Amid a global shortage of protective equipment, individuals with access to a 3D printer can assist by producing face shields for frontline workers. This design allows you to create face shields using a PET bottle.

For assembly instructions, view the video here: https://www.youtube.com/watch?v=6u6y6gD17rk

Table of Contents

-

To create the shield, 3D print the top and bottom parts. Download the files for free from websites like Thiniverse or Prusa, or access them from the zipped folder provided here.

-

You can use a standard white elastic band, but one with buttonholes is preferable.

-

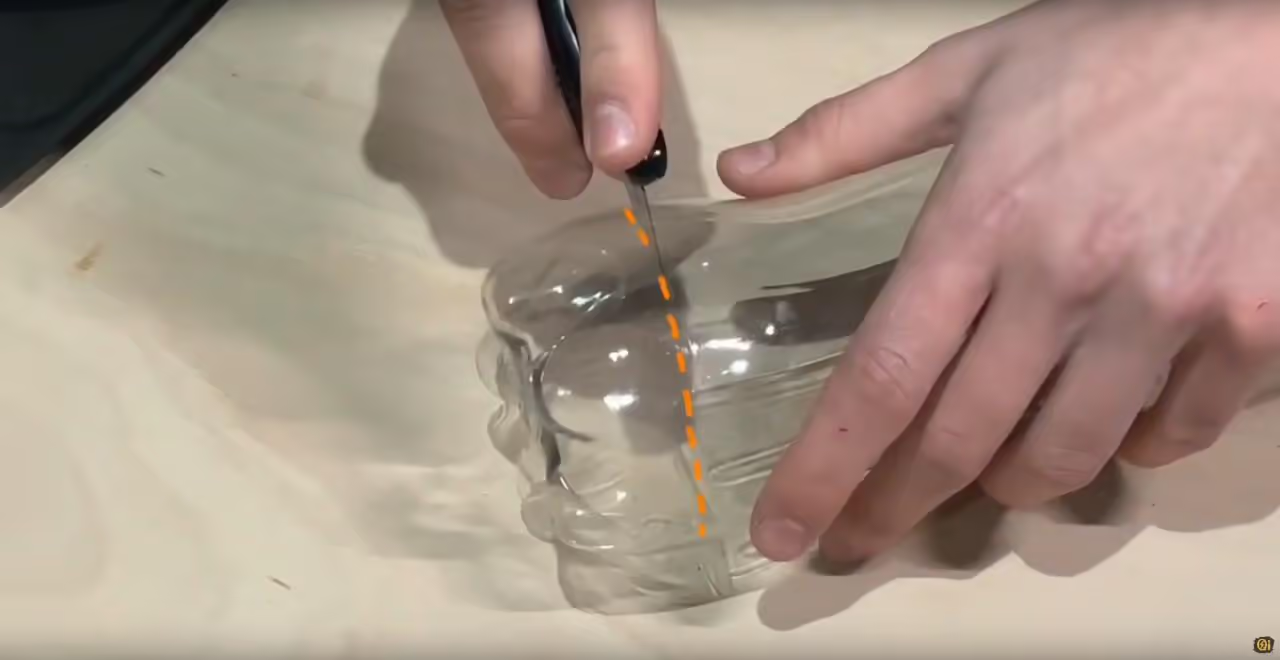

First, wash the bottle. Then, cut off the top and bottom. Finally, cut the side to open the plastic.

