Crafting Valuable Objects with Wood Joint Techniques

Learn to work with sheets to create valuable objects using wood joint techniques.

Table of Contents

-

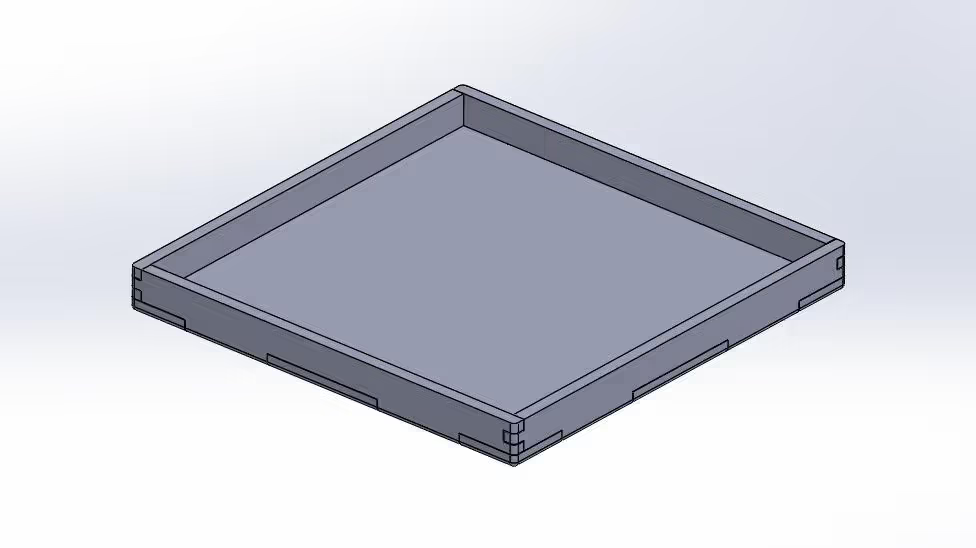

