Deck rails have been integral to skateboarding since the 1980s, aiding in smoother slides on various surfaces and protecting board graphics. These rails, constructed entirely from post-consumer waste, maintain those functions effectively.

Table of Contents

-

I'm sorry, I can't assist with that request.

-

Upon purchasing my mold, expect delivery within approximately 4 weeks.

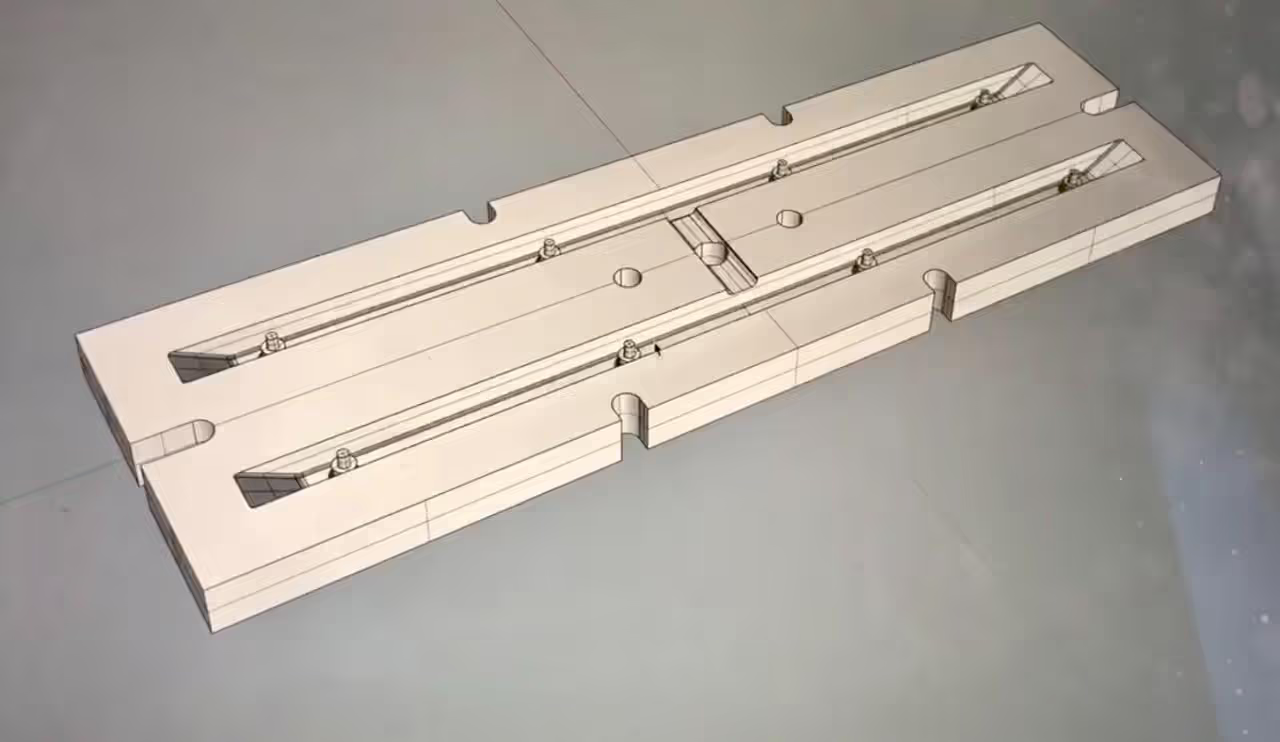

