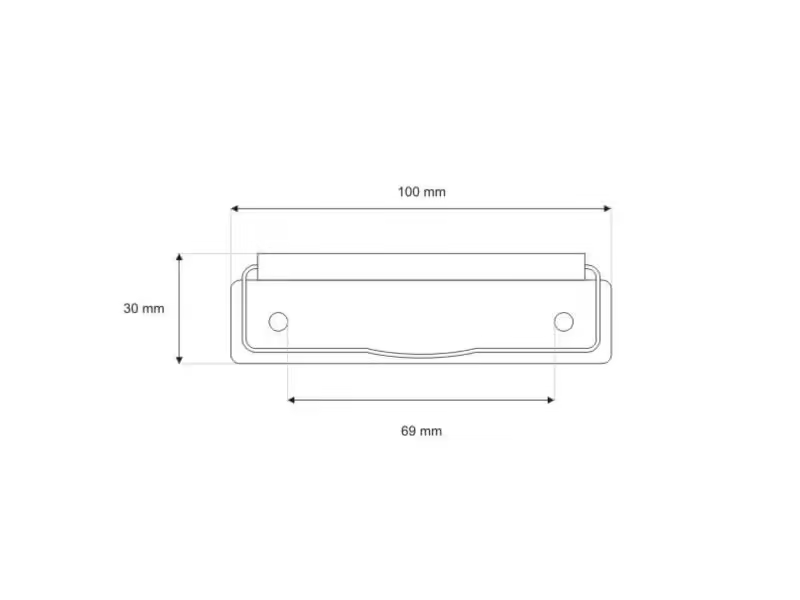

Create a bespoke clipboard from repurposed plastic. Board dimensions: 12.4x9.1 inches (315x230 mm) with a thickness of 0.2 inches (5 mm) and four corner radii of 0.3 inches (R8).

Table of Contents

-

I provide 3D data and blueprints for personal use. Material: steel, thickness: 5 mm (0.2 inches).

Recommended mold fasteners:

- M6x45 (1.77 inches) bolts (minimum 4)

