Plastic sheets made with a sheet press do not need to be square.

This guide explains how to create an octagonal mold for producing octagonal plastic sheets. The same techniques can be used to create molds of other polygonal shapes, such as triangles and hexagons.

For inquiries or suggestions about the mold, please refer to our contact information.

Table of Contents

-

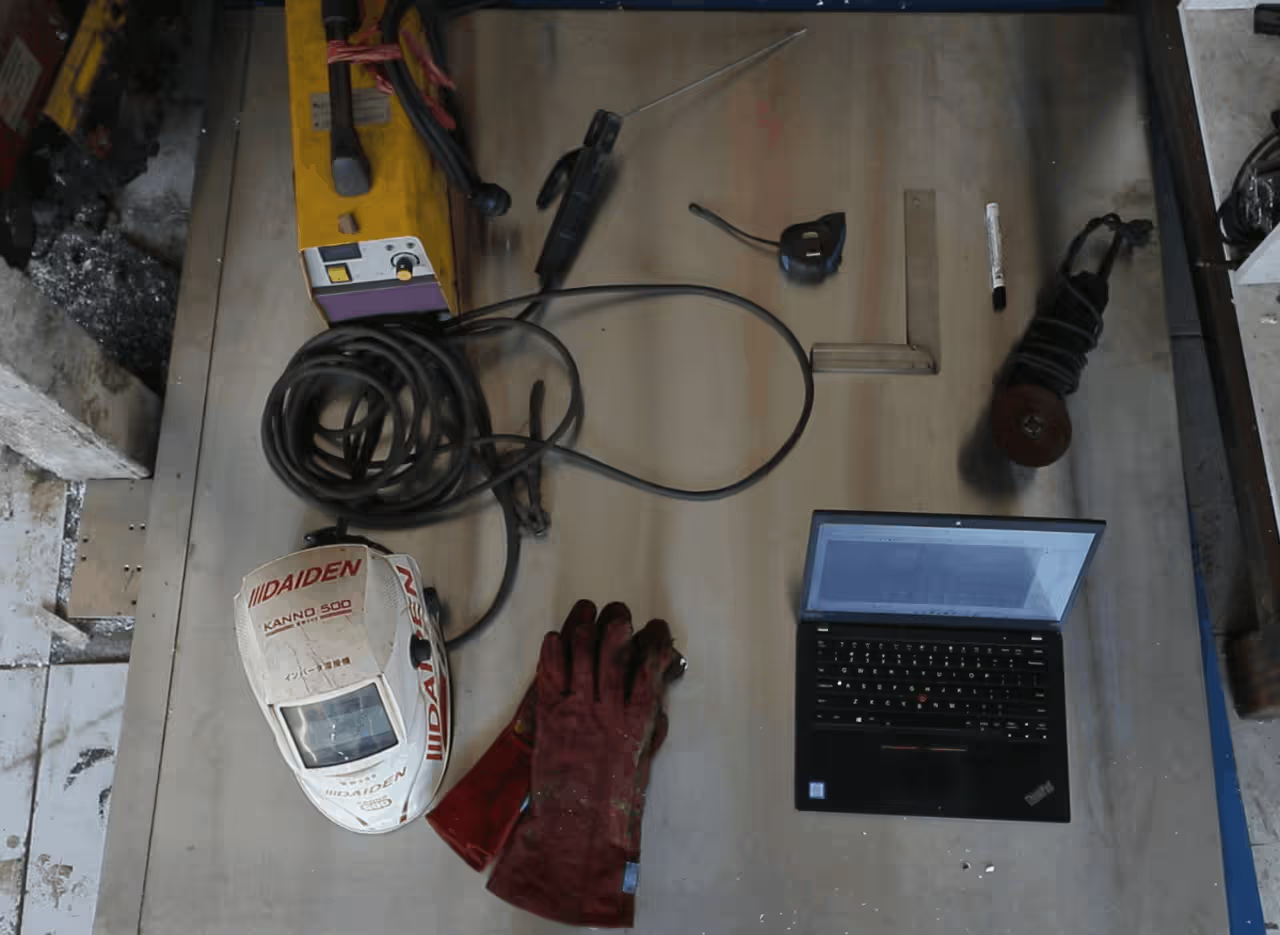

Tools:

