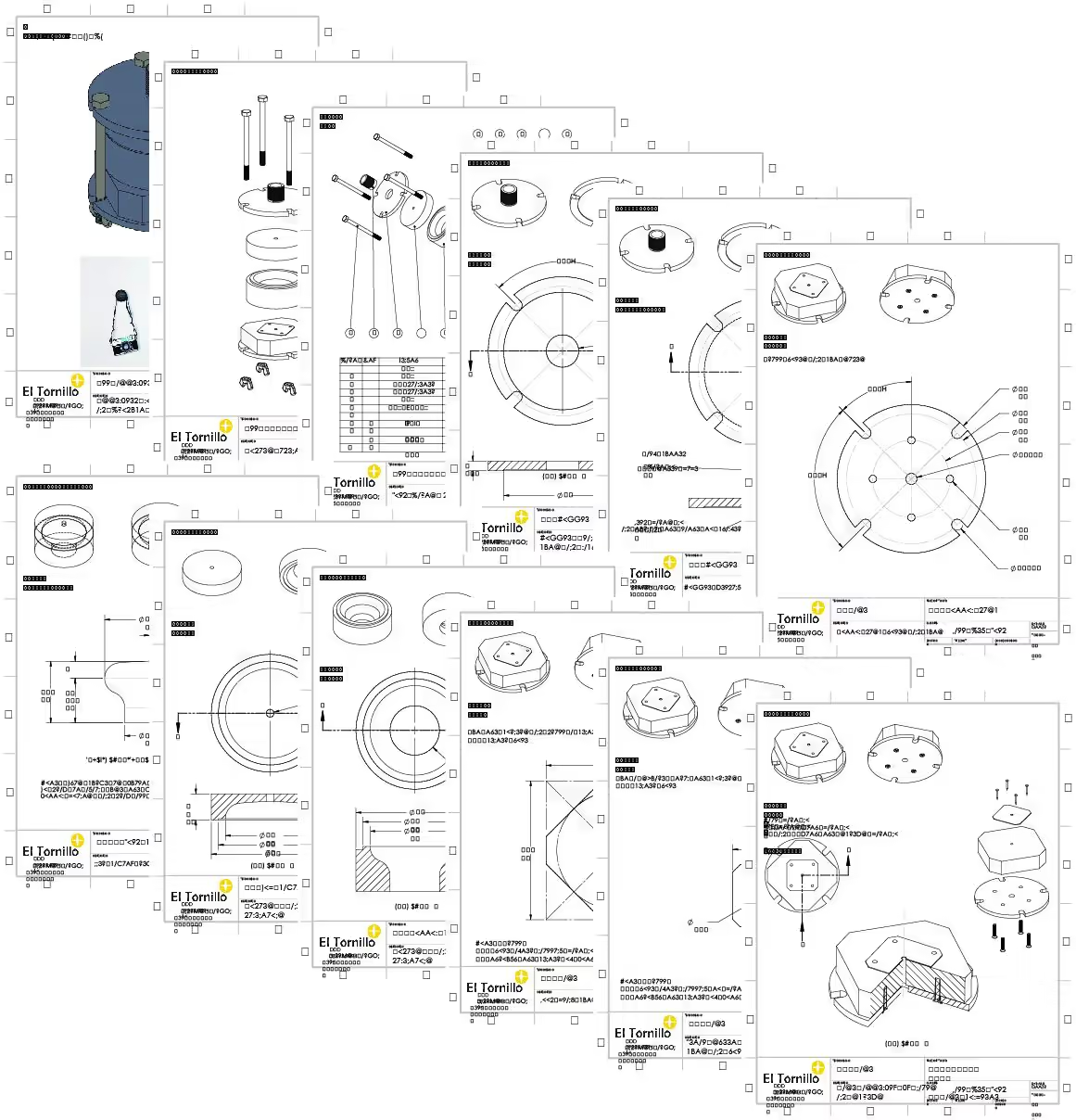

Access 3D models and blueprints to create the wall peg mold here.

Table of Contents

- Get your materials and prepare the work:

- Cut the nozzle nipple:

- Make the nozzle flange:

- Turn the nozzle guide

- Weld the nozzle

- Drill the base center hole

- Drill and cut the screw holes

- Drill the base fixing holes

- Get your CNC turned parts

- Make the mold base

- Cut the metal sheet

- Drill the screw holder hole

- Done!

- Happy hanging :)

-

Ensure all materials are prepared. Review the drawings and steps to understand the process fully. This will enhance efficiency and accuracy.

-

Instructions for Makers

Begin by cutting the steel pipe nipple (part no. 7) in half to create the mold nozzle. (Refer to Drawings, page 3).

-

Retrieve the steel disc (no. 3) and bore a central hole to snugly fit one half of the steel pipe nipple (part no. 7). Refer to drawings on page 4.

-

Machine one side of the flange to a 3-inch (7.62 cm) diameter to fit mold body no. 1. (Refer to drawings on page 4)

-

Instructions for Fabrication

- Weld components no. 3 and no. 7 together.