- M6 washers

- M6 nuts

-

Clipboard Production Guide

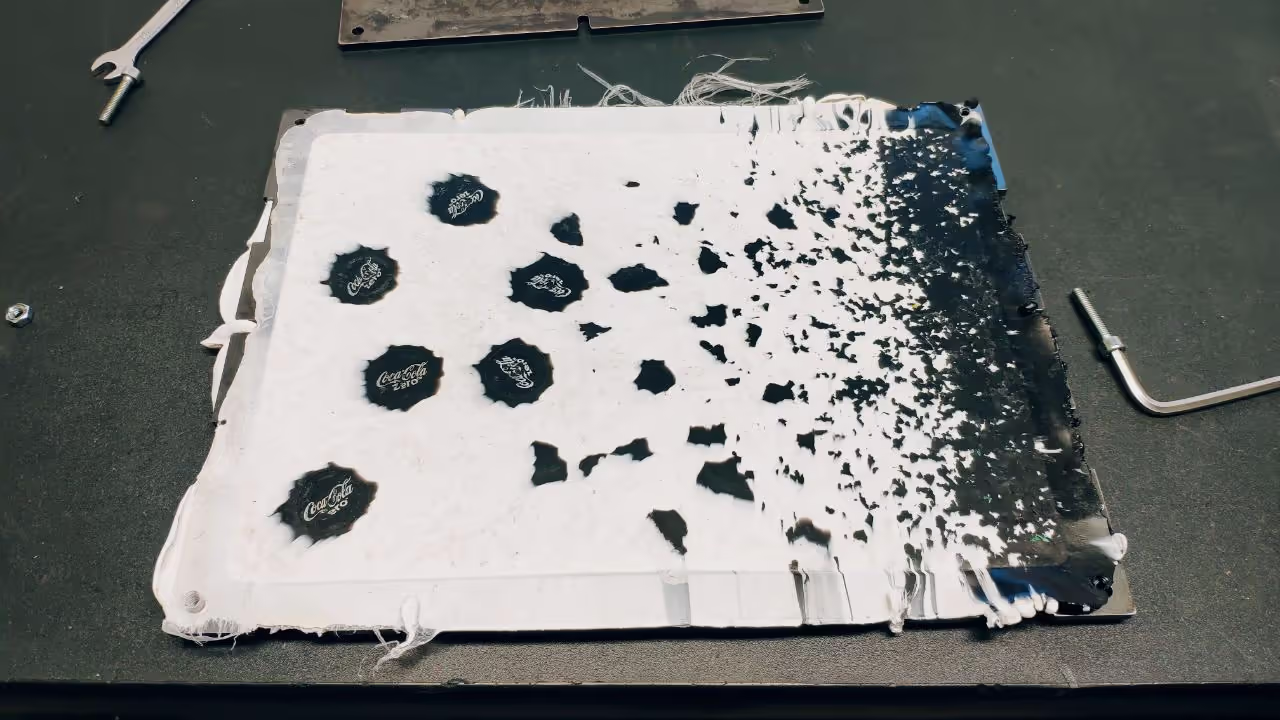

I have tested HDPE, PP, and PLA with satisfactory outcomes. Experiment with various colors and bottle cap designs. You will need approximately 320-350 grams (11.3-12.3 ounces) per clipboard.

Before experimenting with new materials, document the quantity used for reference in future production.

Ensure the mold is free of impurities, dust, or residual plastic from prior use; smooth sandpaper is effective for this task. Apply a mold release agent or oil to prevent sticking, ensuring the oil's smoke point exceeds 230°C (446°F).

For further details on oil smoke points, consult Wikipedia.

-

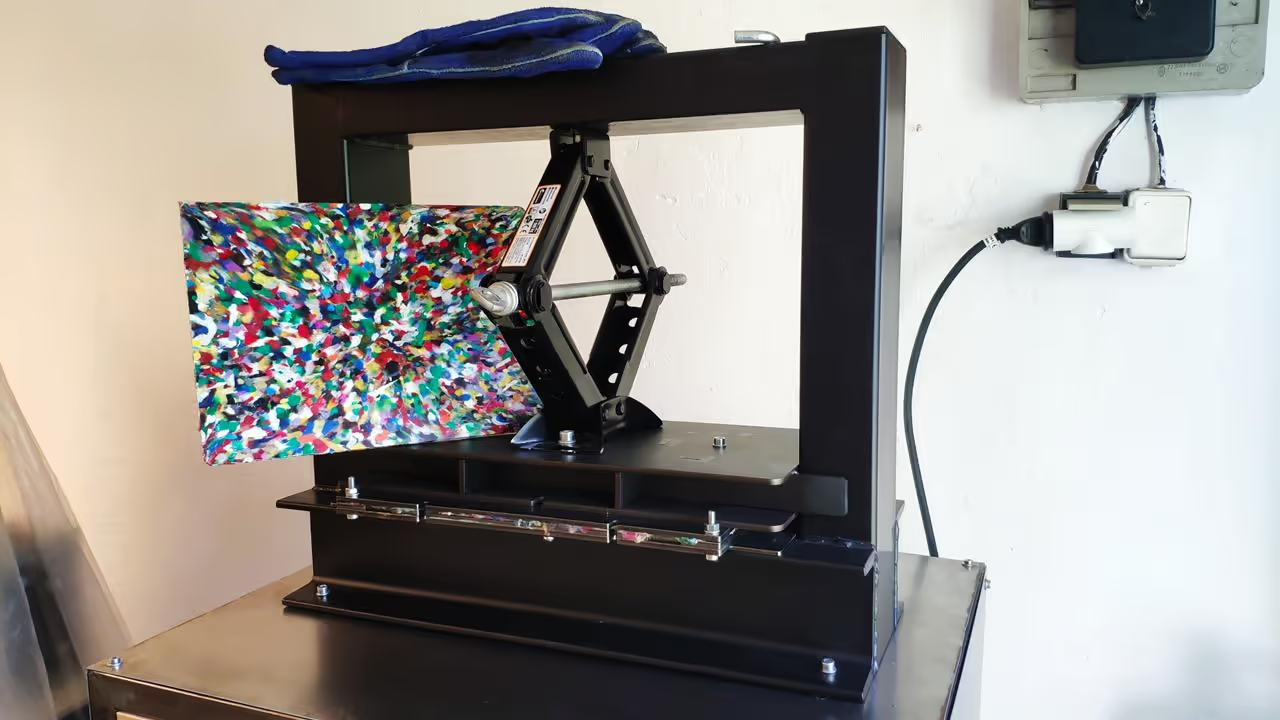

I use an IKEA Görlig electric oven. Adjust the temperature according to the material type. For HDPE and PP, I set the temperature to 225°C (437°F). Place the mold in the oven for 35 minutes and set a timer.

