Since 2016, NoPlasticSunday has been developing machinery for plastic processing in Korea. In April 2022, we released the Air Press Injector v1 designs and manuals for free.

Contributors:

- PRAG Manufacture Team: Lee Cohni, Choi Hyeontaek, Jin Yonghun

- PRAG Brand Team: Cho Minjung, Kim Sanga, Seo Junhee

Project Roles:

- Direction: Cohni, Minjung

- Machine Development: Cohni, Hyeontaek, Yonghun

- Drawing Creation: Yonghun

- Poster Design: Sanga

- Content Editing: Junhee

- Translation: Junhee (English), Sanga (Japanese)

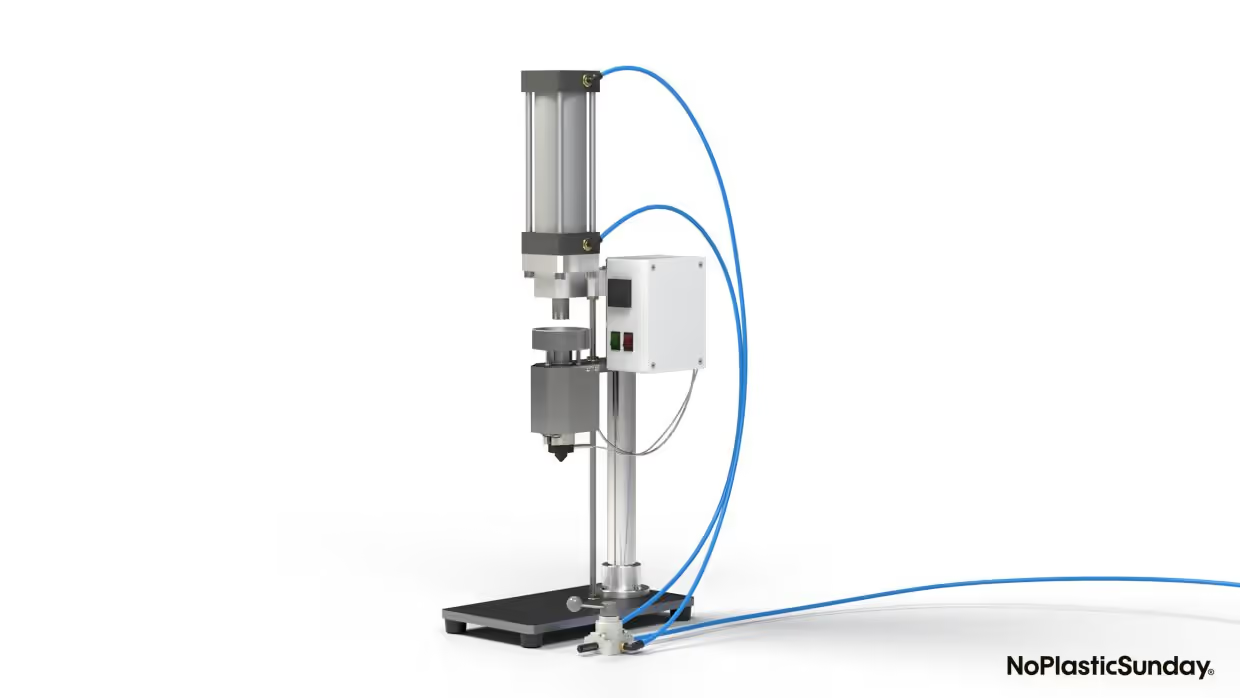

Air Press Injector Open Source by NoPlasticSunday®

Table of Contents

-

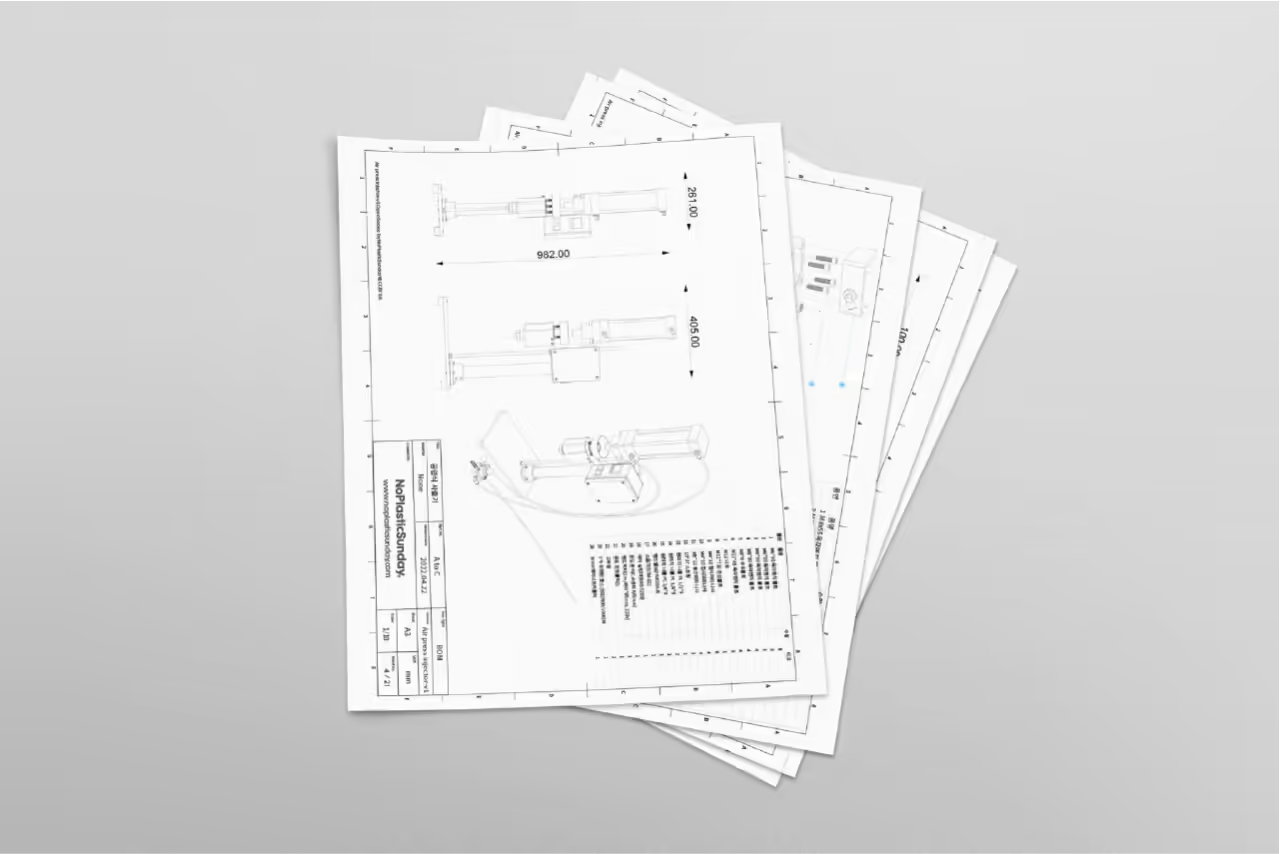

First, click on the download link above to access the machine files. Available PDFs are in Korean, English, and Japanese, containing explanations and mechanical drawings.

-

Air Press Injector v1: Construction Guide

Build your own Air Press Injector v1 by following the provided drawings. Use and share this open-source design freely. Any enhancements to the design are encouraged.

We invite you to share your experiences. What challenges did you encounter during construction, and how did you address them? If you have innovative ideas to enhance functionality, please share your results and methods. Collaborative problem-solving can simplify obstacles.

-

Have you completed building the machines?

Please consult the Air Press Injection Machine manual for setup and operational instructions.