- Chamfer the welded edge on the lathe. (Refer to drawings on page 5)

-

Obtain disc no. 4 and drill a 9/32-inch (7 mm) hole in the center. Refer to drawings on page 6.

-

Drill four holes along the edge of discs 3 and 4, then trim the sides. (See drawings pp. 4-6)

-

Drill four additional 3/16-inch (4.76 mm) holes in disc number 4. (Refer to drawings on page 6)

-

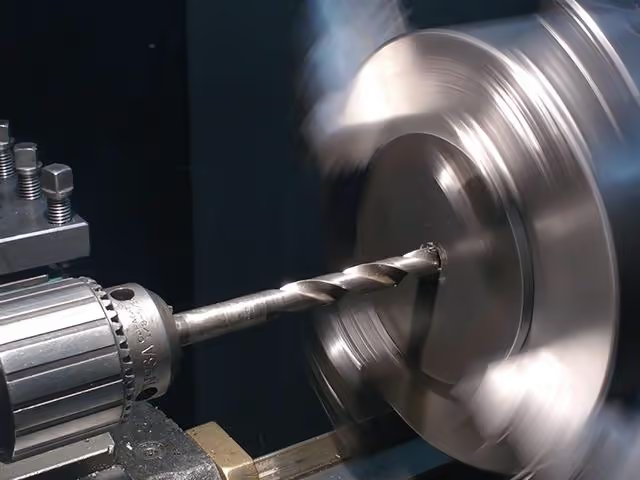

To achieve a curved, smooth, and polished mold cavity surface, provide parts no. 1-2 and the 3D files to a reputable CNC lathe workshop. They can manage various file formats, and the accompanying drawings (pages 7-9) will clarify any uncertainties.

-

Take part no. 5 and trim its corners tangent to a 3-inch (7.6 cm) circle, matching the diameter of part no. 2. Refer to drawings on page 10.

-

Instructions for Sheet Metal Cutting

-

Cutting and Safety Prep:

- Cut part no. 6 from a thin metal sheet.

- Trim the corners to avoid sharp edges.

-

Assembly:

- Center part no. 6 on part no. 5.

- Secure with four nails.

(Refer to drawings on pages 11-12 for guidance)

-

-

Drill a ⅛" (3.175 mm) hole in the center of parts no. 5 and 6. Insert a screw to thread the wood. (Refer to drawings on pages 10-12)

- 13Done!

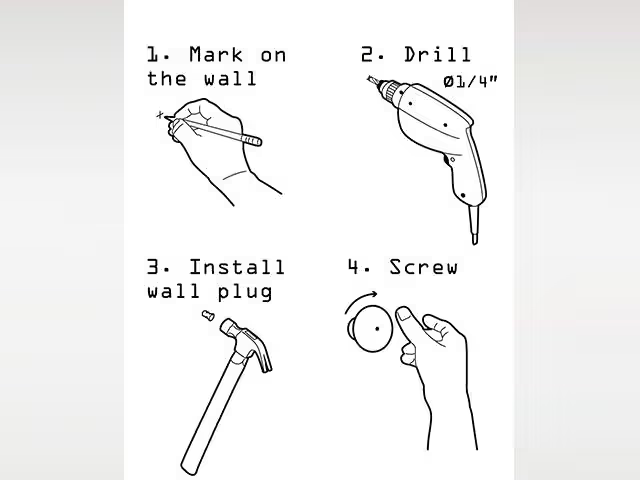

Your Wall Peg mold is complete. Insert a new screw into the wooden mold base before each injection to prevent filling the hole with plastic. If it happens, simply drill it out.

To open the mold, remove the bolts, cut the plastic at the entrance, and separate the mold parts. Unscrew the peg from the wooden section to retrieve your peg.

Allow time for cooling due to the plug's volume and ensure the soft screw is positioned correctly to avoid tilting.

The mold accommodates all types of plastic and allows smooth injection.

-

To install the peg on the wall, drill a hole and secure it with a wall plug.

Tools

- Steel pipe cutter/hacksaw (for cutting pipe nipple) [Page 3]

- Lathe (for machining flange and chamfering edges) [Pages 4–5, 10]

- Welding machine (components no. 3 & 7) [Fabrication Step 1]

- Drill with 9/32", 3/16", and ⅛" bits [Pages 6, 10–12]

- Metal shears/angle grinder (for sheet metal cutting) [Sheet Metal Cutting Section]

Software & Digital Resources

- 3D models and blueprints (linked in tutorial introduction)

- CAD files (for CNC lathe workshop) [Pages 7–9]

- Technical drawings (pages 3–12 for machining guidance)

Hardware Components

- Steel pipe nipple (part no. 7) [Page 3]

- Steel disc (part no. 3) [Page 4]

- CNC-machined flange (parts no. 1–2) [Pages 7–9]

- Discs (no. 4, 5, 6 for assembly) [Pages 6, 10–12]

- Screws and nails (3/16" and ⅛" sizes) [Pages 10–12]

References

Opensource Designs

- Wall Peg mould