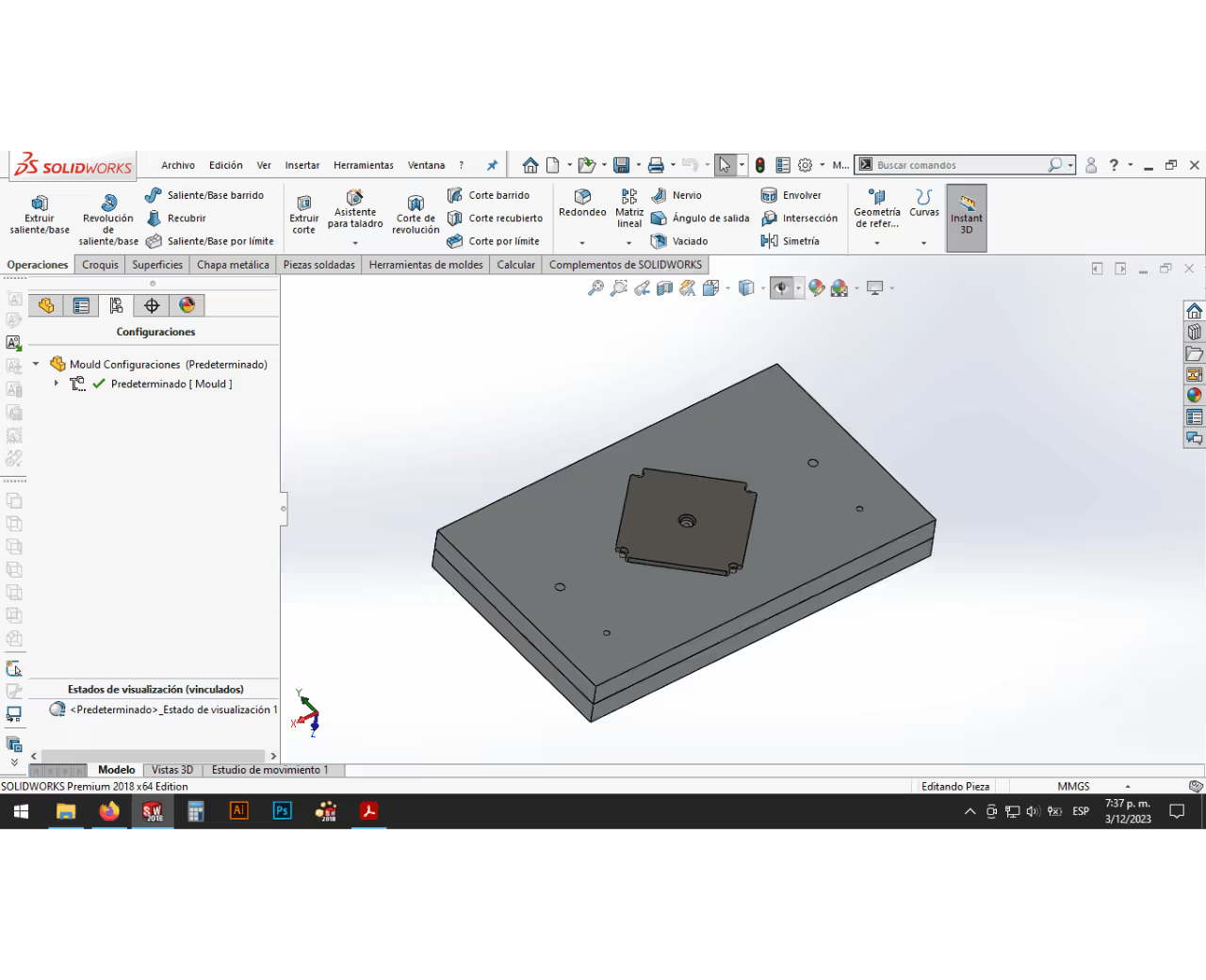

This is a CNC machined mold. Locate a suitable CNC provider and get ready to produce numerous hangers.