Plastics offer convenience but can also become a threat. Let's work together to build an efficient recycling system.

Tools

- Basic machining tools (drills, saws, clamps)

- Metalworking equipment (welder, grinder)

- Measurement tools (calipers, rulers)

- Pneumatic system components (air compressor, hoses)

- Fastening hardware (screws, bolts, nuts)

Software

- PDF viewer ~~Download Link~~ (Korean/English/Japanese manuals)[1]

- CAD software (for viewing/modifying mechanical drawings)*

- Translation tools (optional for multilingual collaboration)*

- Document editing software (for content adaptation)*

*Specific software not explicitly stated; recommended based on project needs

Hardware

- Structural metal frames (aluminum/steel)

- Injection molding components (nozzles, heating elements)

- Pneumatic valves and actuators

- Pressure regulation systems

- Safety interlocks/switches

Collaboration Tools

- NoPlasticSunday® forum/community platform*

- File-sharing service (for design updates)*

- Version control system (for iterative improvements)*

*Implied by open-source sharing philosophy[1]

Safety Equipment

- Heat-resistant gloves

- Protective eyewear

- Respiratory masks (for microplastic handling)

- Emergency stop mechanisms

- Pressure release valves

[1] Source: NoPlasticSunday® Air Press Injector v1 documentation

References

Open-source Designs

Papers

Articles

- [filtered] Collection Point Setup Guide