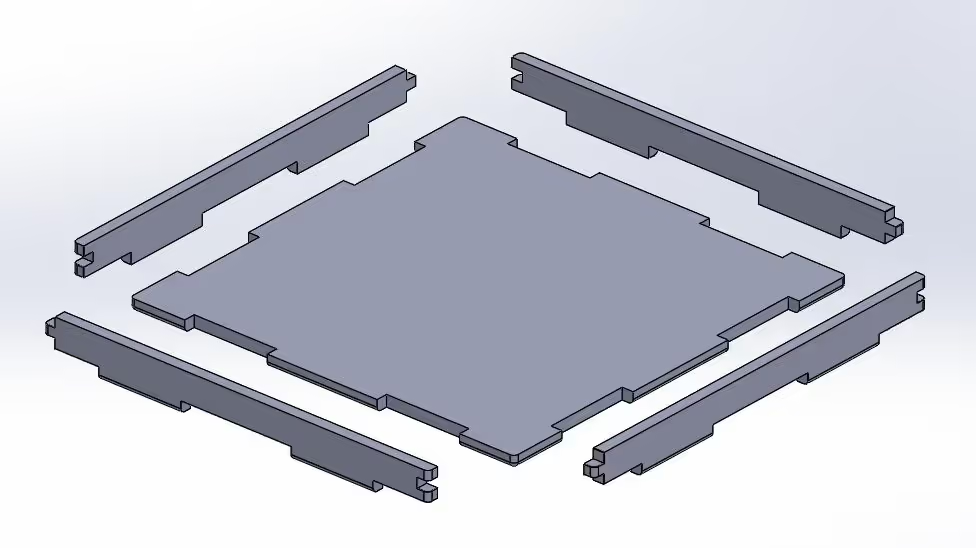

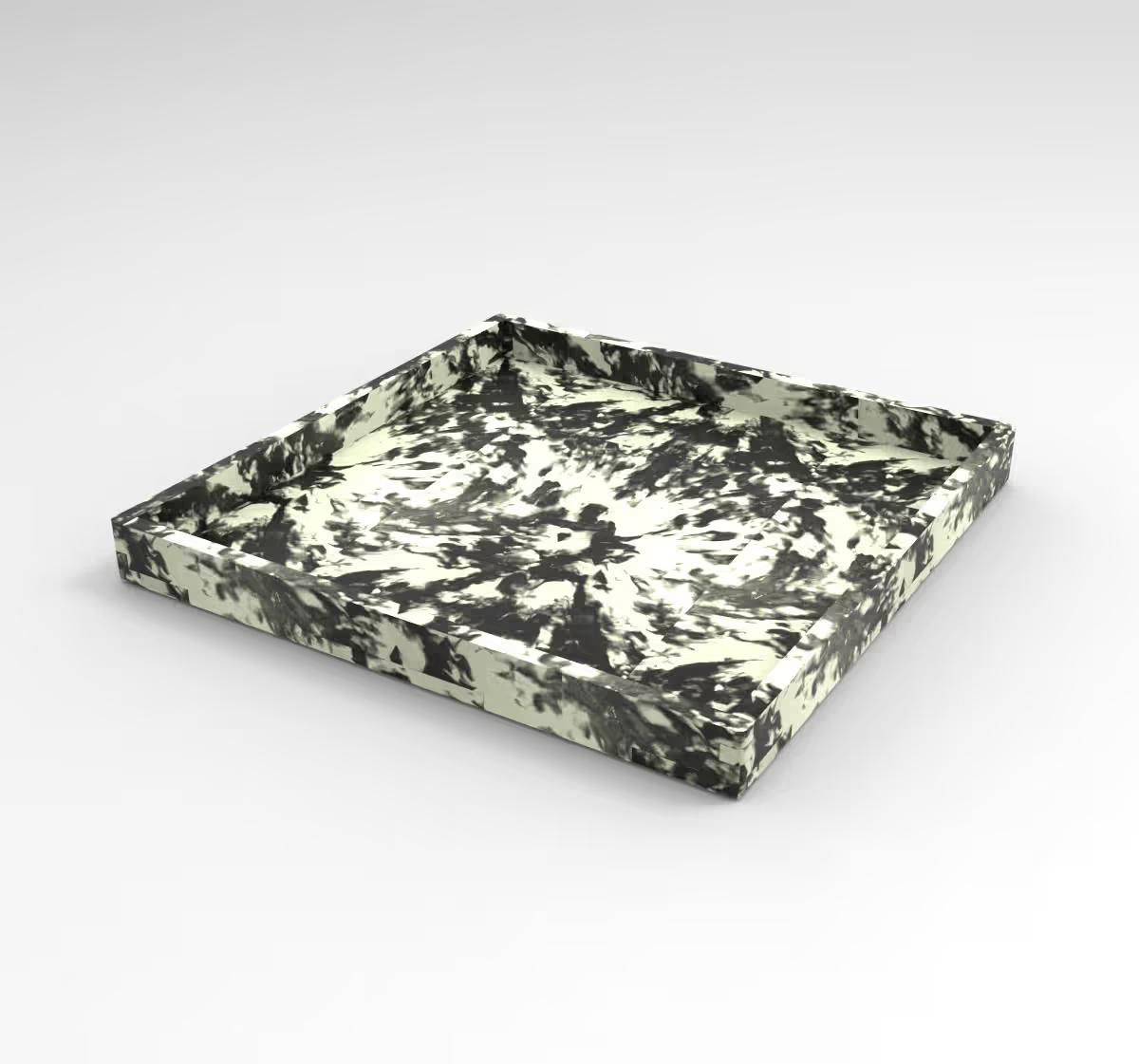

In this instance, we used Solidworks to model and render the product, allowing us to export the needed patterns for client review and approval.

