Plastic sheets created with a sheet press need not be square.

Here, we demonstrate how to make an octagonal mold for octagonal plastic sheets. These techniques can be used to create any polygonal mold, such as triangular or hexagonal.

For further guidance, feel free to contact us with any questions or suggestions regarding the mold.

Table of Contents

-

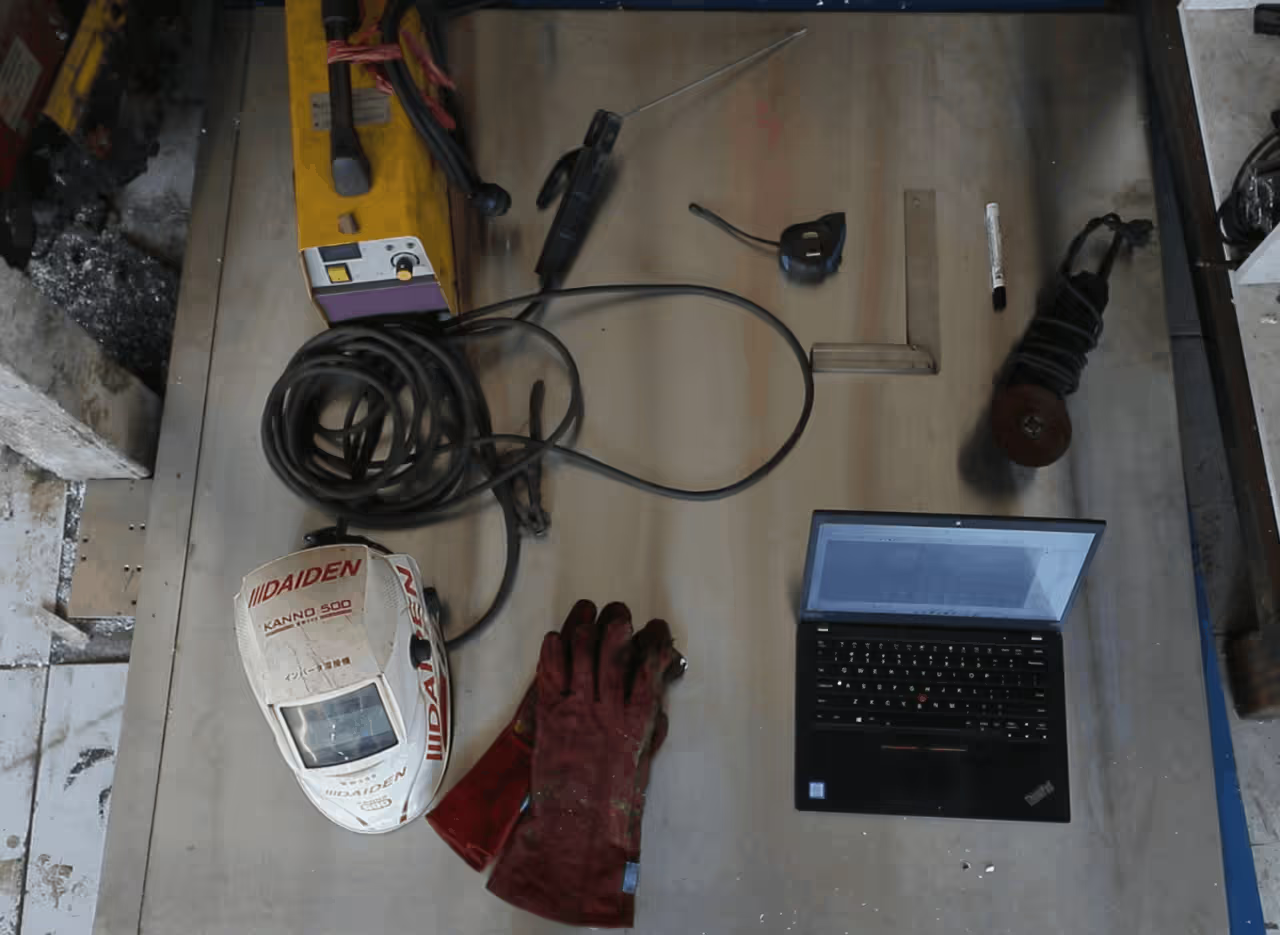

Tools

-

Sheet press set

-

Angle grinder

-

Welding tools and materials

-

Jigsaw

-

Sander (for product finishing)

