintable wooden components

- Adhesive (optional reinforcement)

The lamp's modular design allows customization using locally available materials and makerspace equipment. Total material per disc stays under 30g HDPE with <5g color additives[1][2][4][5].

References

No external reference links were provided in the text to process.