HDPE Sheet Production Guide

Producing an HDPE sheet may become complex over time as unexpected issues arise during plastic handling. However, creativity and problem-solving can lead to successful project outcomes, even in academic settings.

Table of Contents

-

Acquiring supplies is straightforward as this material is commonly found in various containers, lids, and toys.

-

To melt plastic effectively, first cut it into small pieces. For home processing, use a blender. If this causes pieces to fly out, scissors and manual force can also work.

-

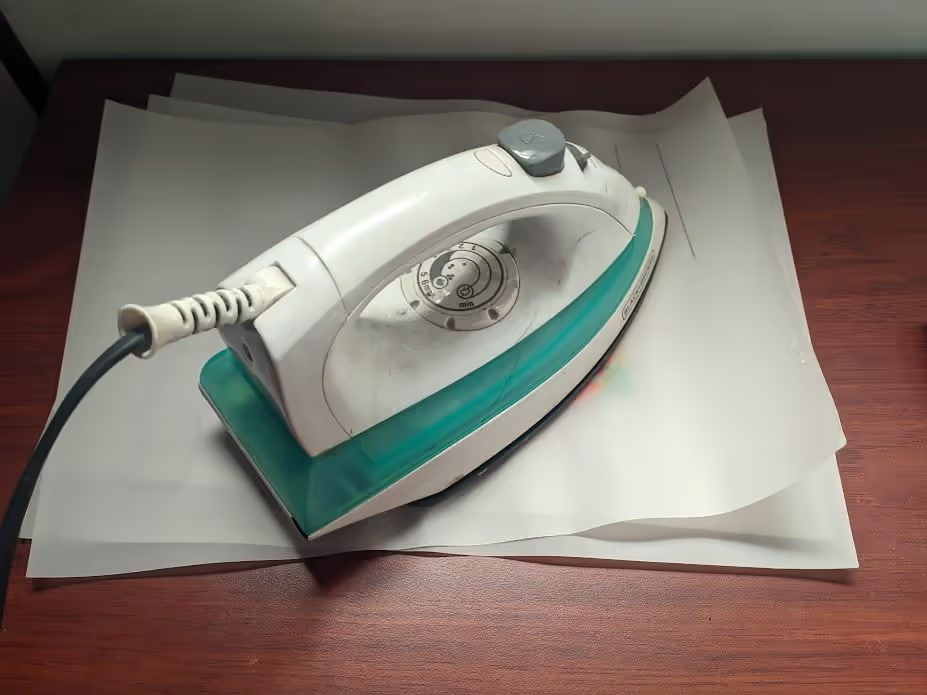

To melt HDPE, maintain a temperature above 275 degrees Fahrenheit (135 degrees Celsius). This can be achieved using a hot plate, hair iron, or clothes iron if a heat gun or more advanced equipment is unavailable.

- 4Outcome

In this tutorial, we will create a uniform plastic sheet to illustrate a basic approach to industrial plastic transformation from home.

To address the tools, software, and hardware required for HDPE sheet production based on the provided tutorial, here’s a concise breakdown:

Tools

- Blender (for shredding plastic into small pieces)

- Scissors (manual cutting alternative if blending is ineffective)

Hardware

- Hot plate (melting device for maintaining temperatures above 275°F/135°C)

- Hair iron (alternative for heating/pressing HDPE)

- Clothes iron (substitute for heat application and sheet formation)

- Heat gun (advanced heating tool mentioned as optional)

Software

- No software required (process relies solely on physical tools and equipment)

The tutorial emphasizes repurposing common household items for small-scale production, prioritizing accessibility.

References

Articles

- Sheets of HDPE Manufacturing Process and various Uses

- Recycled HDPE Sheets - Reprocessed Plastics, Inc.

- How Are HDPE Sheets Made?

Tutorials

- Learn how to recycle HDPE at home to make your own bowls

- Plastic Smithing: How to Make Your Own HDPE Plastic Anything