-

Safety gear: welding helmet, safety glasses, mask

-

Marker

-

Ruler

-

Computer with drafting/drawing software

Materials

- Steel for mold: 0.79 x 0.79 inches (2x2 cm) galvanized steel (standard size = 19.7 ft)

- Clean, sorted plastic, type optional

-

- 2Draw

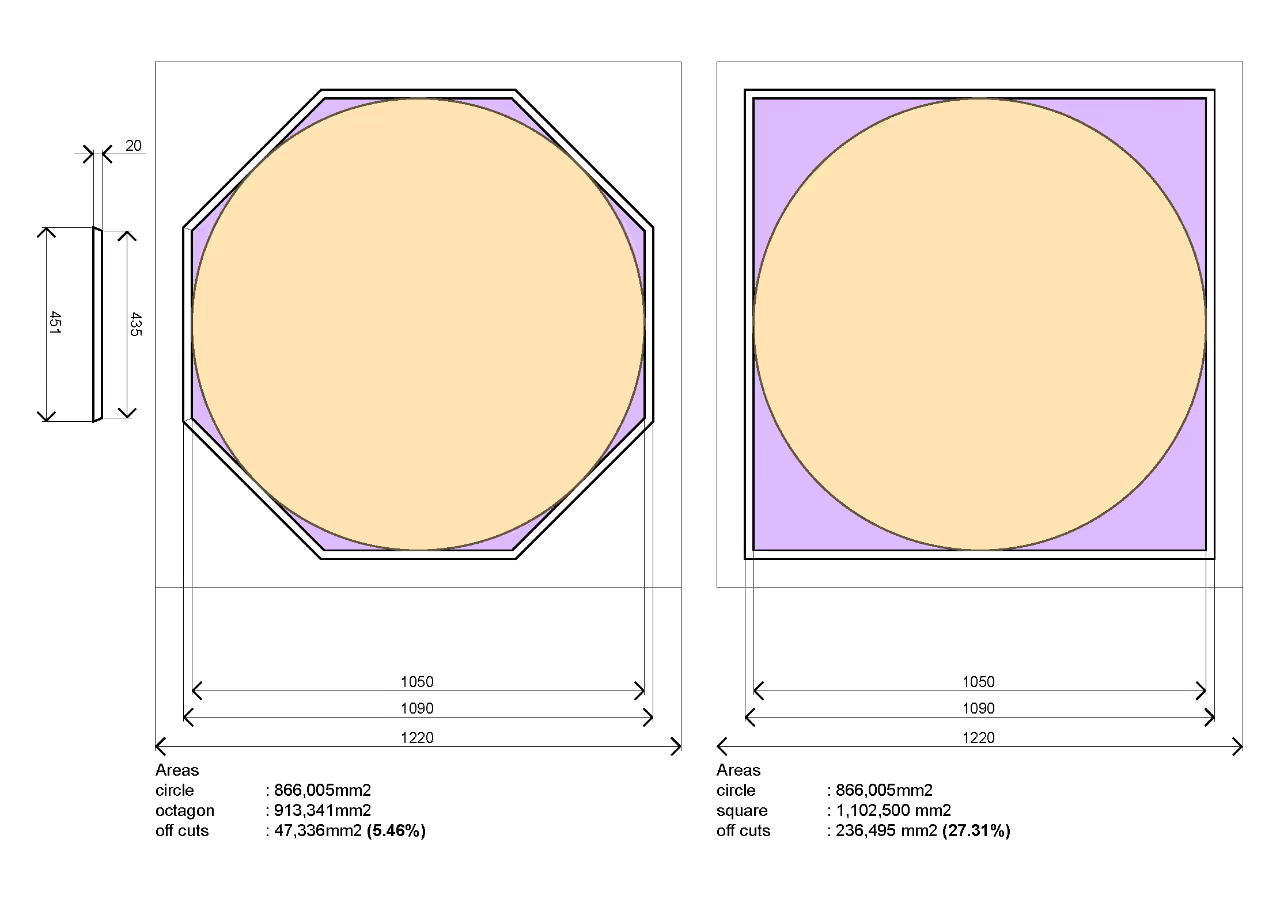

Draw the polygon in your preferred drafting software to obtain precise dimensions for each side.

Measure your sheet press work area.

Offset by 2 inches (5 cm) inward for space around the mold.

Design the polygon based on your machine's capacity.

Offset by 0.8 inches (2 cm) inward for the steel thickness.