Table of Contents

-

Into the files, you will find:

- General drawings

- .IGES files

- .STEP files

- Parasolid files

- Solidworks editable file

-

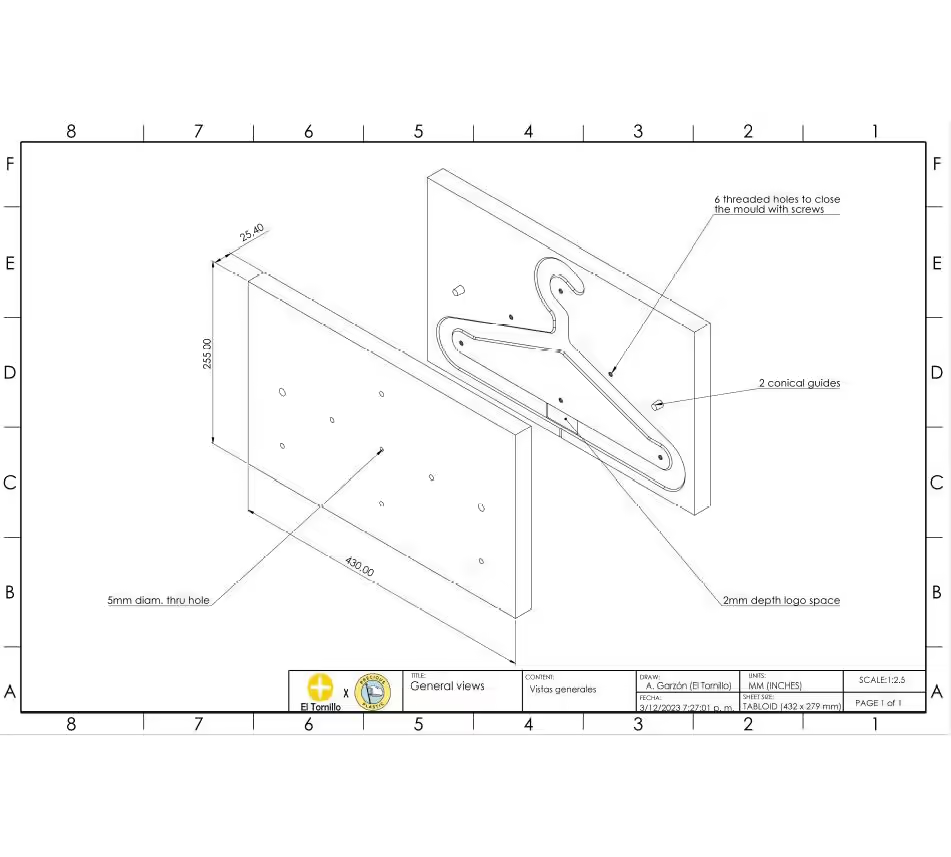

For the mold, two aluminum blocks measuring 430mm by 255mm by 25mm (16.93in by 10.04in by 0.98in) are required.

Contact a CNC machinist to fabricate the design files.

You can opt to include a cutout for a logo or keep it flat (both options are available for download).

For customization, modify the dimensions or other design aspects using the editable software file. Please share any innovations.

