This tutorial explains how to build a bench using 2x4 extruded beams. The finished bench will weigh over 80 pounds (approximately 36 kilograms).

Table of Contents

-

This process requires the following tools and equipment:

- V4 Extruder

- 2x4 mold (1.5 in x 3.5 in x 6 ft)

- Approximately 85 lbs (38.6 kg) of shredded PP plastic

- Cooling tank

- Miter saw

- Drill

- Drill bits

- Deck screws

Once you have gathered all your materials and equipment, you are ready to begin.

- 2Prep

Ensure all plastic is thoroughly cleaned, sorted by type (and color if necessary), and shredded to the desired flake size. For our bench, we used PP (#5) plastic.

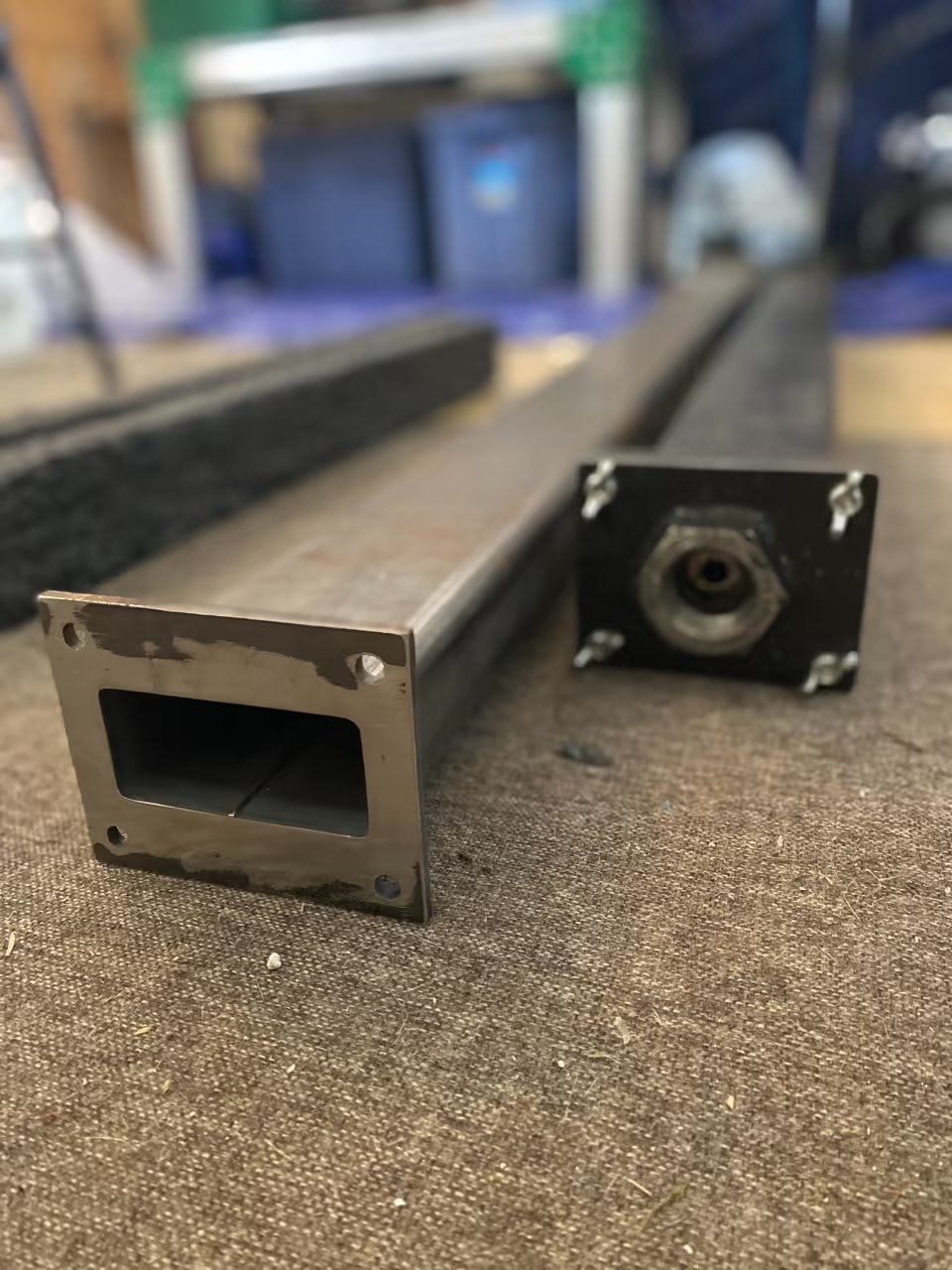

- 3Extrude

With the plastic prepared, it is ready for extrusion into beams. Set the extruder temperature to 240°C (464°F) for PP plastic. Attach the mold. Begin extruding at 45-50 RPM, ensuring the hopper remains filled. Once the 6-foot (1.83-meter) mold is filled, disconnect it and place it in a cooling tank with cold water for approximately 20 minutes. After the plastic solidifies, remove it from the mold. Repeat until you have eight 6-foot beams.

- 4Cut

The beams should first be trimmed to remove any excess material at the ends. Next, cut the beams to the specified dimensions using a chop saw:

- (4) beams, each 5 feet 4 inches (163 cm) for the Benchtop

- (1) beam, 60 inches (152 cm) for Ground Support

- (4) beams, each 16 inches (41 cm) for the Legs

- (6) beams, each 15 inches (38 cm) for the Braces

- (2) beams, each 11 1/4 inches (29 cm)

- 5Staging

Assembly Instructions

Lay out the four longest beams side by side to form the bench top, maintaining a spacing of approximately 0.25 inches (6.35 mm) between each. Attach the braces at the ends of the bench top.

- 6Assemble