- Sheet press set

- Angle grinder

- Welding tools and materials

- Jigsaw

- Sander (for product finishing)

- Safety gear: welding helmet, safety glasses, mask

- Marker

- Ruler

Computer with drafting/drawing software

Materials:

- Steel for mold: 0.78x0.78 in galvanized steel (standard size = 19.7 ft)

- Clean, sorted plastic of chosen types

- 2Draw

Polygon Drawing Tutorial

-

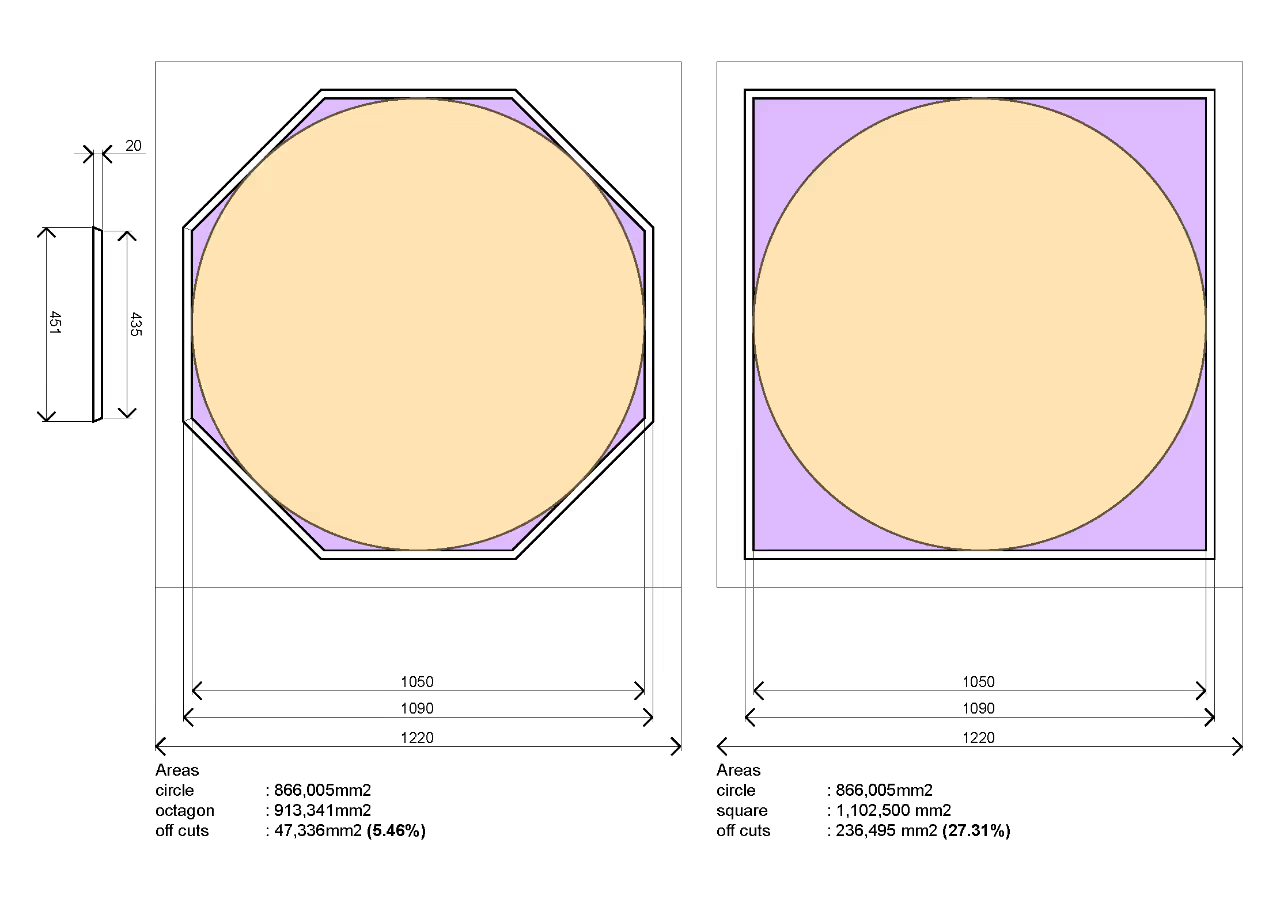

Drawing the Polygon:

- Use any drafting software to create a polygon. This provides precise dimensions for each side. A reference drawing is available in the provided drive link.

