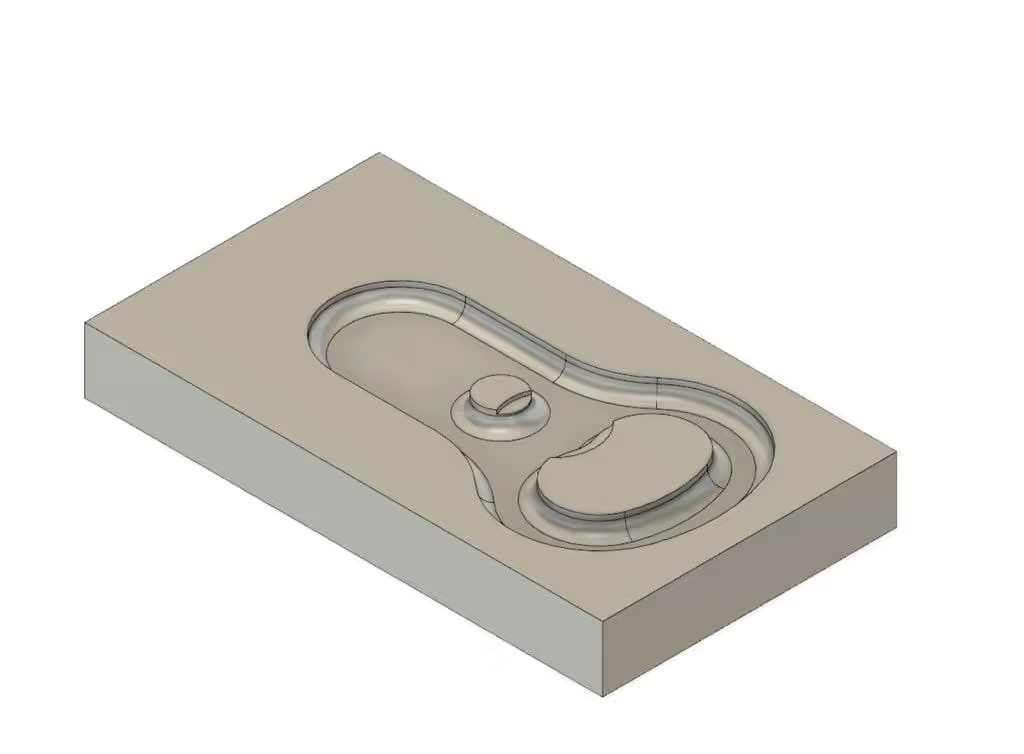

This guide provides information to create a Coin Bottle Opener.

The design accommodates a 10 Swiss cent coin, but you can adjust the parameters in the Fusion file for a different coin.

This model can be used for giveaways or workshop products. For selling the openers or molds, please contact the designer.

Table of Contents

-

The opener is designed to accommodate a 10 Swiss cent piece.

Adjust the parameters to match your coin's dimensions carefully. Incorrect measurements may cause the mold to leak, as it will not close properly, leaving a gap (if the coin is too wide) or allowing material to cover the coin (if the coin is too thin).