-

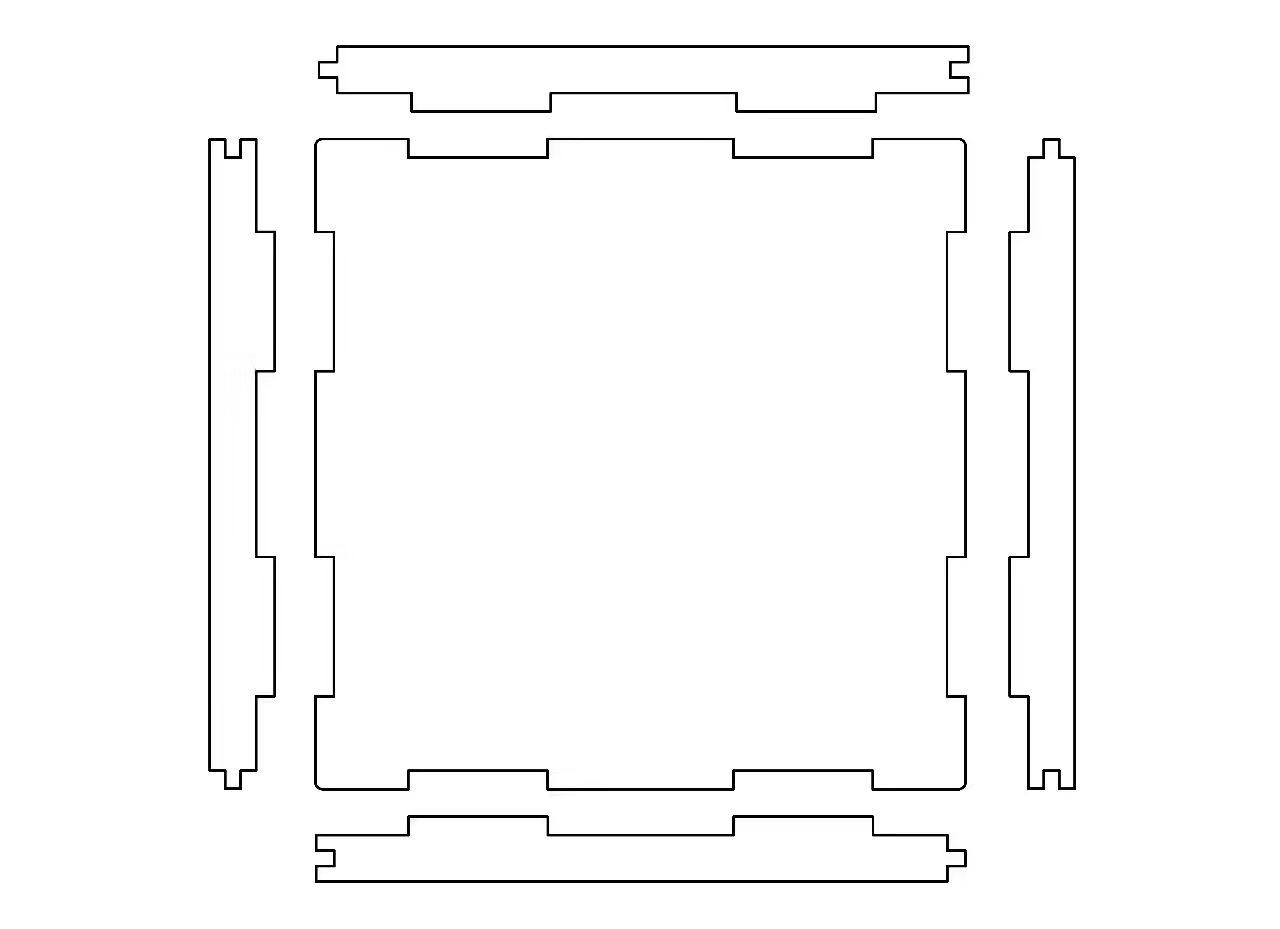

Accurate cuts are essential for quality joints.

