This tutorial explains how to use a winch to handle molds efficiently. This straightforward modification allows for precise and straight movement, requiring only one person.

Table of Contents

-

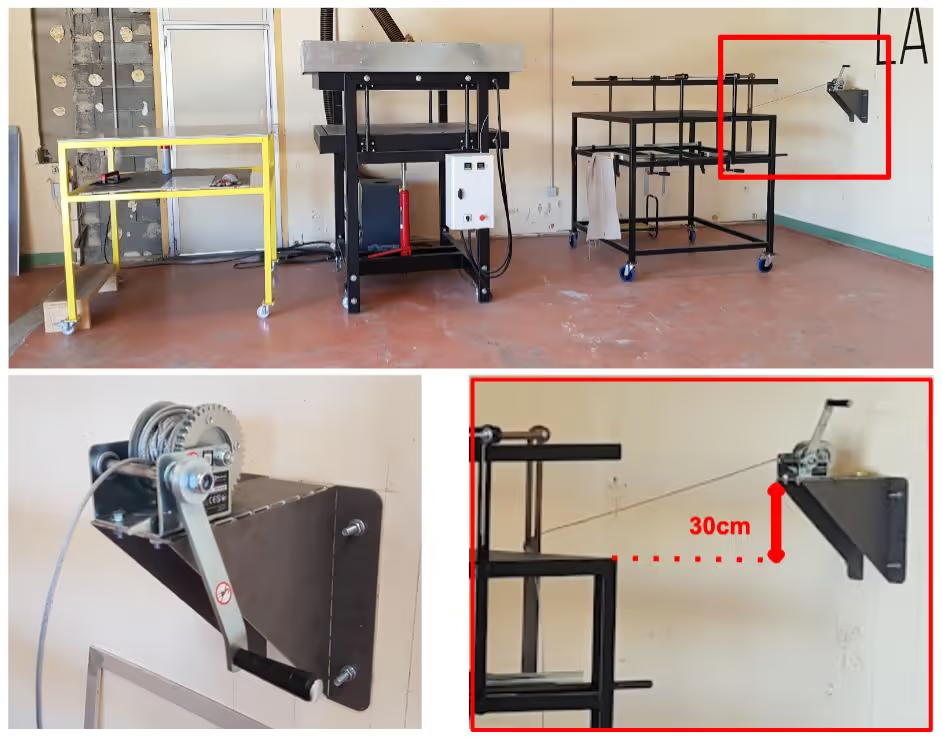

The manual winch (Einhell TC-WI500) is wall-mounted 11.8 inches (30 cm) above the preparation table, behind the Coldpress. Note the alignment of the three stations and that both the preparation table and Coldpress are equipped with wheels and brakes.

-

We resized the sheet metal to 120x125 cm (47.24x49.21 inches) for the hanging system.

-

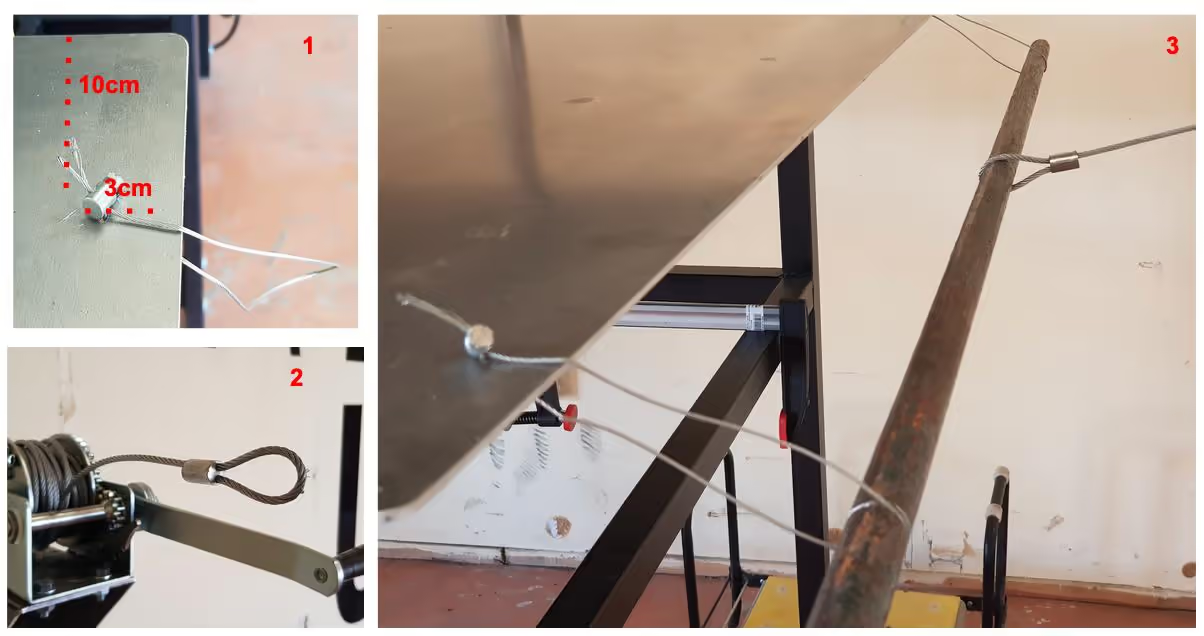

Holes were drilled in the sheet metal for a steel cable buckle.

-

The winch cable tip was also buckled.

-

Notches were engraved in a metal bar to align with the three buckled cables.

-

-

- Transferring the Mold to the Sheet Press

Unroll the winch from the wall to the preparation table, threading it through the cold press and the sheet press. Use a metal bar to attach the winch's buckles to the metal sheet.

Move the preparation table beside the sheet press.

Wind the winch to position the mold in the sheet press.

-

- Transferring the Mold:

After completing the heating cycle, move the cold press beside the sheet press and use the winch to transfer the mold onto the cold press.

-

To prevent friction and ease mold transfer:

- A polypropylene plate is used on the preparation table.

- When placing the mold between two tables, elevate the first table by 0.8 inches (2 cm) above the second.

- Ensure stations align with the winch cable to prevent mold rotation during pulling.

Here's an organized breakdown of the key components used in the mold-handling system:

Tools

- Einhell TC-WI500 manual winch (wall-mounted for cable control)

- Electric drill (for creating holes in sheet metal)

- Metal engraving tool (to carve alignment notches in bars)

Hardware

- Preparation table (mobile with wheels/brakes)

- Cold press machine (mobile with wheels/brakes)

- Custom-cut sheet metal (120x125 cm resized panel)

- Steel cable buckles (for winch-cable attachment)

- Metal bar with alignment notches (ensures straight cable positioning during pulls)

No specific software was required for this mechanical setup.

References

Articles

- Handling molds easily - [filtered] Academy

- How To Build A Winch Plate: A Comprehensive DIY Guide