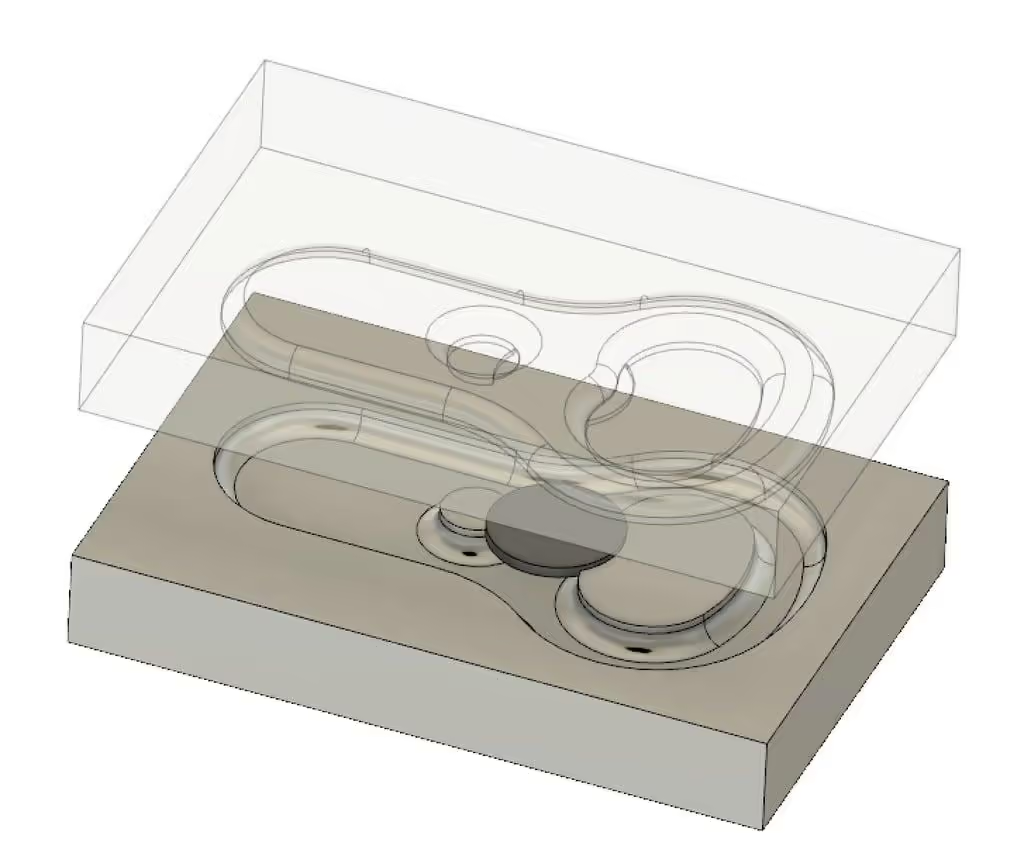

Modify the necessary parameters for CNC milling.

-

Adjust CNC milling parameters appropriately. Consult with an experienced individual in your community or consider ordering the mold from a workshop.

Material: Aluminum/Steel

-

Mould Material and Usage

- Material: Aluminum

- Longevity: Used for 5 years, shows scratches but remains effective.

- Alternative: Steel for extended durability.

Plastic and Color Recommendations

- Plastic: Polypropylene

- Performance: Optimal results.

- Color Mixing:

- Preference: Mixed colors, especially transparent.

- Popularity: Black/white combinations are favored.

Injection Process

- Ease of Use: Mould design allows straightforward injection.

- Heating: Rarely needed due to the mould's compact shape.

- Key Consideration: Ensure adequate pressure; insufficient pressure may cause plastic not to adhere properly at the base, resulting in an incomplete finish.

- Material: Aluminum

To create a Coin Bottle Opener, ensure you have the following tools, software, and hardware:

Software

- Fusion 360 for design customization and CNC parameter adjustment[1][5].

Hardware

- CNC Milling Machine for mold fabrication[4][5].

- Aluminum mold material (durable, scratch-resistant)[3][6].

- Steel mold material (longer-lasting alternative to aluminum)[3][6].

Tools

- Injection Molding Machine for plastic part production[6][8].

- Calibration Tools to ensure precise coin dimensions (prevents mold leaks)[2][4].

- Pressure Application Tools to secure plastic adhesion during injection[8].

- Material Handling Equipment for polypropylene plastic[7].

- Color Mixing Tools for transparent or black/white combinations[7][8].

Articles

- Custom Challenge Coin Bottle Opener - Pitch and Rudder

- Unique and Oddly Shaped Bottle Opener Coins

- Custom Bottle Opener Challenge Coin | Embleholics

- Bottle Opener Challenge Coins

- Custom Bottle Openers – Coin Depot

- Five Creative Custom Challenge Coin Bottle Openers