Use the drawing to measure the mold dimensions. This will aid in calculating the plastic required for sheet production.

- 3Cut

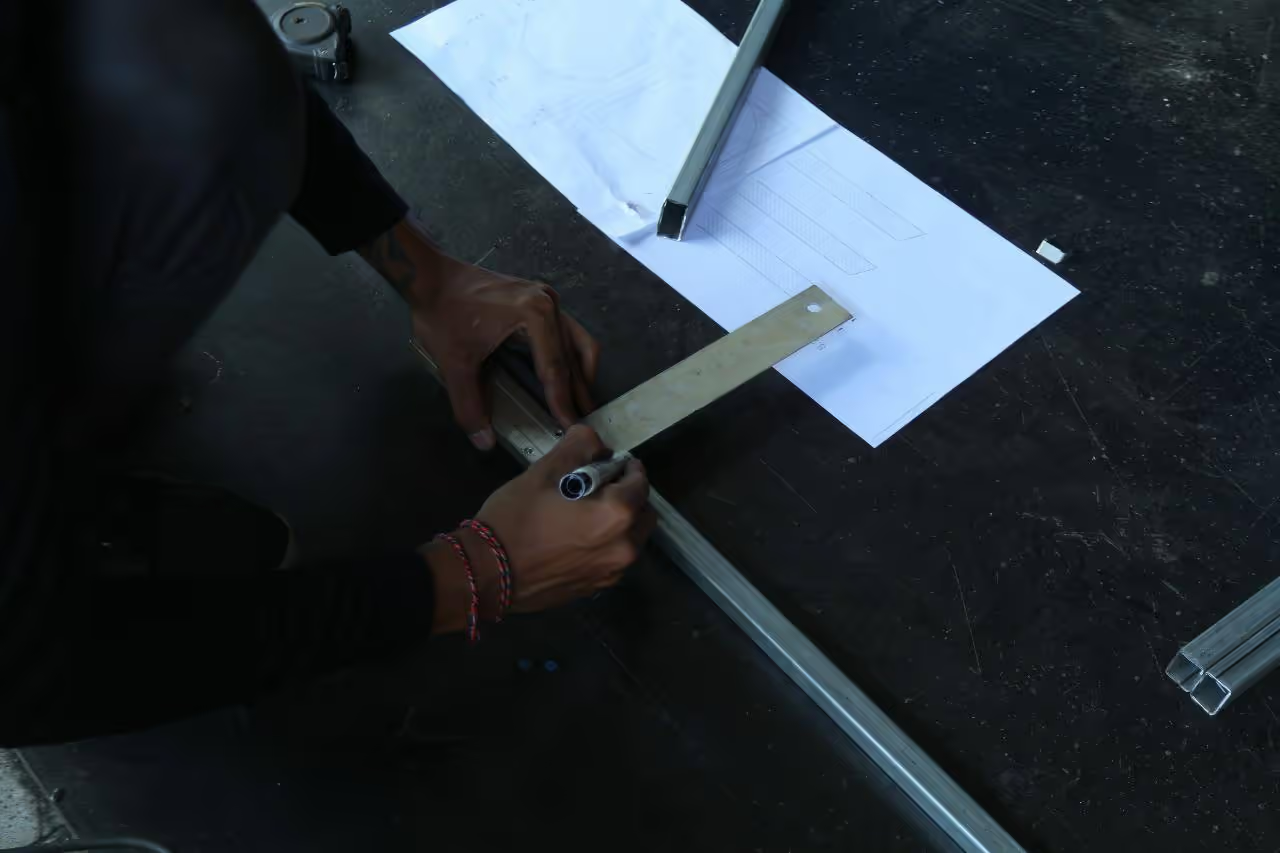

After outlining and measuring, use an angle grinder to cut the 20mm (0.79 inches) hollow galvanized steel to the specified size.

Mark dimensions using an erasable marker for accuracy. Employ an angle grinder for cutting. Use a whiteboard marker to draw a 1:1 template of your sheets to align angles and dimensions properly, adjusting as necessary.