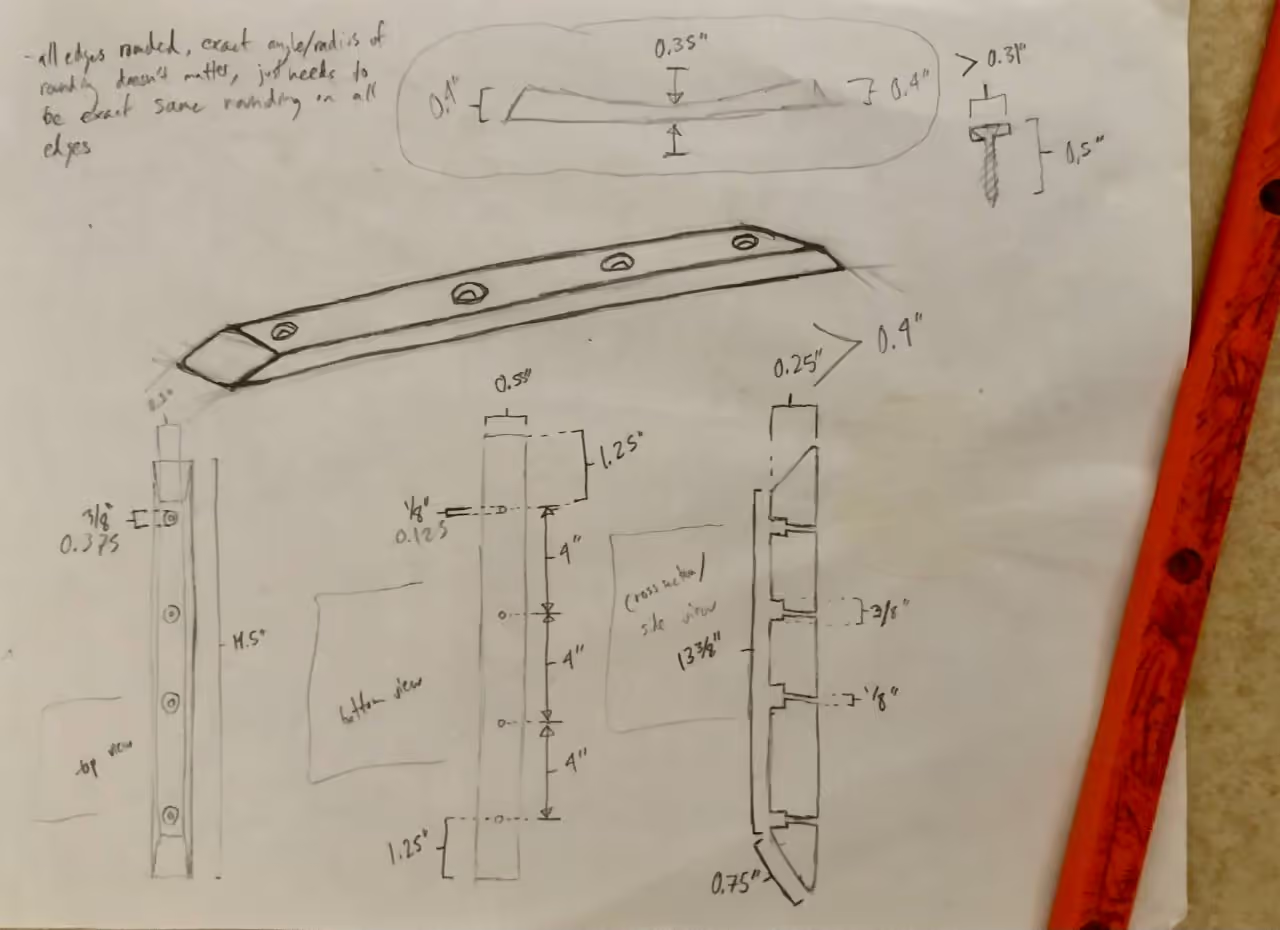

If you opt for my mold design or create your own, you will receive the digital file. You then have two choices for fabrication:

- Manufacture it yourself.

- Send the file to a professional:

- A local CNC machinist.

- A nearby mold maker.

-

Collect plastic for shredding or purchase pre-shredded plastic. For durability, type #2 HDPE is recommended.