-

Work Area Measurement:

- Measure your sheet press work area.

- Offset the measured area by 2 inches (5 cm) inward to account for space needed around the mold.

-

Polygon Adjustment:

- Adjust polygon dimensions according to your sheet press machine's capacity.

- Offset by 0.8 inches (2 cm) inward for the thickness of galvanized steel.

-

Mold Dimension Measurement:

- Derive mold dimensions from your drawing.

- Utilize this drawing for calculating the plastic needed for sheet production.

-

- 3Cut

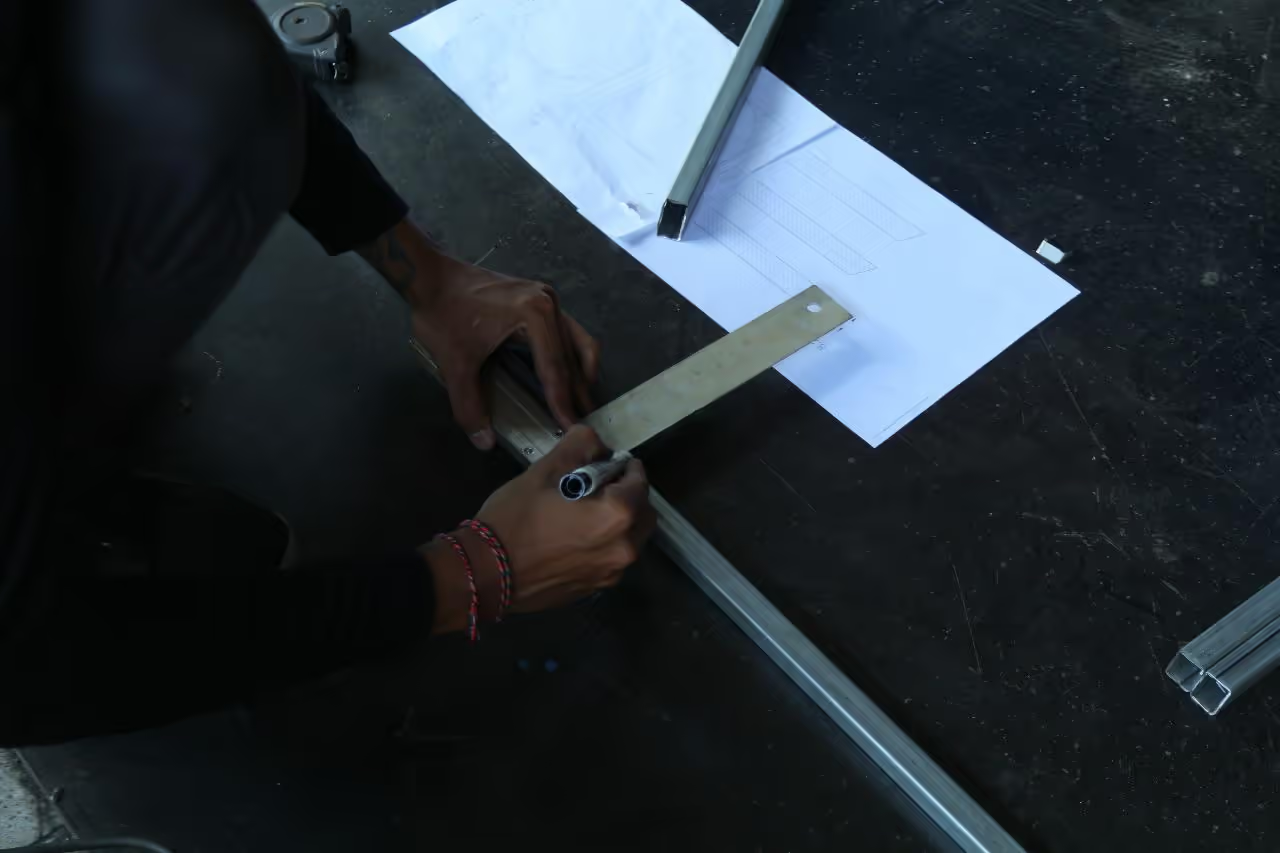

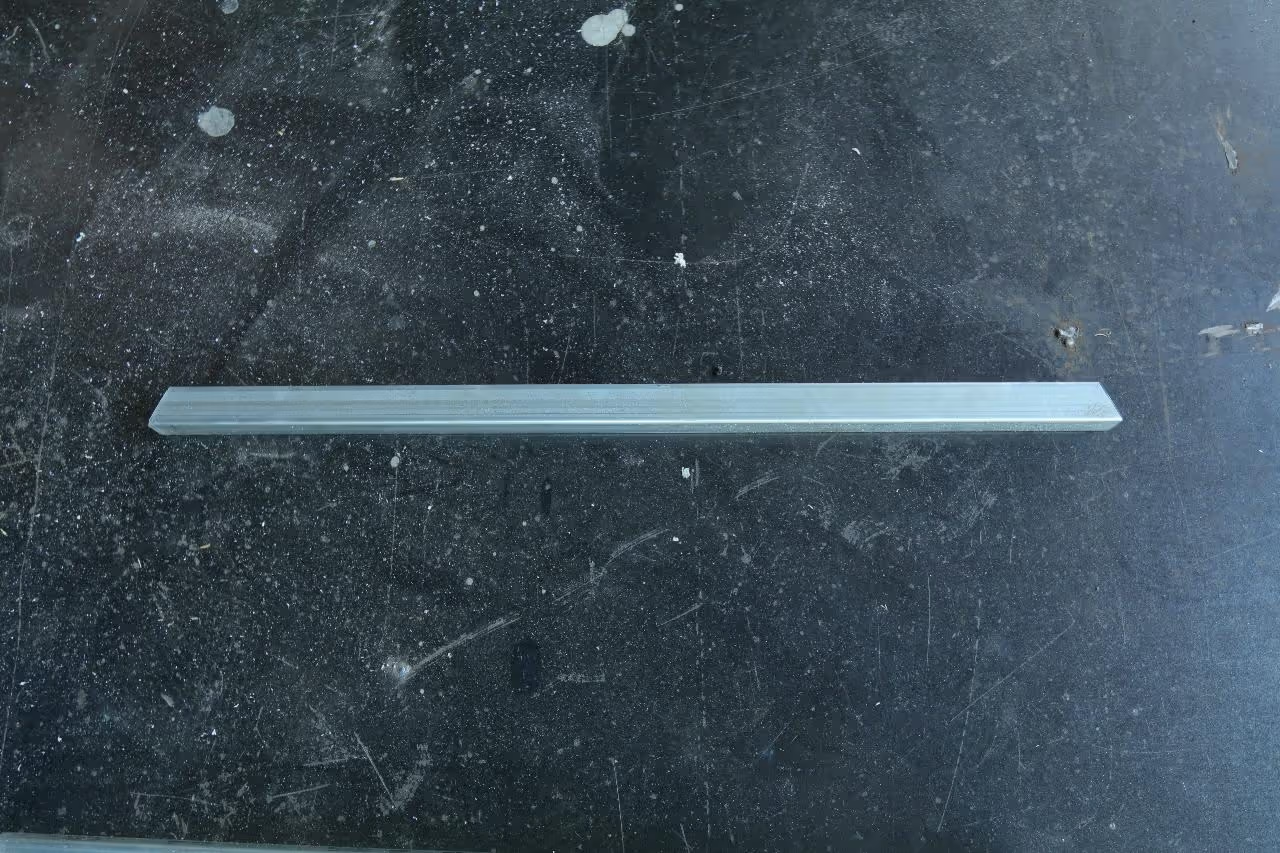

After determining measurements, cut the 20mm (0.79 inches) hollow galvanized steel with an angle grinder.

Use an erasable marker for precision. Cut using the angle grinder. Draw a 1:1 template of your sheets with a whiteboard marker to ensure alignment of angles and dimensions, and adjust as needed.

