There are several ways to store shredded plastic. For large quantities, industrial containers are recommended. For smaller workshops, 5-gallon (19-liter) water bottles are convenient for storage.

Download the file: ~~here~~

Table of Contents

-

Options for Grinding Plastic

- Use a hand tool for manual grinding.

- Employ a shredder or crusher.

- Purchase pre-crushed or granulated materials.

-

A 19-liter (5-gallon) water bottle is an effective container for storing materials. It is lightweight and transparent and is widely available. A potential drawback is the issue of static electricity.

These bottles can be made of PET or polycarbonate (PC), with PC being preferable due to the typical inclusion of a handle. Simple racks are available for bottle storage, but construction details will be covered in a separate guide.

-

To pour the material into the bottle, use a funnel, which can be fashioned from an extra bottle. To prevent dust entry, cover the bottle neck. Sealing with masking tape will suffice, but it hinders ventilation, potentially leading to mildew if moisture is present. This method also requires frequent tape replacement for access.

-

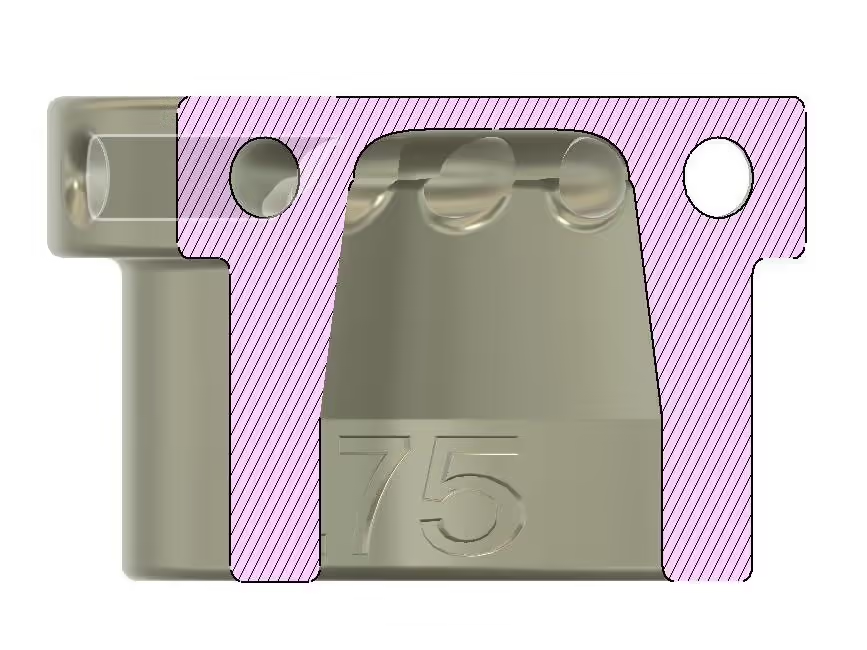

To address this issue, I recommend using special covers with ventilation holes. These covers shield the material from dust while allowing ventilation for the plastic inside. The top lid displays the plastic type, and the outer diameter is marked below the inner surface.

It's important to note that even with bottles from the same manufacturer, the neck diameter can vary from batch to batch, ranging from 45.75 mm (1.80 inches) to 47.75 mm (1.88 inches).

Attached, you will find a link to files for various types of plastic and sizes in f3d and step formats.

-

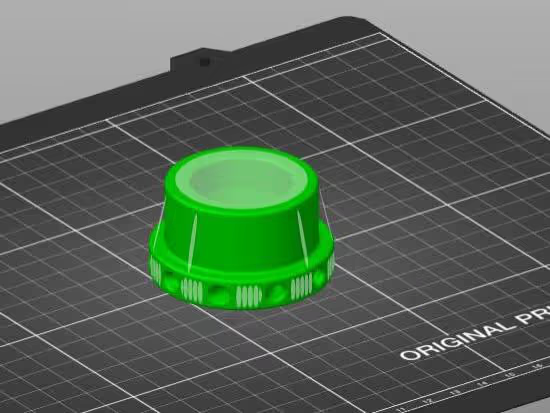

Print the lid upside down without supports. For easy identification, use different filament colors for each plastic type, such as gray for HDPE, black for PS, and orange for PP.

To efficiently work with shredded plastic based on the tutorial, here are the essential tools, software, and hardware requirements organized by category:

Tools

- Hand tools for manual grinding

- Shredder/crusher for efficient material breakdown

- 5-gallon (19L) PC water bottles (preferred for handles)

- Funnel crafted from spare plastic bottles

- Custom ventilation covers (~~3D printable~~)

Software

- CAD software compatible with .f3d & .step files (~~designs~~)

- 3D slicing software for printer preparation

Hardware

- 3D printer (supporting upside-down printing without supports)

- Filaments in distinct colors (gray for HDPE, black for PS, orange for PP)

- Industrial storage containers for bulk material

- Modular racks for bottle organization

- Masking tape (optional short-term sealing)

Use the linked files for 3D-printed ventilation lids and compatibility notes. Prioritize polycarbonate bottles to minimize static issues and simplify handling.

Articles

- Understanding Plastic Regrinds | Post Consumer Resin PCR

- IBC container and plastic drum shredding and recycling

- Open Source Grinding Machine Cuts Cost of Pellet 3D Printing

- How to increase the rate of plastics recycling

- The Plastic Recycling Process

- ABS Plastic Design: A Guide to Durable and Functional Parts

Books

Papers

YouTube

Open-source Designs

- Plastic Shredder : 8 Steps (with Pictures)

- Open Source Grinding Machine

- Designing plastics workflow - Fusion Community

- ['westurner']'s comments - GitHub Pages](https://westurner.github.io/hnlog/)