The PET MINI Skateboard is an open-source electric skateboard designed for efficient urban transportation. It aims to enhance your commuting experience by providing a swift, convenient last-mile travel solution.

For further inquiries or to engage with the maker community in Portugal, please contact us.

Table of Contents

- 1Story

The PET MINI (Personal Electric Transport) project highlights participatory design approaches.

Utilizing Open Design, it allows for easy prototyping and global distribution while supporting local manufacturing and problem-solving.

The initial prototypes used plastic PP sheets provided by [filtered] HQ, which were machined into skateboard decks using a CNC router. Mechanical parts were 3D printed at a local Fab Lab, VIVALab. This process can be replicated at any of the 2,000 Fab Labs worldwide.

-

Certainly. Here's the refined text:

DIY electric skateboards involve various specifications and parts selection. The components listed here enable a top speed of 22 mph (35 km/h) and a range of 22 miles (36 km):

- 1x 10s BESTECH BMS 60A Battery Pack 12s2p (10s3p)

- 1x BUNDLE HTD 5M 53 teeth Belt 10.4 inches (265mm)

- 1x Electric Skateboard Speed Controller, Open Source VESC

- 1x Eskating PRO Motors 6374 190Kv

- 2x Caliber II Trucks 50° 10 inches

- 4x Kegel 80mm Wheels

- 8x ABEC 608 Bearings

- 1x 2.4GHz Remote

- 1x 16T Motor Pulley (8mm or 10mm)

- 1x 3D Printed Wheel Gear Pulley and Motor Mount

- 1x Skateboard Hardware Set - 1 inch

- 2x 1/2 inch Rubber Riser Pads

- 1x 3 feet (1m) of 0.04 inch (1mm) Rubber Window Insulation

-

Instructions

-

Create a 0.79-inch (20mm) Sheet:

Use the sheet press. -

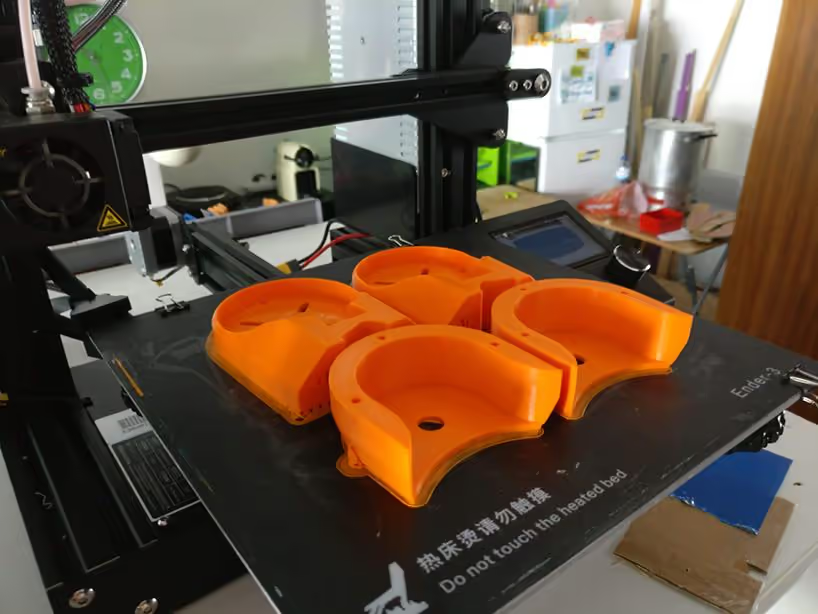

3D Print Components:

-

Armadillo Electronic Case:

- Material: PLA

- Infill: 25-45%

- Layer Height: 0.012 inches (0.3mm)

-

Motor Mount:

- Material: ABS

- Infill: <45%

- Layer Height: 0.008 inches (0.2mm)

-

Wheel Gear Pulley:

- Material: PC-ABS or Carbon Fiber

- Infill: <45%

- Layer Height: 0.008 inches (0.2mm)

-

-

CNC Milling:

Use the 3D model of the deck on a 0.79-inch (20mm) plastic sheet. Parameters depend on the CNC equipment at your local facility.

-

-

This tutorial provides guidance on programming and assembling electronics.

Electronics Assembly: YouTube Tutorial

-

After assembling all components, programming the electronics, and adding rubber insulation to the electronics case, you are ready to test your electric skateboard.

If you have any questions or wish to engage with the community in Portugal, please contact us.

Visit: vivalabporto.com makerisland.io

Share your results: @vivalabporto #vivalabporto

The PET MINI Skateboard project combines open-source design with local manufacturing. Below is a concise breakdown of required tools, software, and hardware, optimized for replication in facilities like Porto’s VIVALab.

Tools

- Sheet press (for 20mm plastic sheet creation)

- CNC CNC Router (deck milling from PP sheets)

- 3D printer (PLA/ABS/PC-ABS parts)

- Local Fab Lab (VIVALab for 3D printing)

- CNC machining facility (global Fab Lab network)

Software

- Open Source VESC (programmable speed controller)

- VESC Tool (configuration and firmware updates)

- CNC machining software (device-specific parameters)

- CAD/CAM software (deck design and toolpath generation)

Hardware

- 10s BESTECH BMS 60A Battery Pack (12s2p/10s3p) [1][2]

- Eskating PRO 6374 190Kv Motors [1]

- Caliber II 50° Trucks (10-inch) [1]

- Kegel 80mm Wheels (with ABEC 608 bearings) [1]

- 3D-printed components (VIVALab or local Fab Lab)

For community support or local collaboration in Portugal, visit VIVALab Porto or Maker Island.