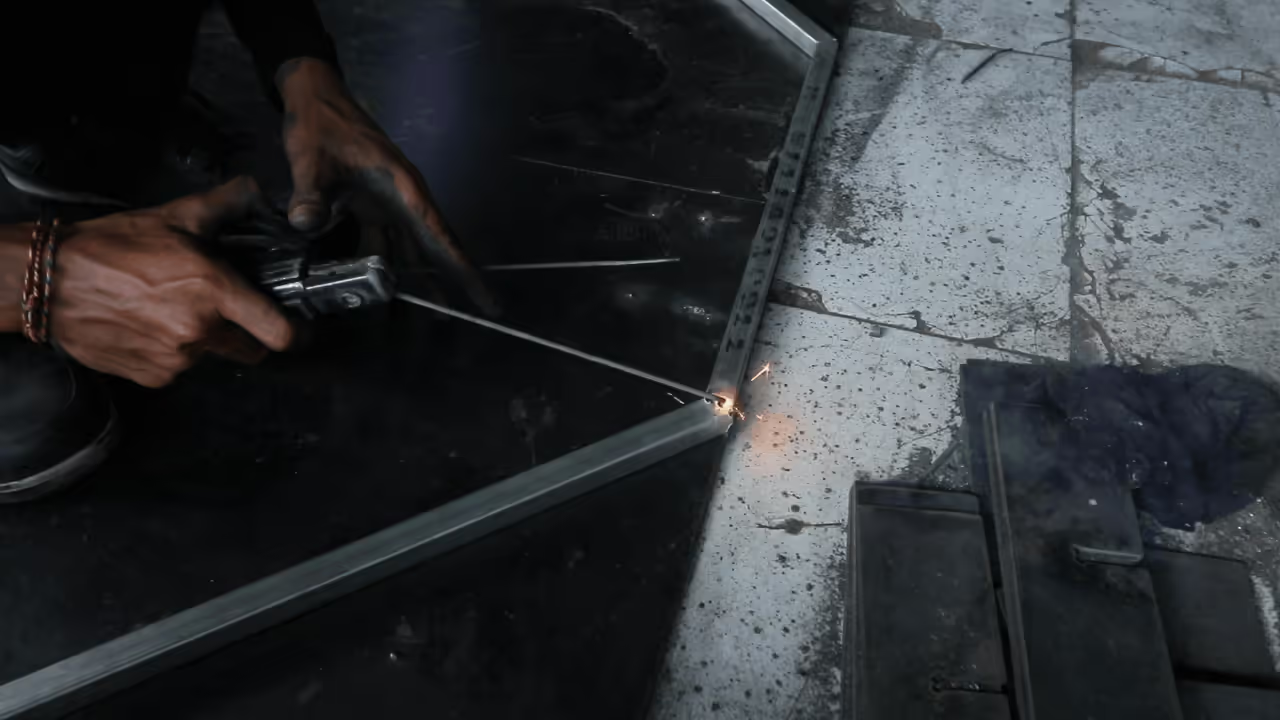

- 4Weld

Using a whiteboard marker, draw a full-scale template of your sheets to verify and adjust angles and dimensions as necessary.

Weld all sides to join the ends and form your polygonal sheets.

-

Use an angle grinder to smooth excess welding material. This is essential to ensure the mold lies flat against the sheets, preventing damage and preventing plastic from leaking if the surface is uneven.

-

How to Make a Polygonal Sheet

Calculate the area of your polygon from the drawing to determine the required plastic amount.

Refer to the sheet press tutorial for detailed instructions: YouTube Video

Feel free to share your experience with us.

Sincerely,

Wedoo Team

Creating an octagonal mold for plastic sheets using a sheet press requires specific tools, software, and materials. Below is a structured breakdown of the essential components needed for the project.

Tools

- Sheet press set

- Angle grinder (cutting and smoothing)

- Welding tools and materials (assembly)

- Sander (product finishing)

- Safety gear: welding helmet, safety glasses, mask

Software

- Drafting/drawing software (dimension planning)

Hardware

- Galvanized steel (0.79 x 0.79 inches, 19.7-ft standard length)

- Clean, sorted plastic (type flexible)

- Marker and ruler (measurement marking)

For detailed instructions, refer to the sheet press tutorial video[1].

Articles

- Polygonal mould for sheet press - [filtered] Academy

- Custom Silicone Octagon Mold - ZSR Consumer Silicone Products

- Polygon Press Mold For Lab - Kintek Solution

- Octagon Mold - Tomric Systems, Inc.

YouTube

- How We Made A TINY Injection Molding Machine - YouTube

- How To Make A Plastic Sheet With A Sheetpress?! | By Wedoo

Papers

Books

Opensource Designs

- Polygonal mould for sheet press - [filtered] Academy