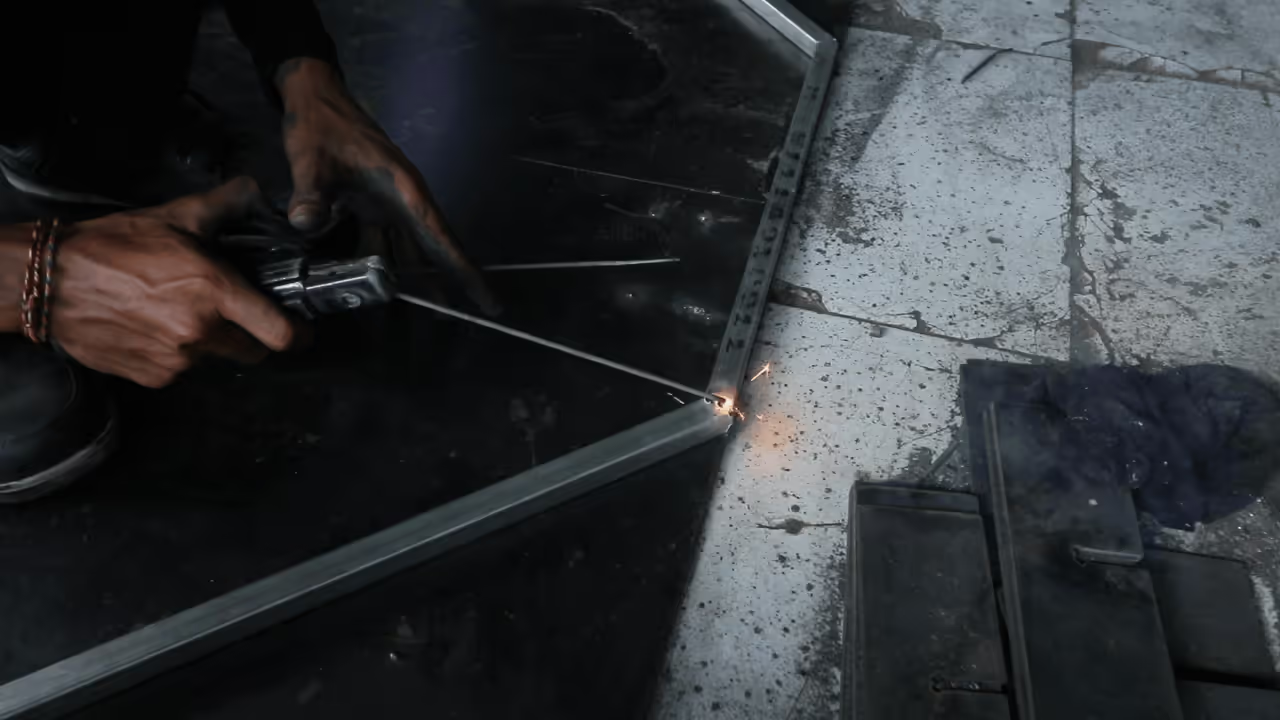

- 4Weld

With a whiteboard marker, draw a full-scale template of your sheets to ensure angles and dimensions align, adjusting as necessary.

Weld the sides to connect the ends, forming polygonal sheets.

-

Grind excess welding material with an angle grinder. This ensures the mold is flat against the sheets, preventing damage to the steel plate and leakage of plastic.

-

Polygonal Sheet Creation Guide

Calculate the required plastic based on the polygon's area.

Refer to the sheet press tutorial for detailed instructions: YouTube Video.

Tools

- Sheet press set (YouTube tutorial)

- Angle grinder

- Welding tools and materials

- Jigsaw

- Sander (for finishing)

Software

- Drafting/drawing software (e.g., AutoCAD)

Hardware

- 20mm hollow galvanized steel (0.78x0.78 in)

- Clean, sorted plastic sheets

Articles

- Plastic Sheet Press Process

- Literature Review: Open Source Waste Plastic Sheet Press

- Plastic Casting Process Guide

Papers

YouTube

Opensource Designs

- Polygonal Mould Guide

- ~~Sheetpress Construction Guide~~

- Sheetpress Workspace Setup