Large Craft Sheet Design

Materials Needed:

- Sheet press

- 1.76 lbs (800 grams) granulated plastic

- 1 aluminum frame

- 2 aluminum base plates

- Stanley knife and paint scraper (for gently separating the aluminum plates)

Process:

- Cooking: 20-30 mins

- Cooling: 20-30 mins

- Tidy up: 5-10 mins

Table of Contents

-

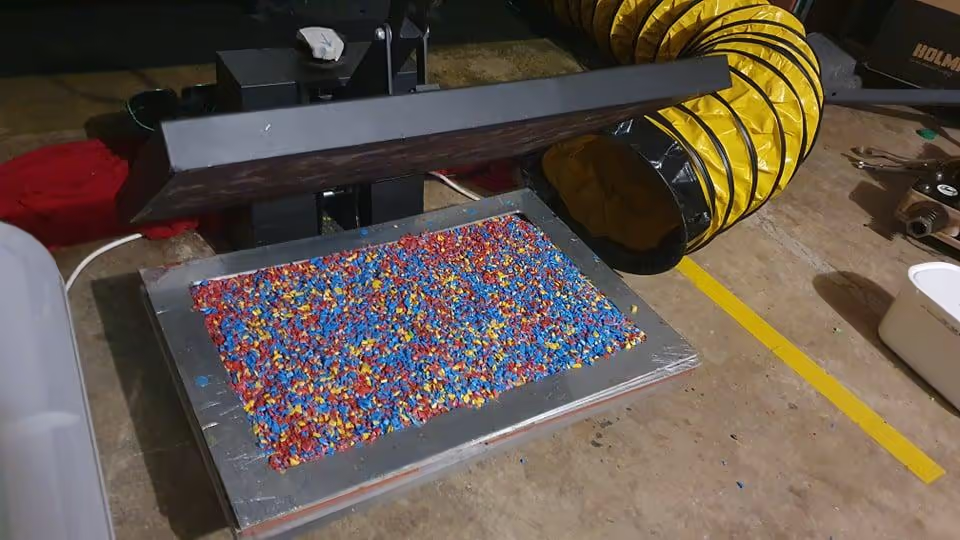

You require two base plates and one aluminum frame. A thick border is advisable to reduce bending. Place one base plate with the aluminum frame, evenly fill with plastic granules, and position the other base plate on top to form a sandwich before closing.

-

Turn on your machine. Set the temperature based on the plastic; for HDPE, use 392°F (200°C).

Close the machine tightly until you hear a click, adjusting the top knob as necessary.

-

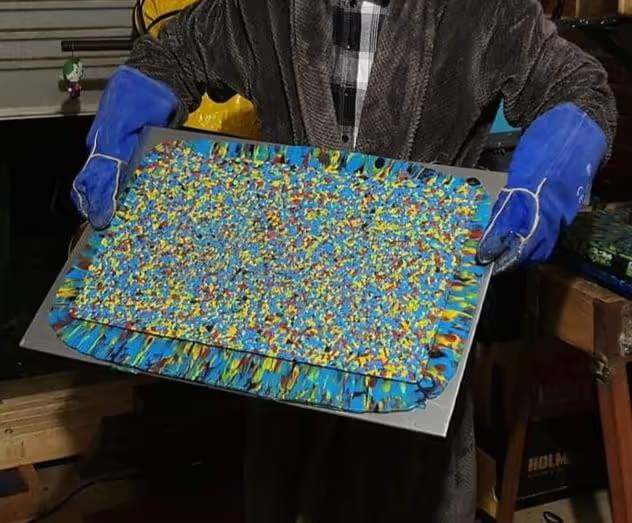

Melting takes 20-30 minutes. Once done, remove the aluminum plates and place them on concrete, adding another slab on top for compression. Additional weight is beneficial. Allow to cool for 30 minutes to avoid potential issues.

- 4Tidy up

Use a paint scraper to gently separate the plates. If you discover an improved method, please share it. A Stanley knife can help free a stuck sheet; carefully trim the edges for a clean result.

-

Instructions

Upon completion, explore colors and patterns.

For inquiries, please contact Zero.plastics.australia@gmail.com.

Visit us at www.zeroplasticsaustralia.com.

To create a large craft sheet using the described method, the following tools and equipment are required:

Tools

- ~~Stanley knife~~

- ~~Paint scraper~~

Software

- Not explicitly mentioned in the tutorial

Hardware

- ~~Sheet press~~

- ~~Aluminum frame~~

- ~~Aluminum base plates~~

All listed items are sourced via the provided tutorial materials and linked to the manufacturer’s website for reference.