-

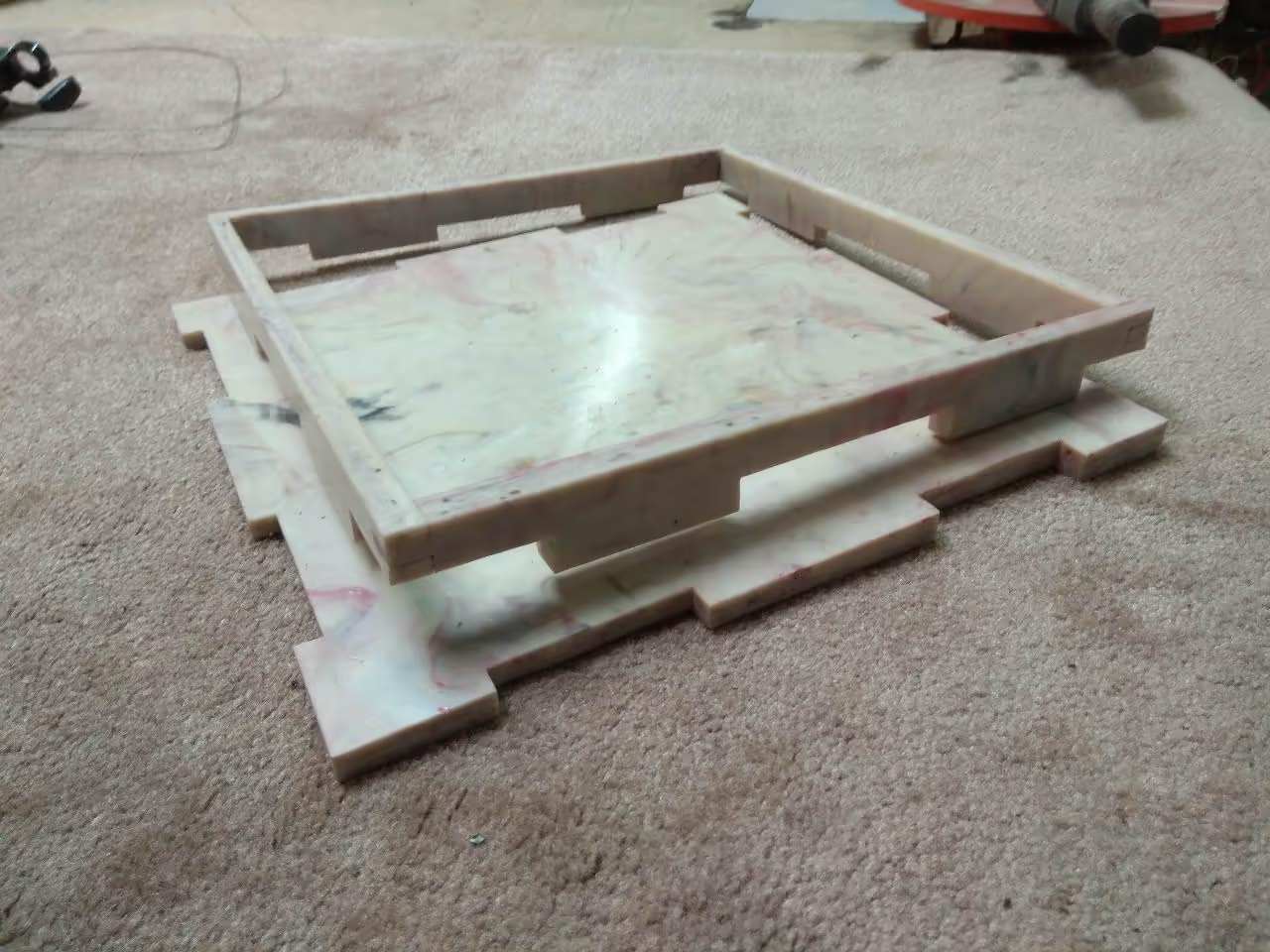

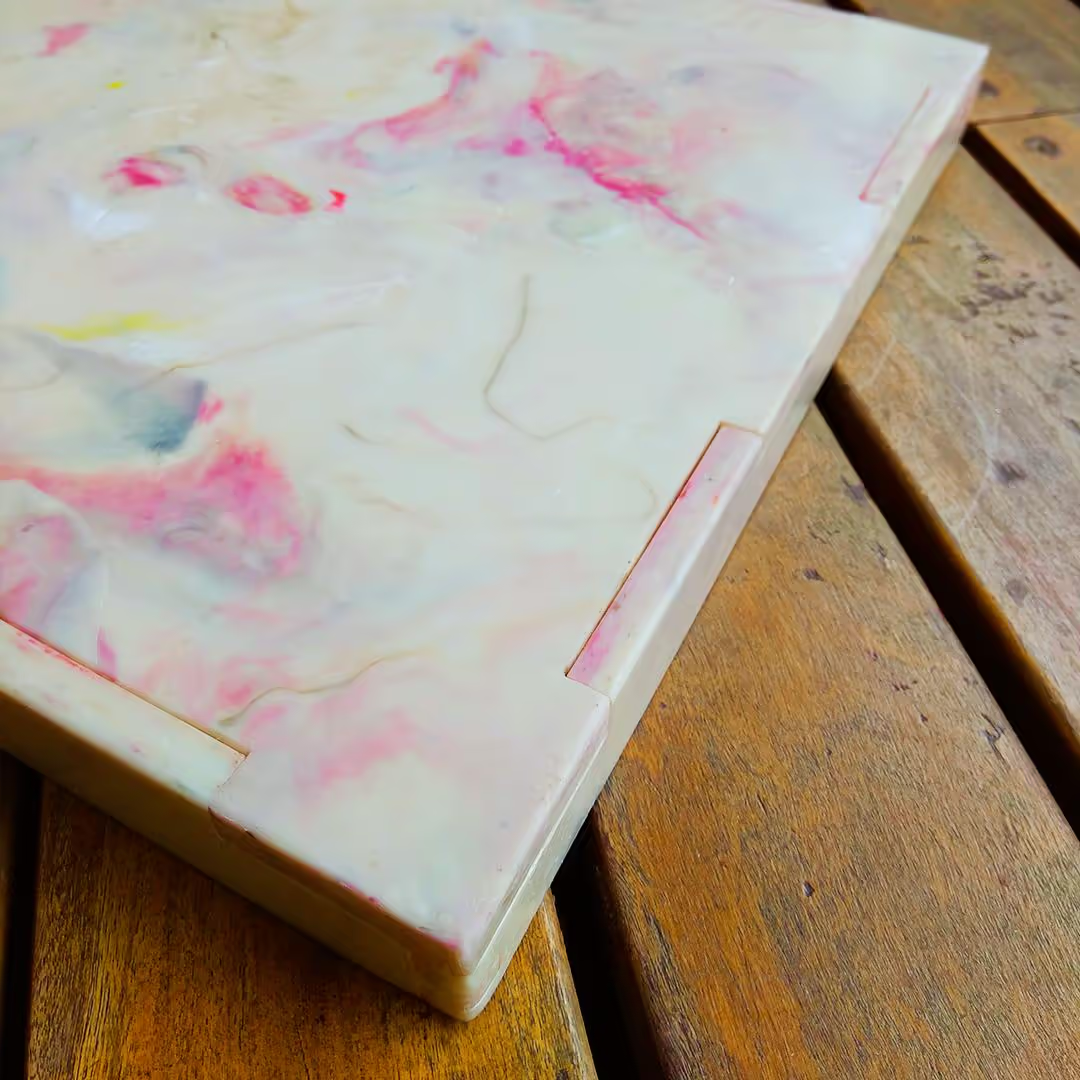

Once the PLA sheet is made, cut it into the five pieces needed for the product. The precision of the cuts depends on the tool used. We used an endless saw, resulting in rough cuts, which we then refined with a CNC router.