At this stage, attach the beams using 2.5-inch (6.35 cm) deck screws. Pre-drill pilot holes to prevent cracking.

-

Begin assembling the bench on a tarp to collect drill shavings for potential reuse. Position the 16-inch (40.64 cm) beams at each corner as legs. Drill pilot holes and secure with screws.

-

With the bench top and legs prepared, the next step is to reinforce the structure. Position the 15-inch (38 cm) beams between the legs as braces. Next, use the 11 1/4 inch (28.5 cm) beams to install a perpendicular support, connecting the bench top to the 60-inch (152 cm) beam that spans the base.

- 9Enjoy!

Choose a suitable location to install your bench, such as a backyard or park.

To build a bench using 2x4 extruded beams, you’ll need the following items grouped by category:

Tools & Equipment

- V4 Extruder

- 2x4 mold (1.5 in x 3.5 in x 6 ft)

- Cooling tank

- Miter saw

- Drill & drill bits

Materials

- 85 lbs shredded PP plastic (#5)

- 2.5-inch deck screws

Hardware Components

- (4) 5'4" Benchtop beams

- (1) 60" Ground Support beam

- (4) 16" Leg beams

- (6) 15" Brace beams

- (2) 11.25" Support beams

These items cover extrusion, cutting, and assembly steps outlined in the tutorial. The process involves shredding plastic, molding beams, and constructing the bench with precise cuts and screws.

Articles

https://pri-plastics.com/understanding-plastic-extrusion-a-comprehensive-guide/

https://www.[filtered].earth/news/extrusion-machine

Books

https://www.barnesandnoble.com/w/extrusion-harold-f-giles-jr/1111448551

YouTube

https://www.youtube.com/watch?v=tGc-Z7TtiVg

https://www.youtube.com/watch?v=1A05nDBKzVc

https://www.youtube.com/watch?v=9Hmp4K3NwB0

Opensource Designs

https://community.preciousplastic.com/library/make-a-bench-with-beams