Attention: Use heat-resistant gloves when handling the mold from the oven.

After baking, press the mold. The cooling process takes 20-30 minutes. Opening the mold earlier may risk deformation.

-

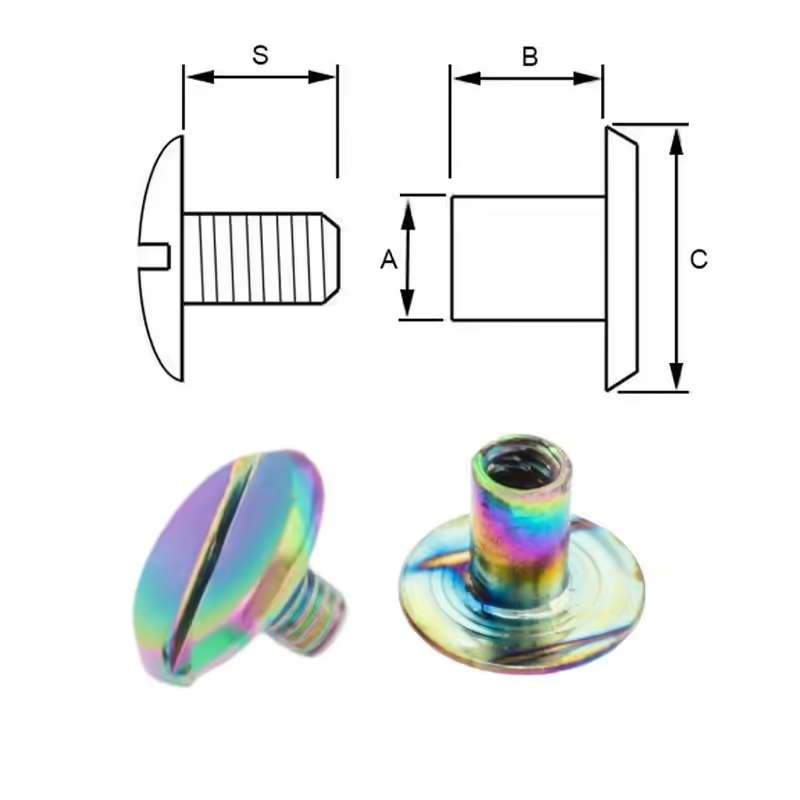

Trim the edges with a knife. Sand the surface if needed. Drill two M4 (0.157 inch) holes according to your clip design. Screw-type rivets are recommended for easy and tool-free modifications to the board with clips.

Rivet sizes:

- A: 4mm (0.157 inch)

- B: 6mm (0.236 inch)

- C: 10mm (0.394 inch)

- S: 4mm (0.157 inch)

-

For more open-source content, please consider engaging through sharing, subscribing, liking, following, or commenting.

More information is available here: linktr.ee/plastmakers

Thank you.

Tom

Materials

- HDPE plastic (Guide reference)

- PP (Polypropylene)

- PLA (bioplastic option)

- Colored plastics/bottle caps (experimental)

- Mold release agent/oil (smoke point >230°C/446°F) ¹

Tools & Hardware

- M6x45mm bolts (4+ units)

- M6 washers/nuts

- Smooth sandpaper (for mold prep)

- Drill with 4mm bit (M4 holes)

- Screw-type rivets (4mm/6mm/10mm sizes)

Equipment

- IKEA Görlig electric oven (Example)

- Heat-resistant timer

- Clamping system (for mold pressing)

- Knife (edge trimming)

Safety Gear

- Heat-resistant gloves (oven handling)

Design Resources

- 3D blueprints (user-provided steel templates)

- Open-source guides: Plastmakers Hub

Quantities derived from 315x230mm board specifications.