-

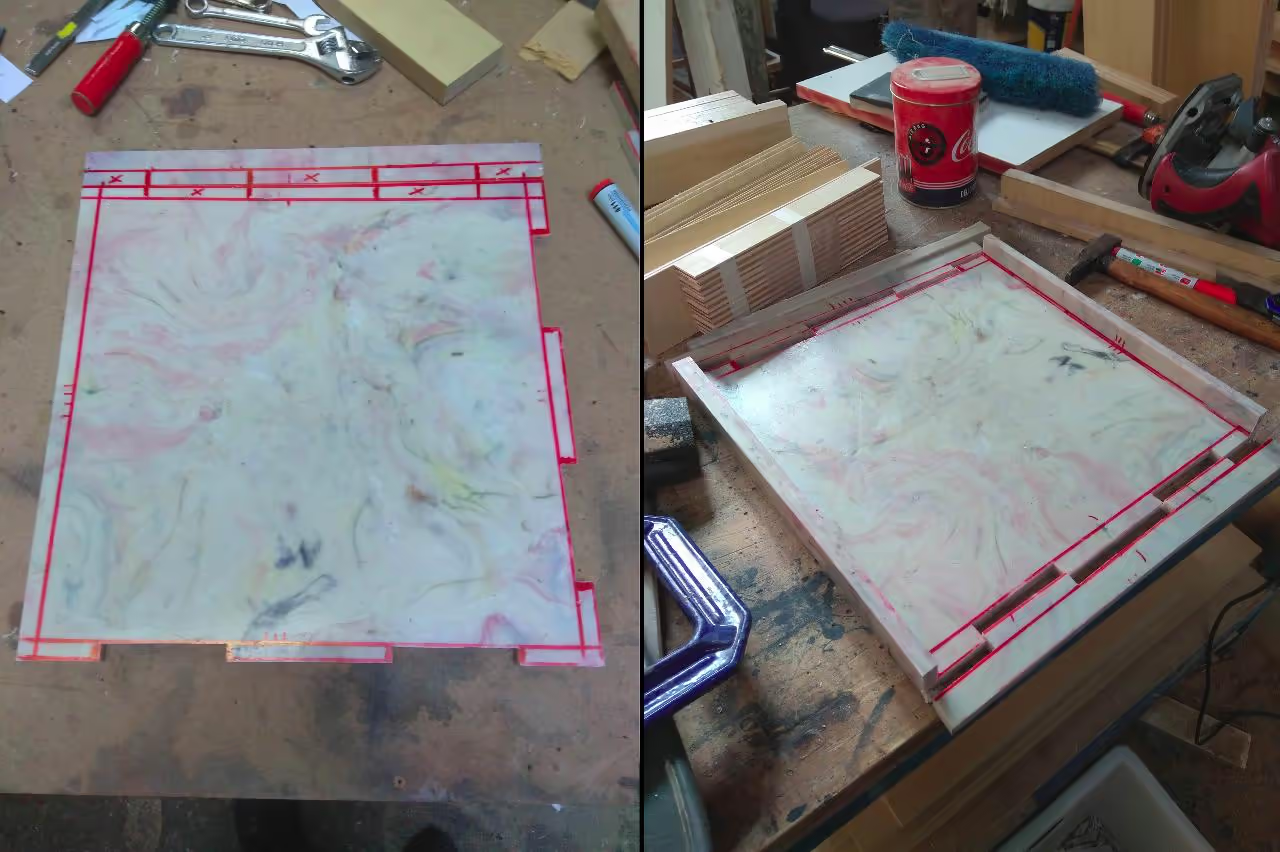

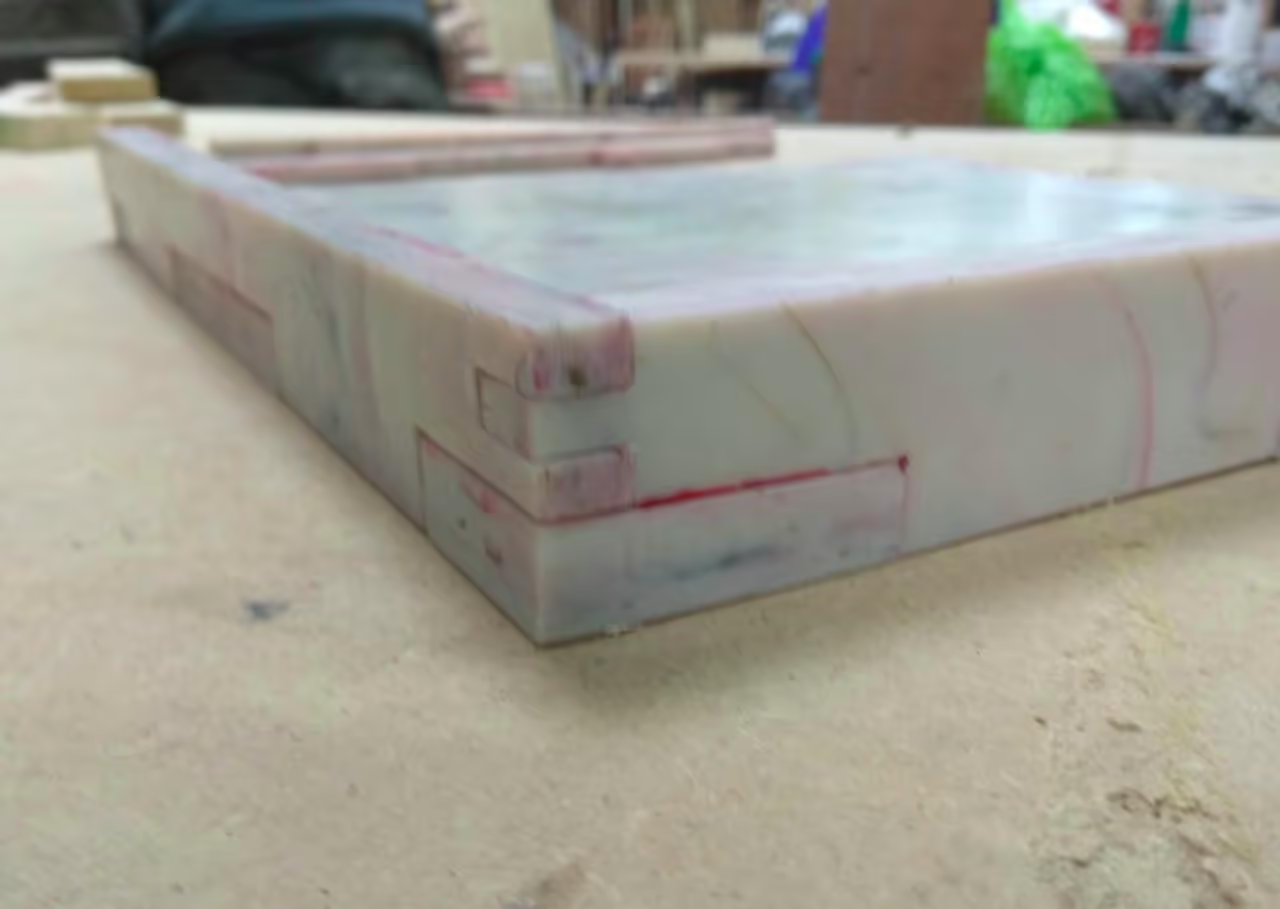

First, transfer all markings to the pieces and begin cutting. It is crucial to cut slightly less than needed initially, then test the joint. Trim more as required and repeat until achieving a perfect fit. Additionally, we used a file to smooth edges and make minor dimensional adjustments.

