How to Prepare a Stool with a Low-Cost Mould

This guide demonstrates how to create a stool using an inexpensive mould. A simple cake tin replaces a more complex mould effectively.

Table of Contents

-

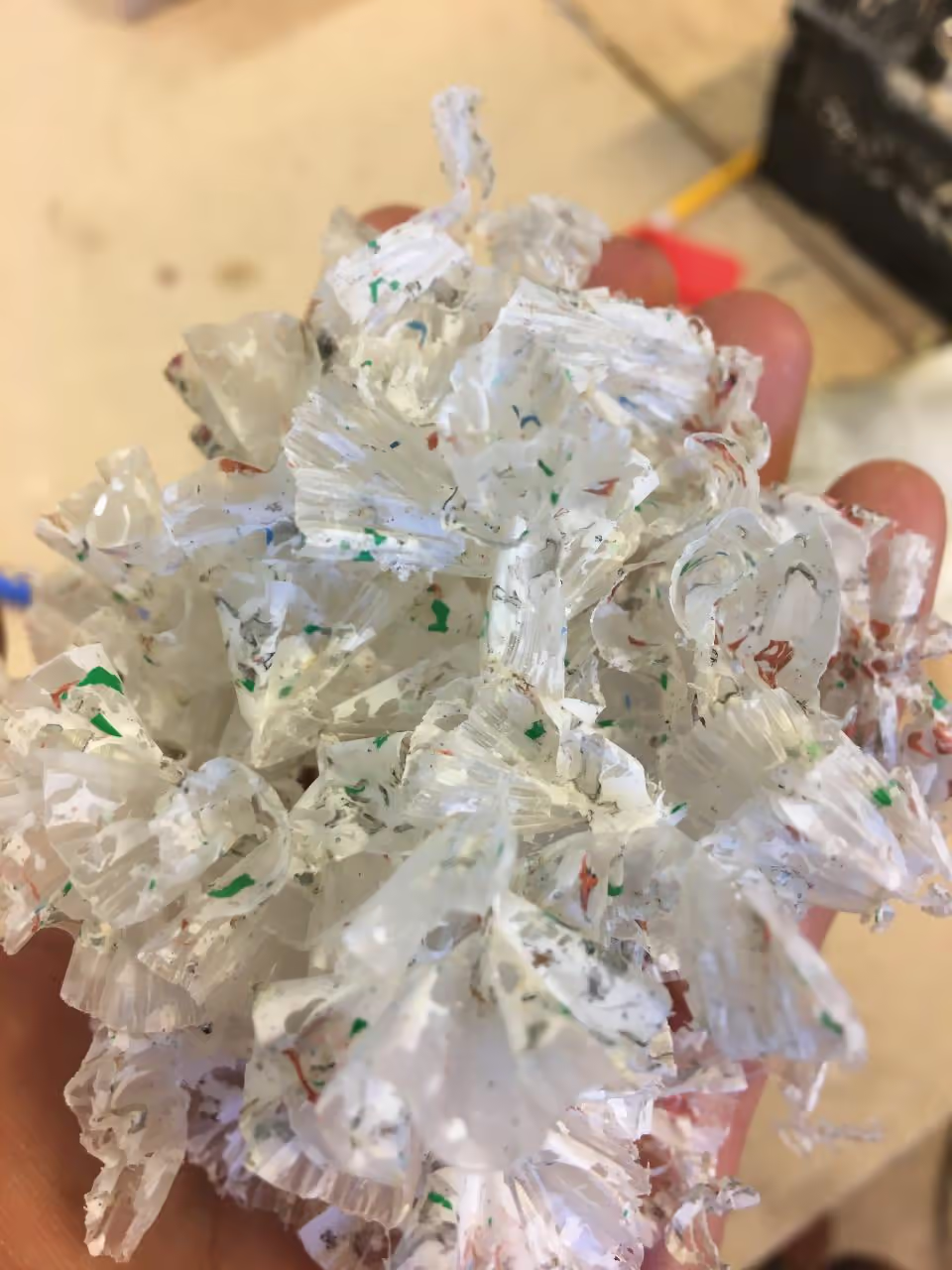

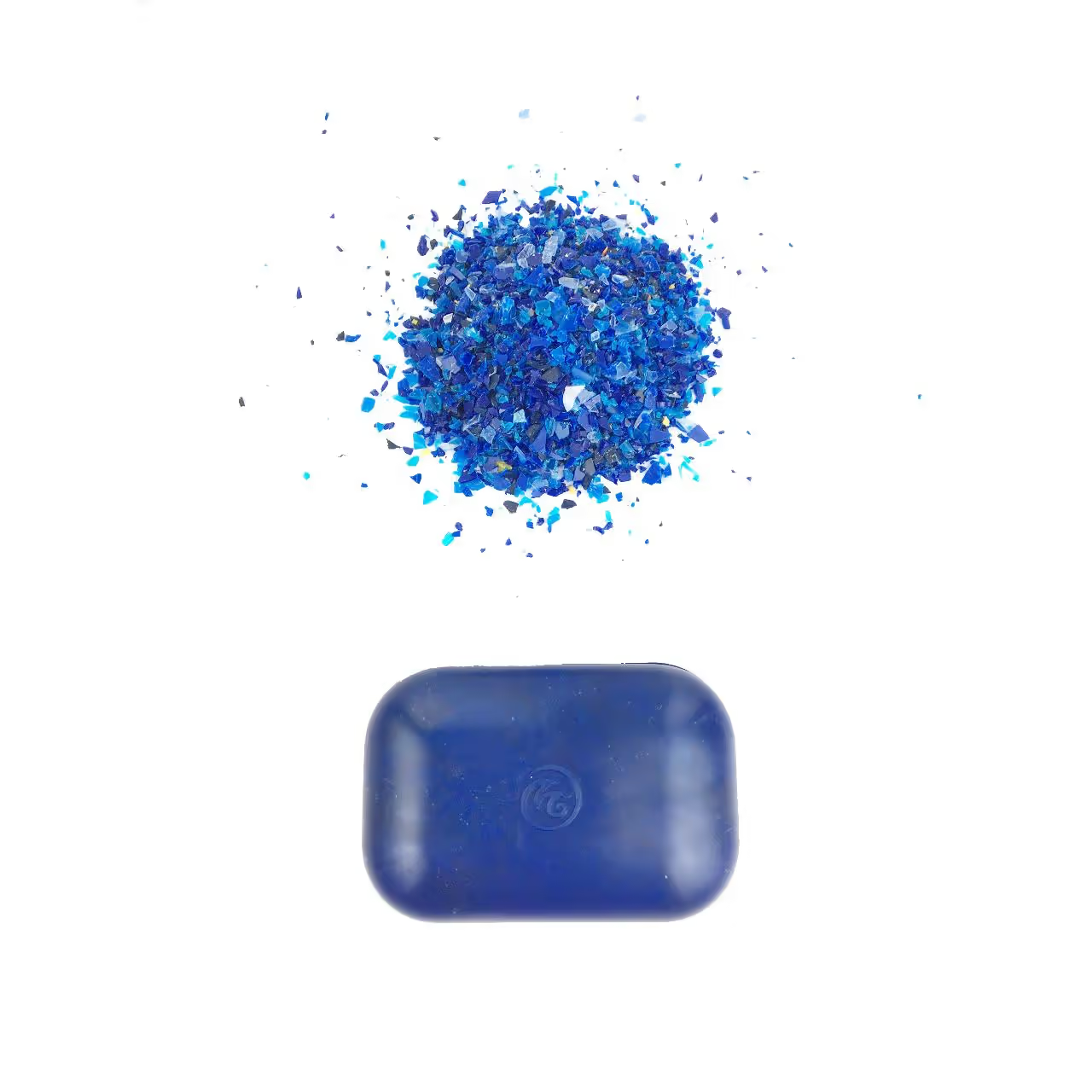

Before starting, decide which plastic to use and how to obtain it. We commonly use PP or HDPE, collected locally in Berlin. If plastic flakes are unavailable, seek alternative sources.

-

Custom engineered molds can be expensive, especially under current conditions. Therefore, we use a simple cake tin as a prototype stool mold, as shown in the picture. It was obtained from a supermarket and functions adequately.

Attention: Verify if the bottom of the cake tin is level, as it will shape the top of your stool.

-

For our machine, we use an oven modified for compression. Place the mold inside and heat it to 250°C (482°F) for polypropylene.

-

Fill the cake tin with granulated material and place it in the oven. Bake for approximately one hour to ensure thorough melting. Remove from the oven and allow it to cool for another hour. Once cooled, open the tin and remove the seat.

To level the top surface of the seat, use an electric planer. Collect excess material for future use.

- 5Fix legs

Initially, we tried wooden legs but found them difficult to secure to the seat. Ultimately, we chose metal legs that can be easily attached beneath the seat.

Purchase the legs at a hardware store or online. They include screws. Evenly distribute the legs at the base of the seat and fasten them with the screws.

Once assembled, turn the stool upright and it is ready for use.

Tools

- Electric planer (for leveling the seat surface)

- Screwdriver (for attaching legs)

Hardware

- Modified oven with compression capability (heated to 250°C/482°F)

- Cake tin (reused as a mould, ensure a flat bottom)

- Metal legs with screws (purchased from hardware stores/online)

Materials

- Polypropylene (PP) or HDPE plastic flakes (locally sourced in Berlin)

- Granulated plastic material (for melting in the mould)

- Excess planed material (reused for future projects)

References

Articles

- Tips for Custom Stool Mold - FOW Mould

- DIY Injection Molding (Instructables)

- ~~How Plastic Stools Are Made (Inochi Global)~~

- Thanatos Stool Design Process (Philipp Aduatz)

- Household Plastic Stool Injection Mould (Chinaplas Mould)

Opensource Designs

- Low-Cost Stool Using Cake Mould ([filtered] Academy)