-

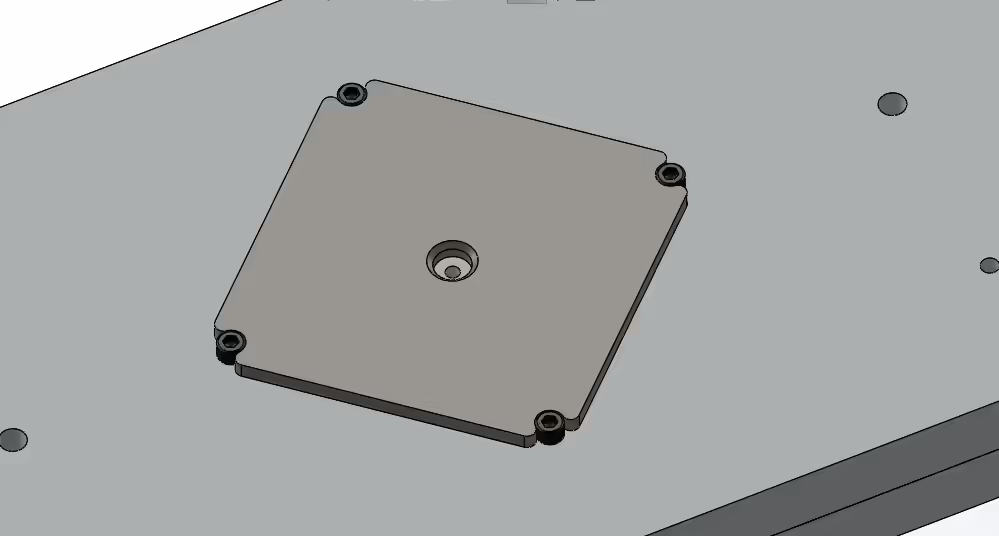

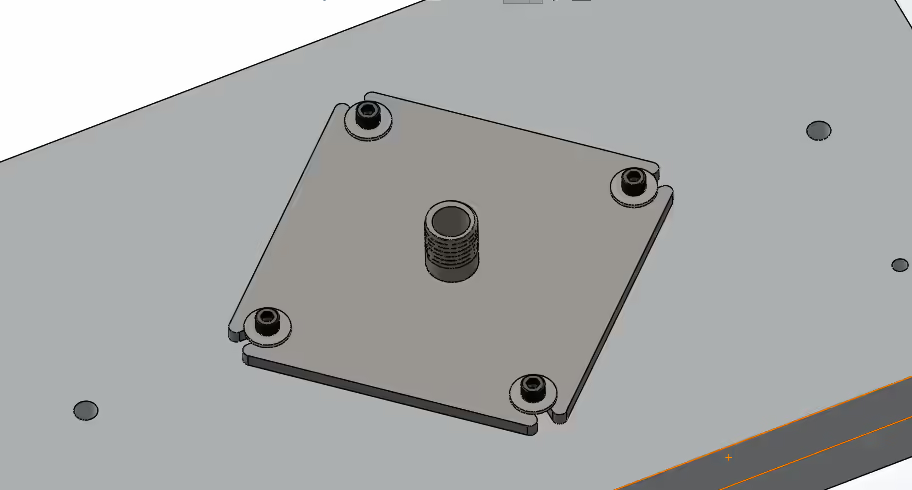

Nozzle and Flange Connection Guide

Select the appropriate flange for your machine nozzle to connect it to the mold.

-

Conical Nozzle: Use a flat 0.24-inch (6mm) flange with a bevel to receive the nozzle. Ensure it aligns with the screw heads through slots. It is not attached to the mold but pressed with a jack between the mold and nozzle.

-

Screw Nozzle: Weld the pipe connector to the flange and secure the flange to the mold using closing screws.

Adjust the design as necessary to suit your requirements.

-

-

If you decide to include logos in the mold, add the engraved sheet.

In this example, a metal sheet is engraved using acid etching, a process used in printing.

Trim and file the sheet to its final size, then fit it into the hole.

-

Heat the machine, insert the plastic, and inject to create your hangers.

The final weight is approximately 81 grams (2.86 ounces).

To facilitate the CNC mold production and injection molding process described, here are the essential components and resources:

Tools & Machinery

- CNC machining services (Thomasnet Directory)

- Hydraulic jack (for nozzle flange pressure)

- Metal trimming tools (files/shears for engraved sheets)

- Plastic injection molding machine

- Welding equipment (for screw nozzle flange)

Software

- CAD software (SolidWorks)

- File-compatible viewers for IGES/STEP/Parasolid (e.g., AutoCAD)

- Vector graphic software for logos (Adobe Illustrator)

Hardware

- Aluminum blocks (430×255×25mm / 16.93×10.04×0.98in)

- Conical nozzle flange (6mm thick with bevel)

- Screw nozzle flange with pipe connector

- Engraved metal sheet (acid-etched)

- Closing screws (flange attachment)

Materials

- 6061 or 7075 aluminum alloy blocks

- Injection-grade plastic pellets

- Acid solution for metal etching

- Stainless steel sheet (logo engraving)

- Fasteners (screws/pins)

Custom Tooling & Services

- CNC machinist (Colombian provider directory)

- Acid etching service (~~Local print shops~~)

- Custom flange fabrication (per nozzle type)

- Mold testing/validation service

- CAD modification specialists

All dimension modifications require updated SolidWorks files[1]. For Bogotá-specific machining options, consider industrial zones like Zona Franca de Bogotá[3]. Ensure aluminum blocks meet MIL-A-22771 standards for injection molds[2].

References

Articles

- CNC machines for efficiency in mold manufacturing - Thriam

- The ultimate guide to rear derailleur hangers | BMCR's blog

- CNC Basics: Easy Learning Guide

- Helpful Injection Molding Design Guidelines | GrabCAD Tutorials

- What are the CNC Techniques in Mold Making? - JTR China

- Essential Guide to Mold Making CNC: Techniques and Best Practices

Books

- ~~CNC Handbook | McGraw-Hill Education~~

- Fundamentals of CNC Machining - HAAS Technical Education Center

- The Homebrew Industrial Revolution

Papers

- The application of CNC machining technology in mechanical mold manufacturing (PDF)

- Mould design and manufacturing using computer technology (PDF)

YouTube

- Practical CAD Techniques for Composite Pattern/Mould Design

- How Wood Skateboard Molds are Made (CNC)

- Beginner To Advanced — How To Create a Mold— Part 1