-

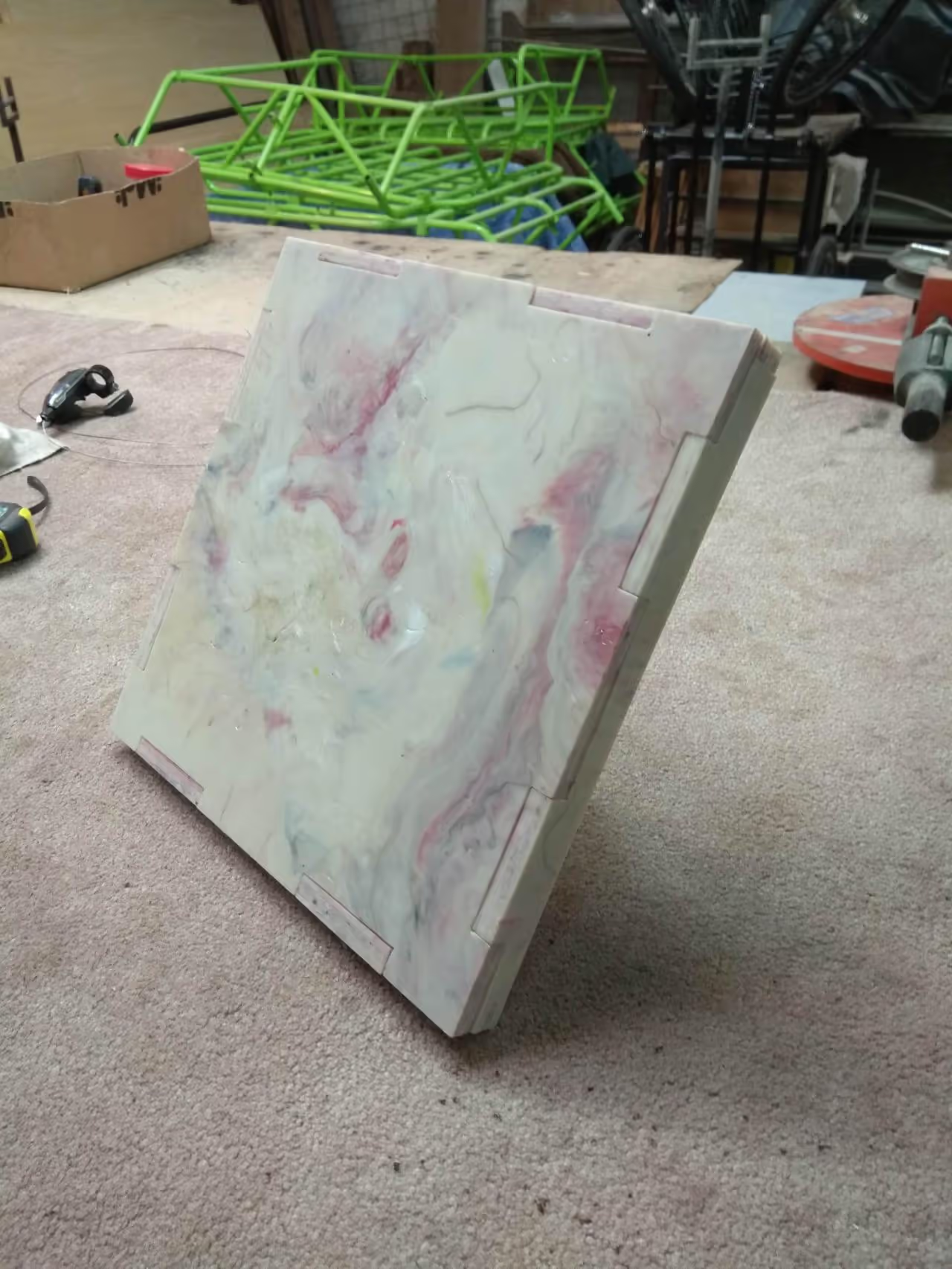

Once fit properly, use a heat gun and spatula to weld joints, ensuring the tray remains sturdy.

-

Contextualize and Provide Details

More photos available here.

Software

- SolidWorks (used for 3D modeling, rendering, and exporting patterns) [1]

Hardware

- Endless saw (for initial rough cuts)

- CNC CNC Router (for precision refinement of cuts)

Tools

- File (to smooth edges and adjust dimensions)

- Heat gun (for welding joints)

- Spatula (used with heat gun to fuse joints)

Additional photos and process details are available here.

References

Articles

- What To Know About Wood Joints - This Old House

- Joinery Techniques: Mastering Traditional Wood Joints

- The Ultimate Guide to Woodworking Joints - Wagner Meters

- When Ancient Meets Modern: Your Guide To Wood Joints - RealCraft

- 9 Types of Wood Joints - Kreg Tool

- 12 Essential Wood Joints for Your Next Project

- ~~Common Methods for Joining Wood - Homedepot.ca~~

- ~~Forming the Right Connections: Types of Joinery~~