-

Instructions for Assembling the Bottle

-

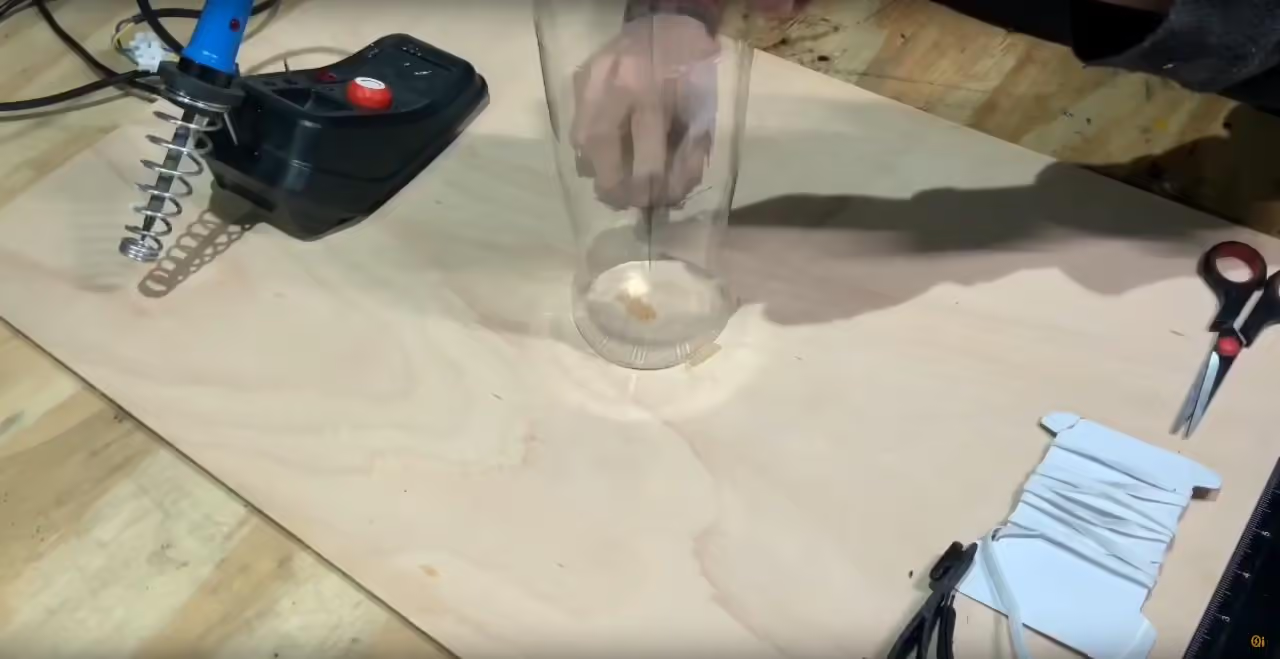

Prepare the Bottle Base

Open the PET bottle and insert it into the slit at the bottom. Use a soldering iron to melt the PET and printed parts at three visible interior points. -

Attach the Top Part

- Mark where to create holes in the bottle using a marker.

- Melt the holes with a soldering iron.

- After securing the top part, further melt the plastic together for enhanced durability.

-

-

Use nail scissors to round the corners at the bottom of the PET shield. Normal scissors can be used as an alternative.

-

Firstly, cut approximately 6-8 inches (16-20 cm) of elastic band. Securely tie the band around the holders on both sides.

-

Disinfect the inner side of the shield to remove bacteria. PRUSA provides a Sterilization Guide for further details.

To create DIY face shields using the described method, the following tools and materials are required:

Hardware

- 3D printer for producing top/bottom parts

- Soldering iron for melting PET/plastic components Video Guide

- Nail scissors or regular scissors

- PET beverage bottles (cleaned and cut)

- Elastic band (preferably with buttonholes)

Software/Files

- 3D printing files from Thingiverse or Prusa

- Assembly video tutorial

- Zipped design files from tutorial source

- Prusa Sterilization Guide

Tools/Materials

- Permanent marker for hole marking

- Disinfectant for inner shield surface

- Plastic-cutting tools

- Hole-punching equipment (soldering iron)

- Fastening elements (buttonhole elastic recommended)

Articles

- ~~Turning Recycled Plastic Bottles into Face Shields for Better Protection~~ [3]

- Make a DIY Face Shield Out of Plastic Soda Bottles [4]

- Can You Really Sterilize A 3D Print? Real Answers From Actual Studies [10]