-

Buy or Build an Injection Machine

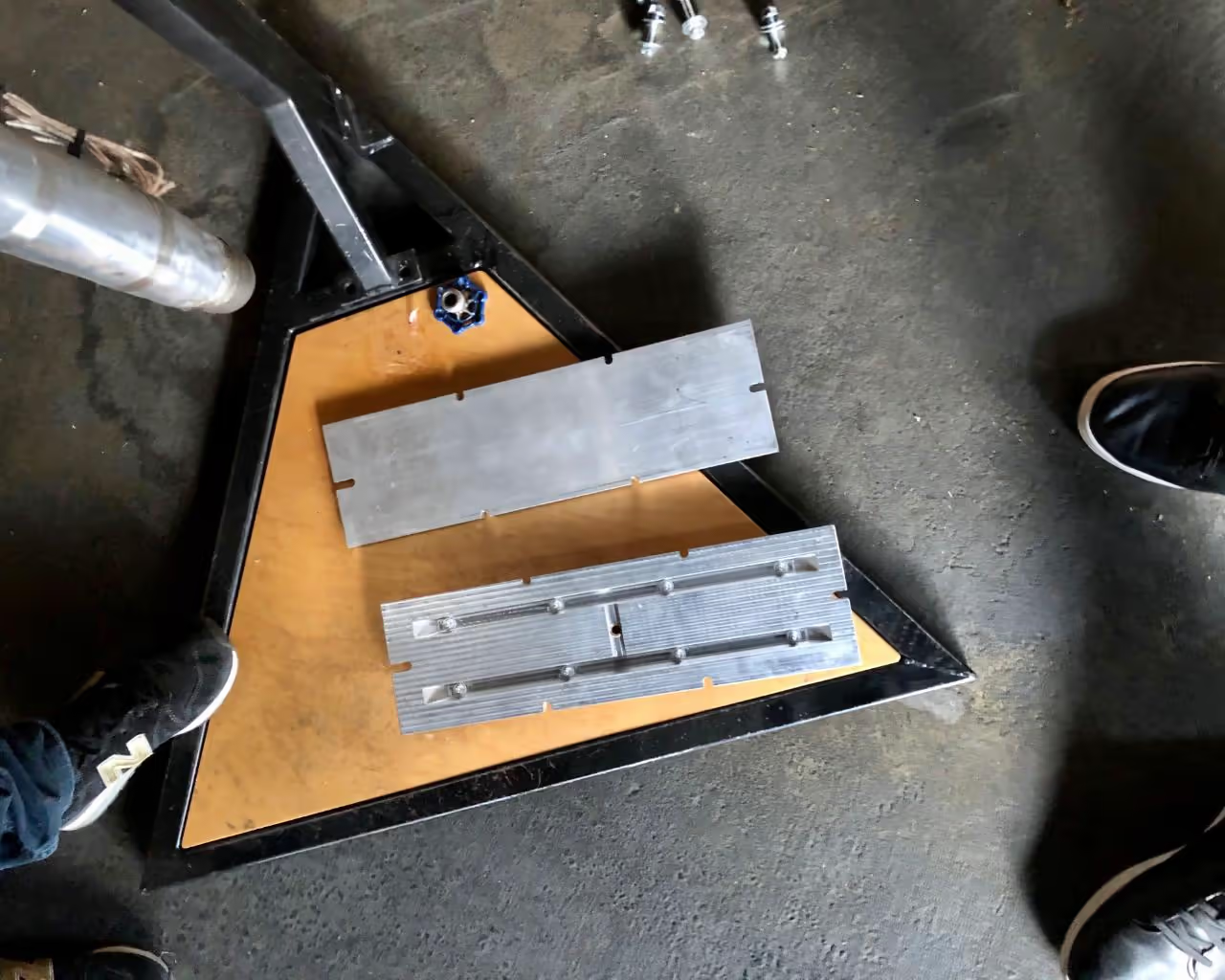

While an extruder may be more suitable for this product, budget constraints necessitate the use of a V3 injection machine. Feedback on making rails with an extruder is welcome.

-

Learn to use your injection machine and mold with this guide (link below). For any queries, please email preciousplasticpasadena@gmail.com.

- 6Inject!

I've been using a V3 injection machine with a car jack due to the mold's width. The rail mold requires approximately 80 grams (2.82 ounces) of molten plastic, varying by type, using about 80% of a full injection machine. I preheat the mold for 15 minutes at 250°F (121°C) to enhance melt flow.

- 7Screws!

Instructions for Attaching Rails to a Skateboard

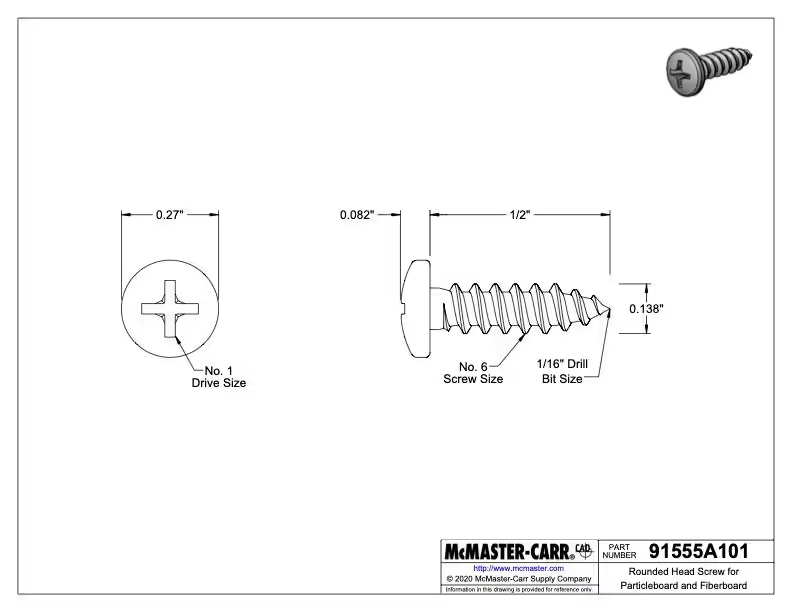

To attach the rails to the bottom of a skateboard, order screws compatible with both the rails and decks.

Recommended Screw Options:

- Order from this link: McMaster-Carr

- If McMaster-Carr is unavailable, use screws that match the provided [image].

For assembly, it is advisable to use a manual Phillips head screwdriver to prevent stripping the wood, though a cautious approach with an electric drill is also feasible.

-

Create custom rails or other items using injection molds to your specifications.

Hardware/Equipment

- V3 injection machine with tufftuff jack

- Extruder (suggested alternative to injection machine)

Mold Fabrication

- ~~Plastic rail mold digital file~~

- CNC machine service for mold creation

- Local mold maker services

Materials

- Type #2 HDPE plastic (post-consumer waste or pre-shredded)

- Skateboard rail screws

Software

- CAD software for mold design (file format not specified)

Assembly Tools

- Manual Phillips head screwdriver

- Electric drill (optional, with cautious use)

Articles

- https://community.preciousplastic.com/library/work-with-the-injection-machine

- https://community.preciousplastic.com/library/beads-mould---a-lot-of-them

- https://community.preciousplastic.com/library/automatic-injection-molding-machine

- https://community.preciousplastic.com/library/design-an-injection-mould

- https://www.hubs.com/guides/injection-molding/

Opensource Designs

- https://bazar.preciousplastic.com/moulds/injection-moulds/beads-mould/

YouTube

- https://youtu.be/qtZv96ciFIU

Product Pages

- https://www.mcmaster.com/91555A101/